Blank discharging device for large-section vertical continuous casting machine

A billet ejecting device and continuous casting machine technology, which is applied in the field of slab ejecting devices for large-section vertical continuous casting machines, can solve the problems of unfavorable overall quality of casting billets, low work efficiency, and large space occupied, and can reduce the height of the workshop, Space saving, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

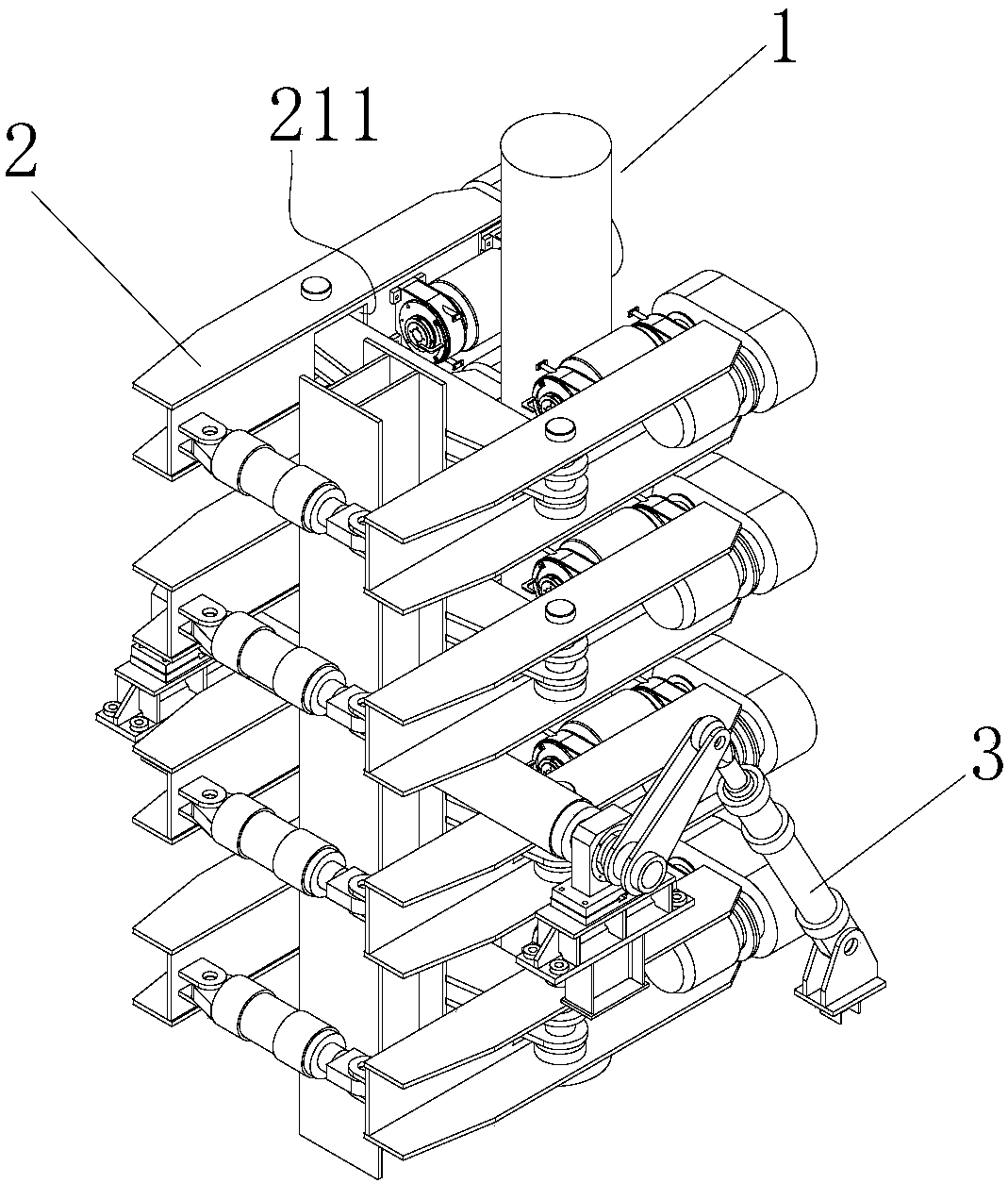

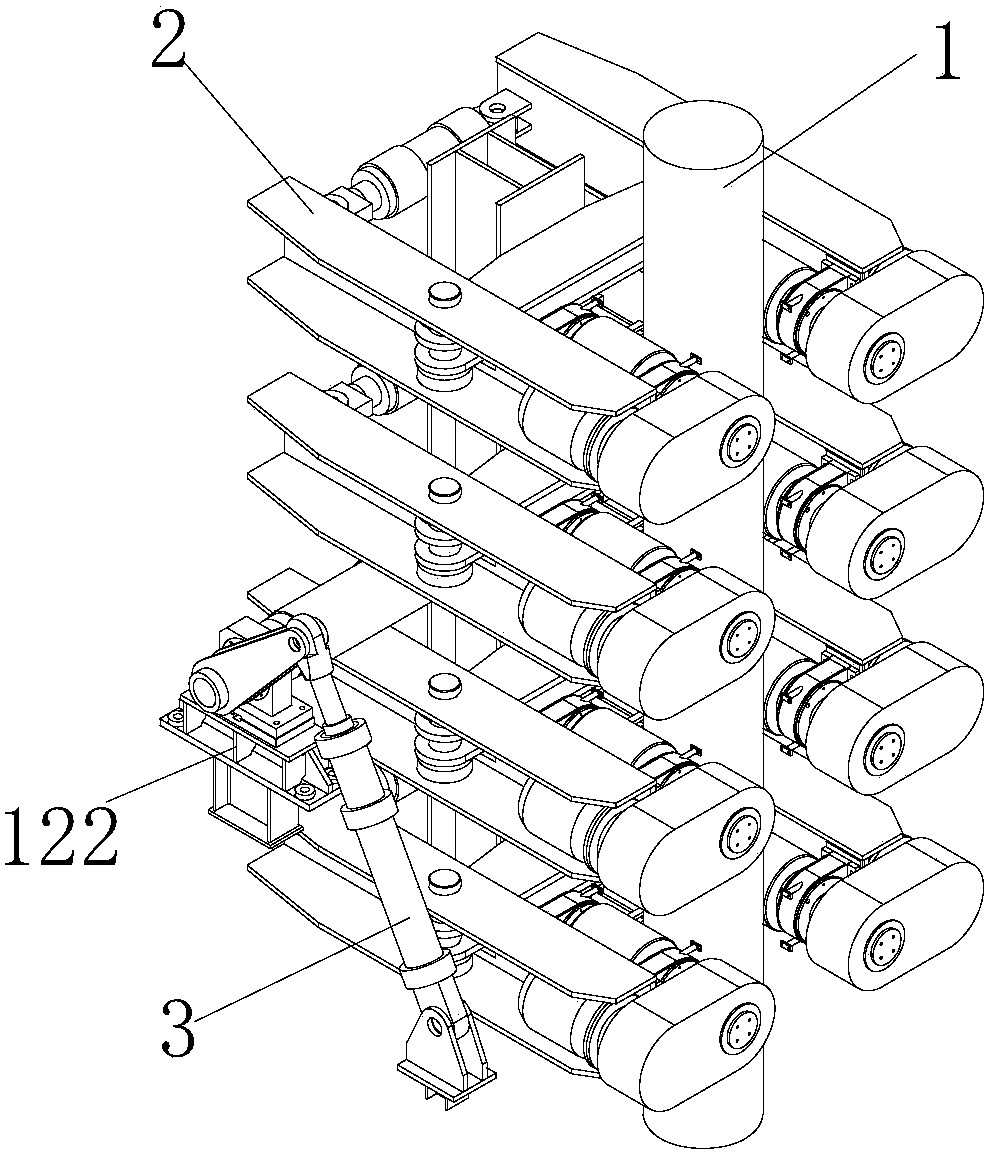

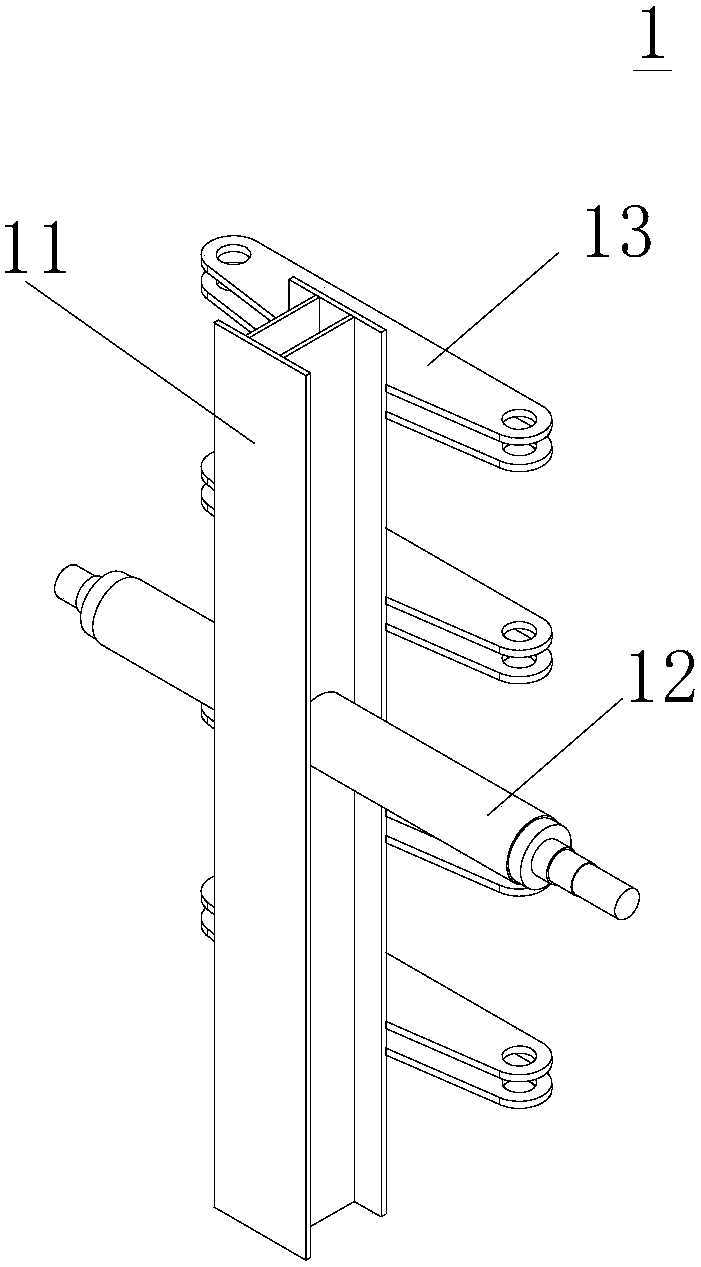

[0029] The present invention proposes a billet discharge device for a large-section vertical continuous casting machine, which includes: a supporting frame, which is provided with a column and a synchronous shaft, the synchronous shaft is horizontally arranged, and is fixed on the column; A plurality of clamping mechanisms are vertically spaced on the column. The clamping mechanism includes two parallel connecting rods. A driving roller is respectively installed at the front ends of the two connecting rods, and a driving roller is connected between the rear ends of the two connecting rods. Clamping the hydraulic cylinder, there is a bracket pivotally connected between the two, the bracket is parallel to the synchronous shaft, it is installed on the column, and the two driving rollers are set opposite to each other, and a gap is formed between the two for placing In the accommodating space of the slab, the axial direction of the drive roller is in the same direction as the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com