Junction box

A junction box and connector technology, which is applied in the field of junction boxes, can solve the problems of reducing the connection accuracy of the connector 32 and the socket 12, the main body 10 does not move up and down smoothly, and the assembly accuracy of components is reduced, etc. The effect of simplifying the coupling/decoupling structure and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

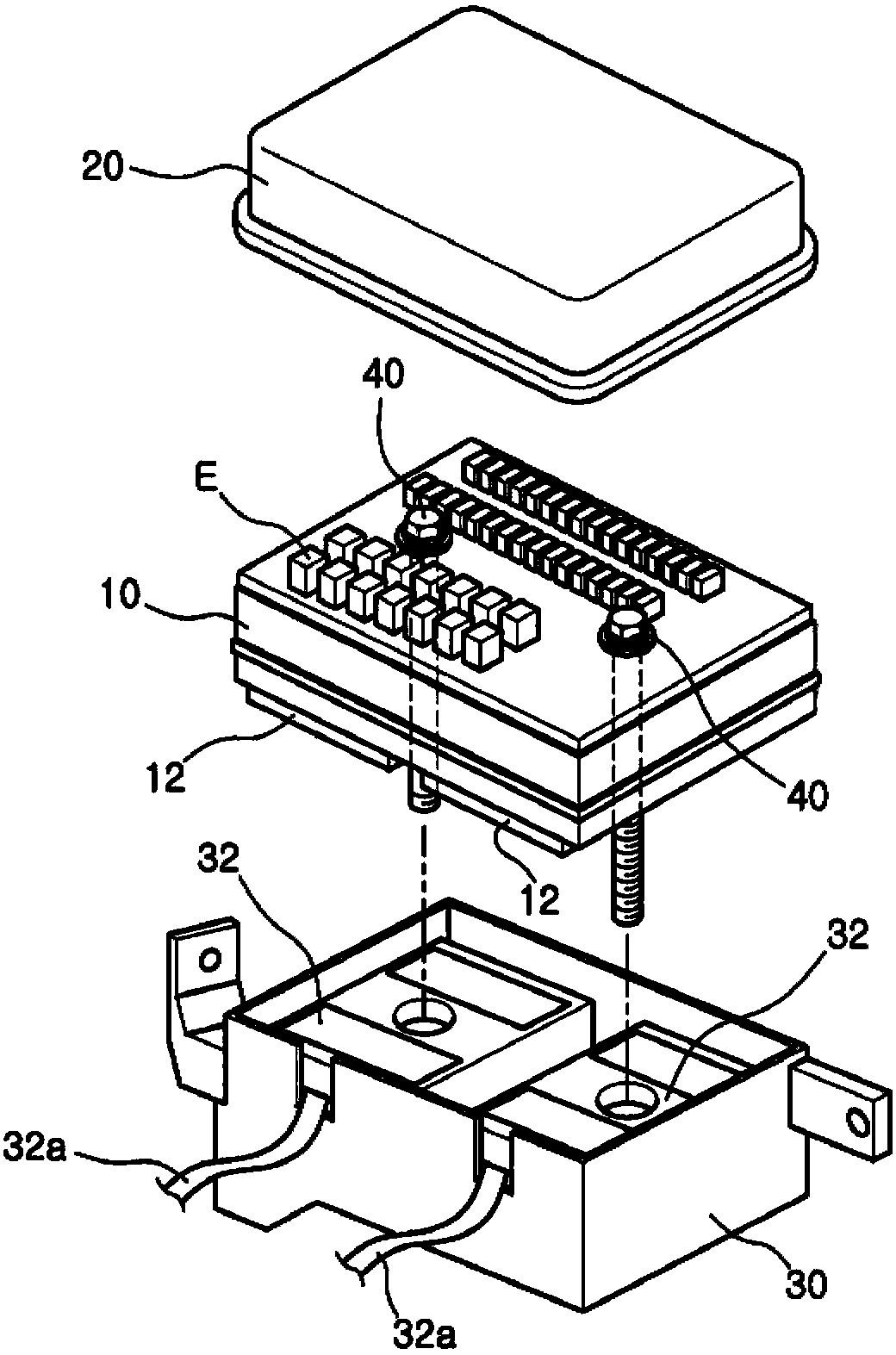

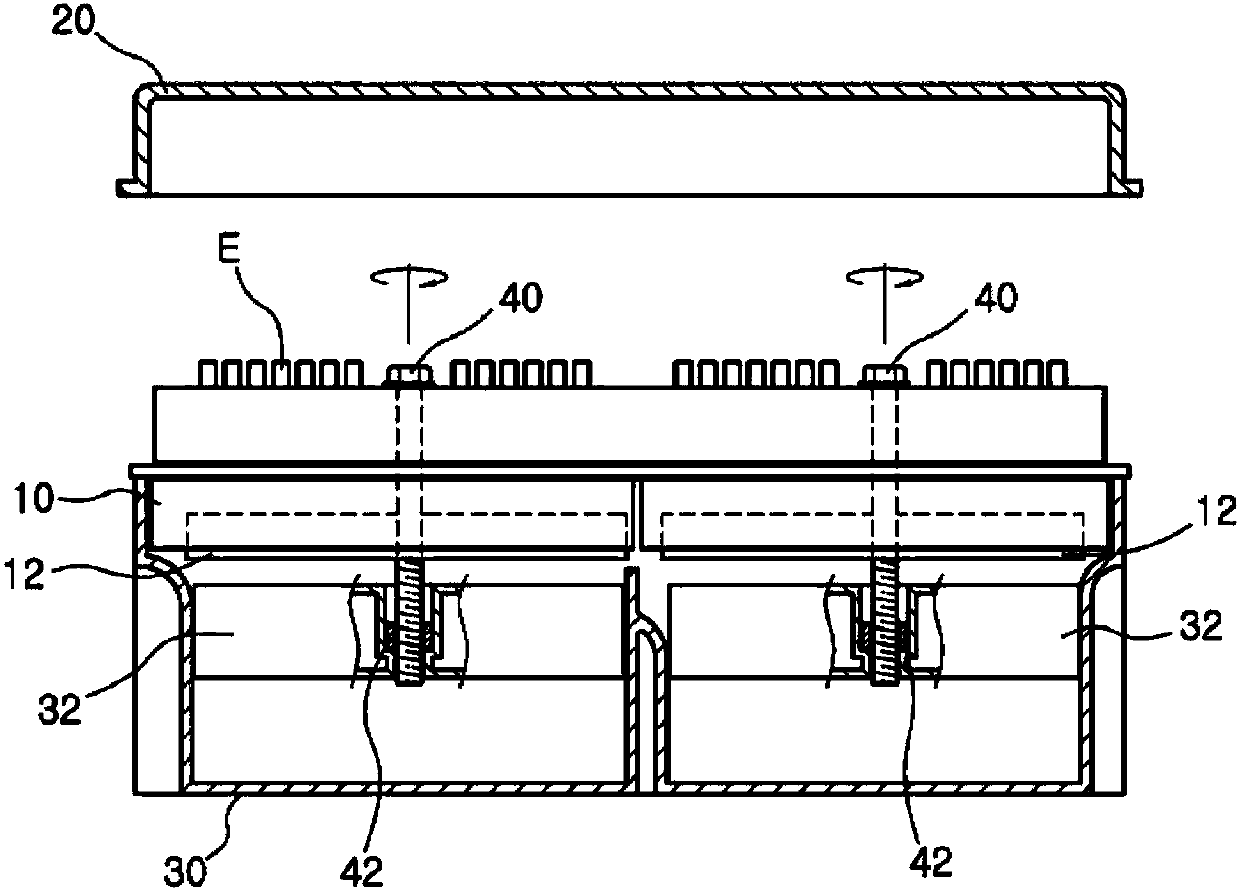

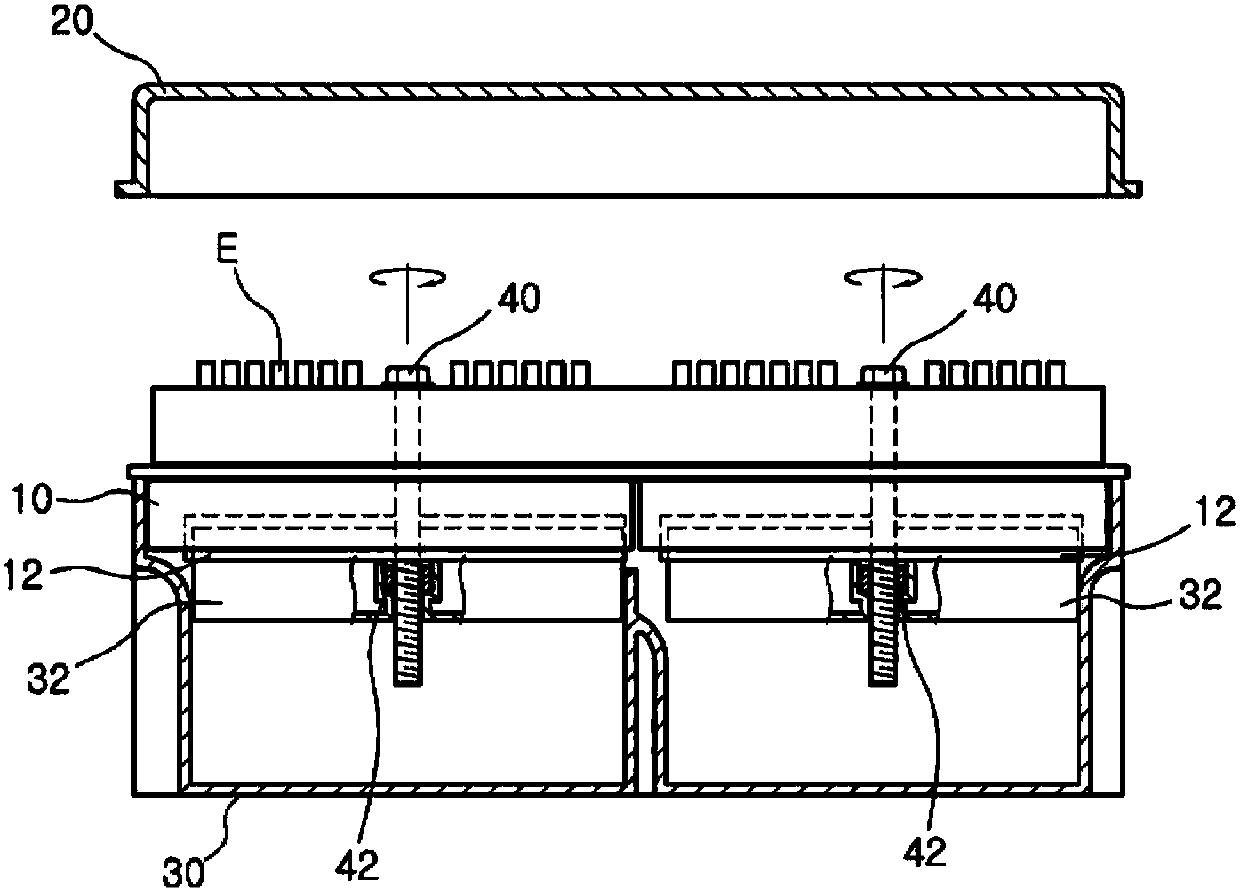

[0077] Preferred embodiments of a junction box according to the present invention will now be described in detail with reference to the accompanying drawings (parts identical to those of the previously described prior art example will be denoted by the same reference numerals).

[0078] Before describing the features of the junction box according to the present invention, the outline of the bonding wire will be briefly described.

[0079] The junction box includes a main body 10 in which a plurality of circuit parts E are mounted. The socket 12 is installed on the lower surface of the main body 10 , and the upper cover 20 is assembled to the upper surface of the main body 10 . The upper cover 20 covers the upper portion of the main body 10 to protect the circuit parts E of the main body 10 .

[0080] The junction box further includes a lower cover 30 covering a lower portion of the main body 10 . A connector 32 is installed in the lower cover 3 .

[0081] The connector 32 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com