Space-saving ratchet unit with freewheel

A ratchet and flywheel technology, applied in the field of space-saving ratchet units with flywheels, can solve problems such as instability, and achieve the effect of reducing radial space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

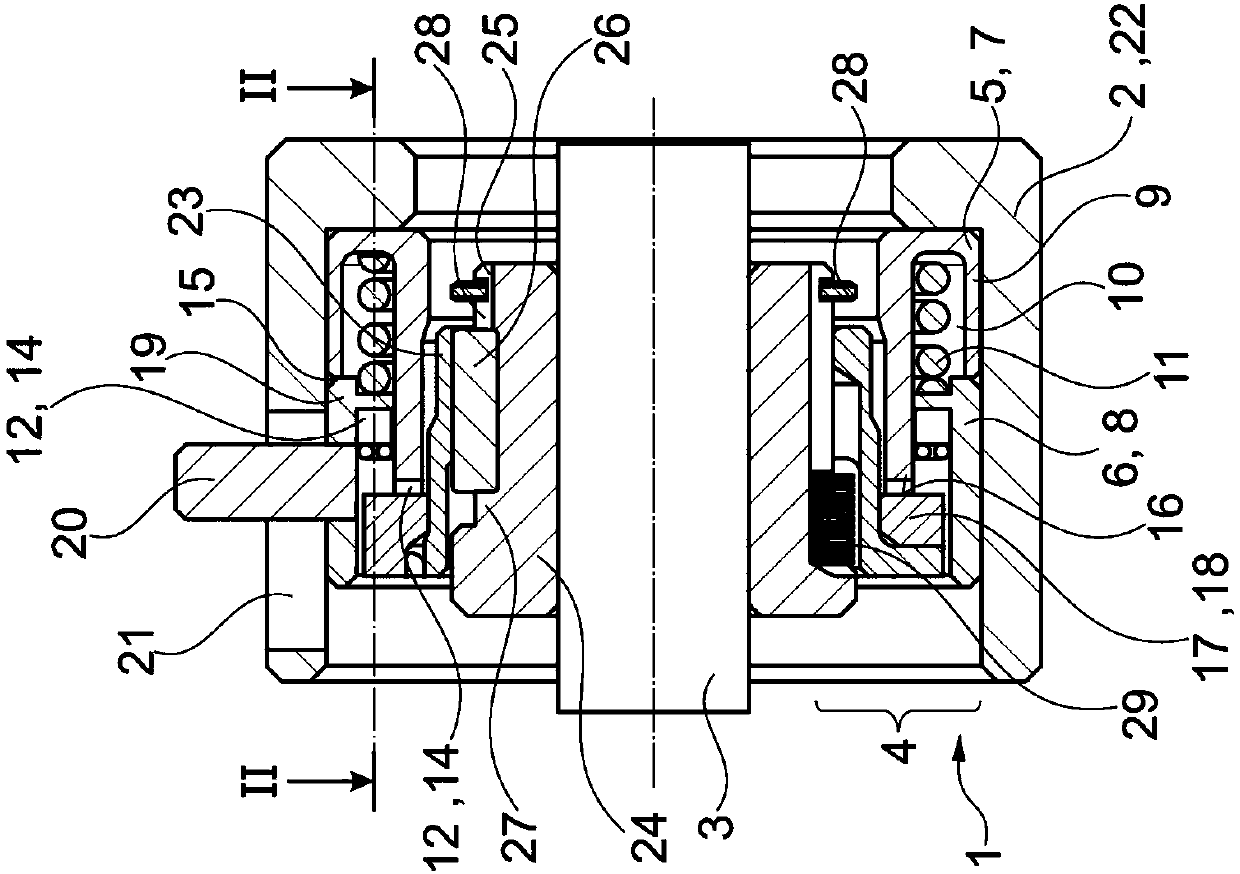

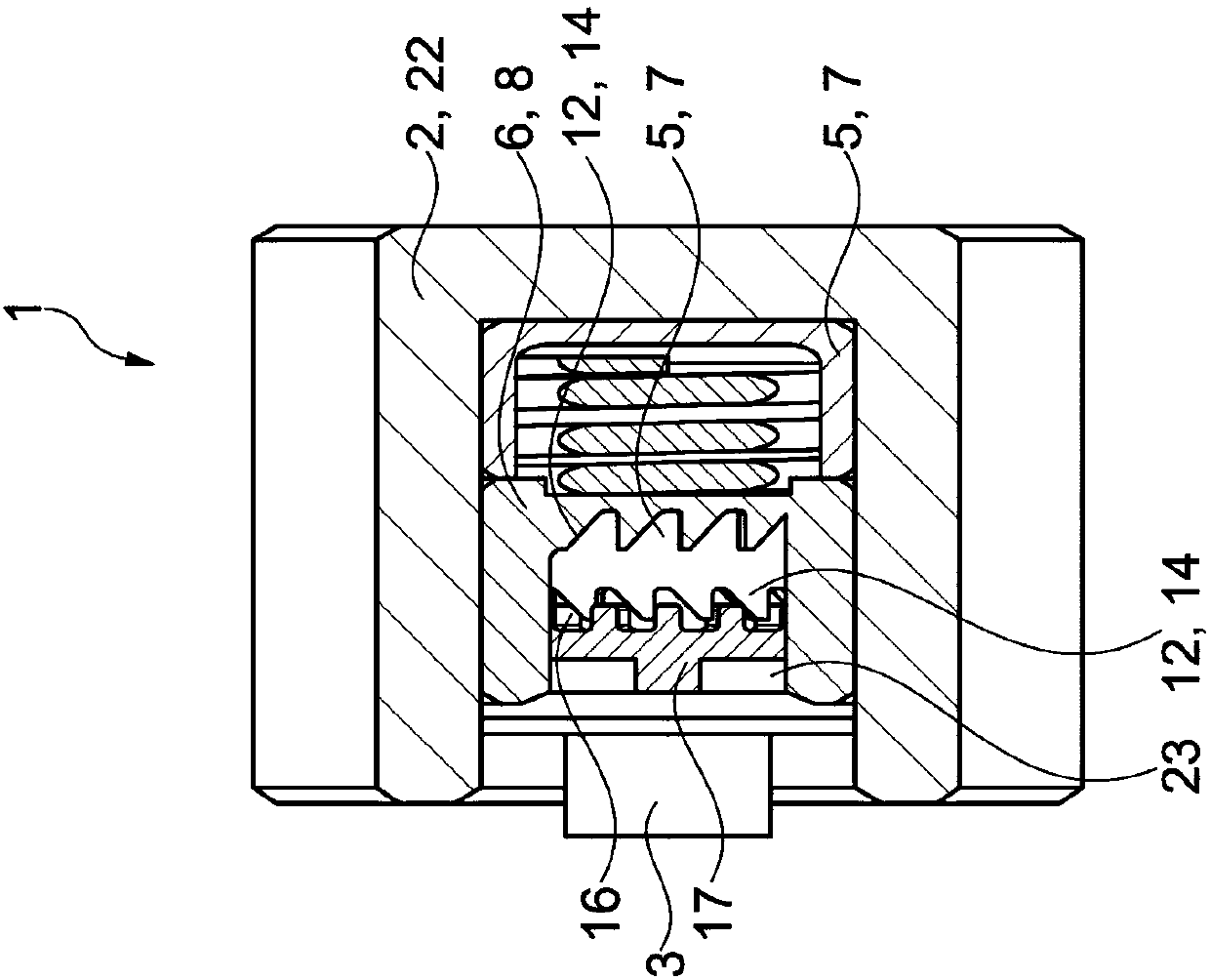

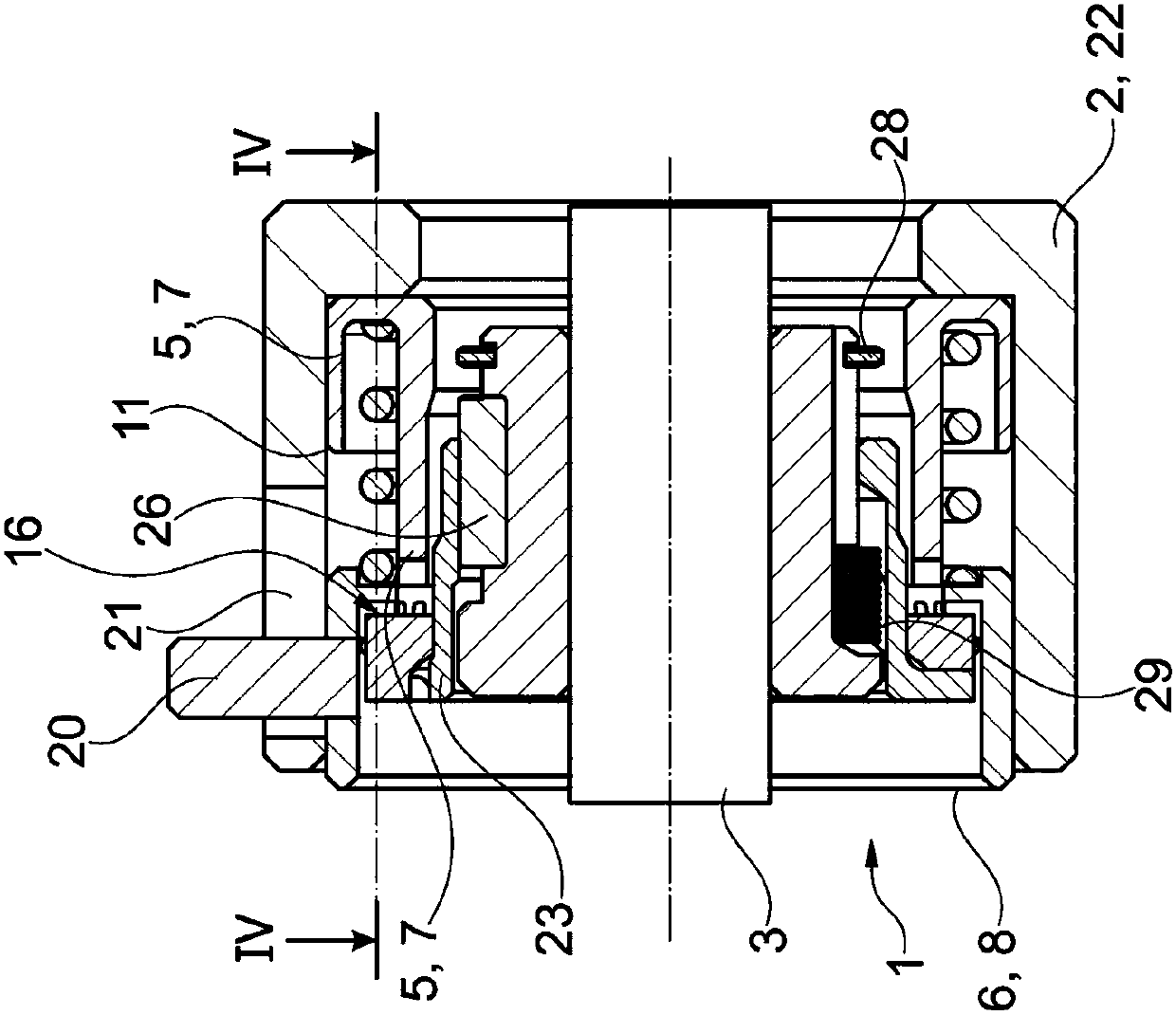

[0060] The drawings are only schematic and are used to aid understanding of the present invention. The same elements are denoted by the same reference numerals.

[0061] figure 1 A ratchet 1 according to the invention is shown. Said ratchet 1 , which can also be called ratchet or ratchet, is in switching position 1 in order to ensure right-hand rotation. It has a torque introducing or input element (input sleeve / ratchet housing) 2 and a torque releasing or output element (output sleeve / output shaft) 3 . A toothed unit (ratchet transmission) 4 is arranged between the two components 2 and 3 . Preferably, the toothed unit 4 can be switched manually. Depending on the switching position of the toothed unit 4 , torque is or can be transmitted from the torque vectoring element 2 to the torque release element 3 in the direction of rotation selected corresponding to the switching position. Depending on the switching position and the direction of rotation on the torque vectoring el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com