Vacuum pressure sensor assembling device and assembling method thereof

A vacuum pressure and assembly equipment technology, which is applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems that vacuum pressure sensor assembly cannot be applied, and achieve the effect of reducing labor intensity, reducing manufacturing cost, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

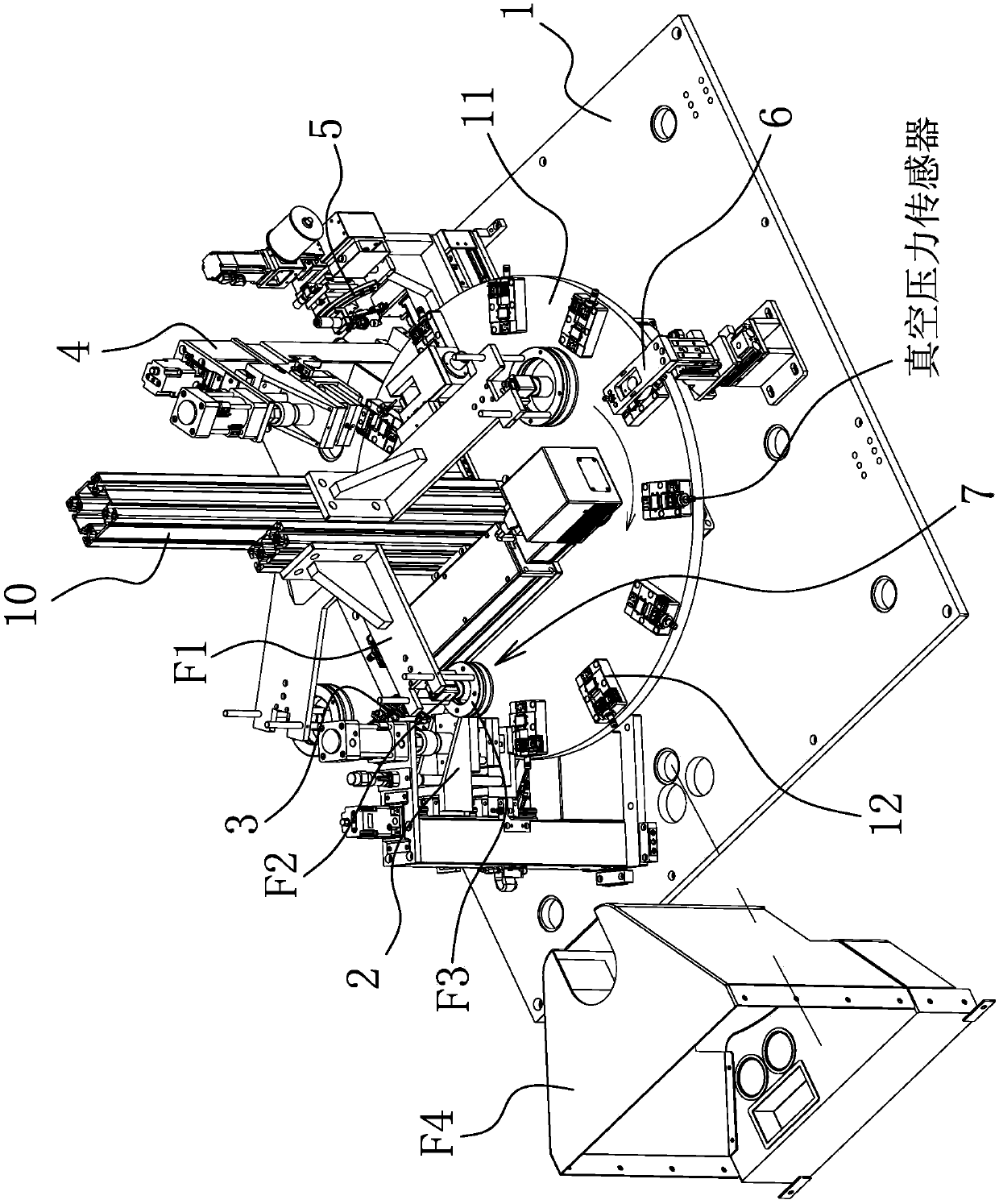

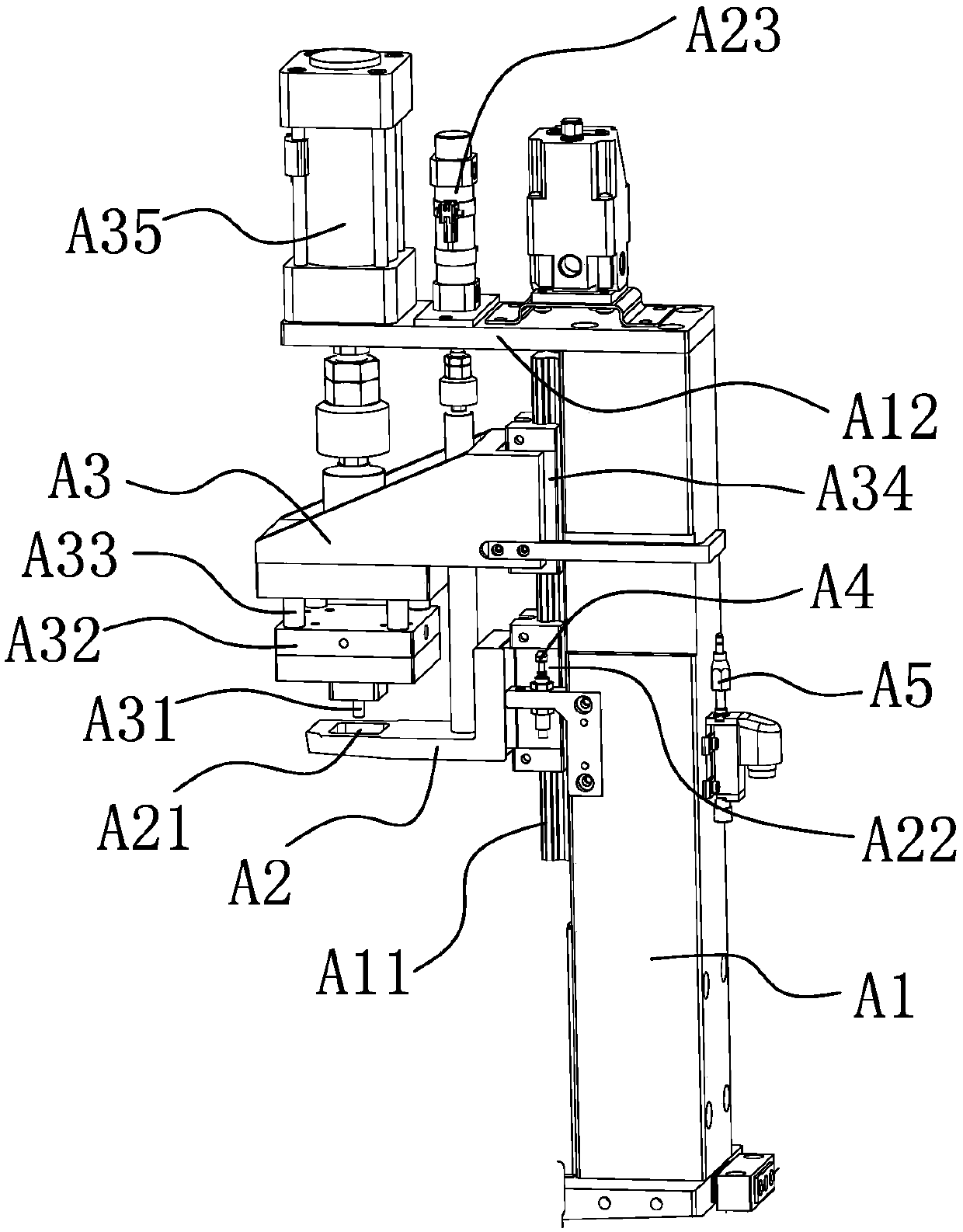

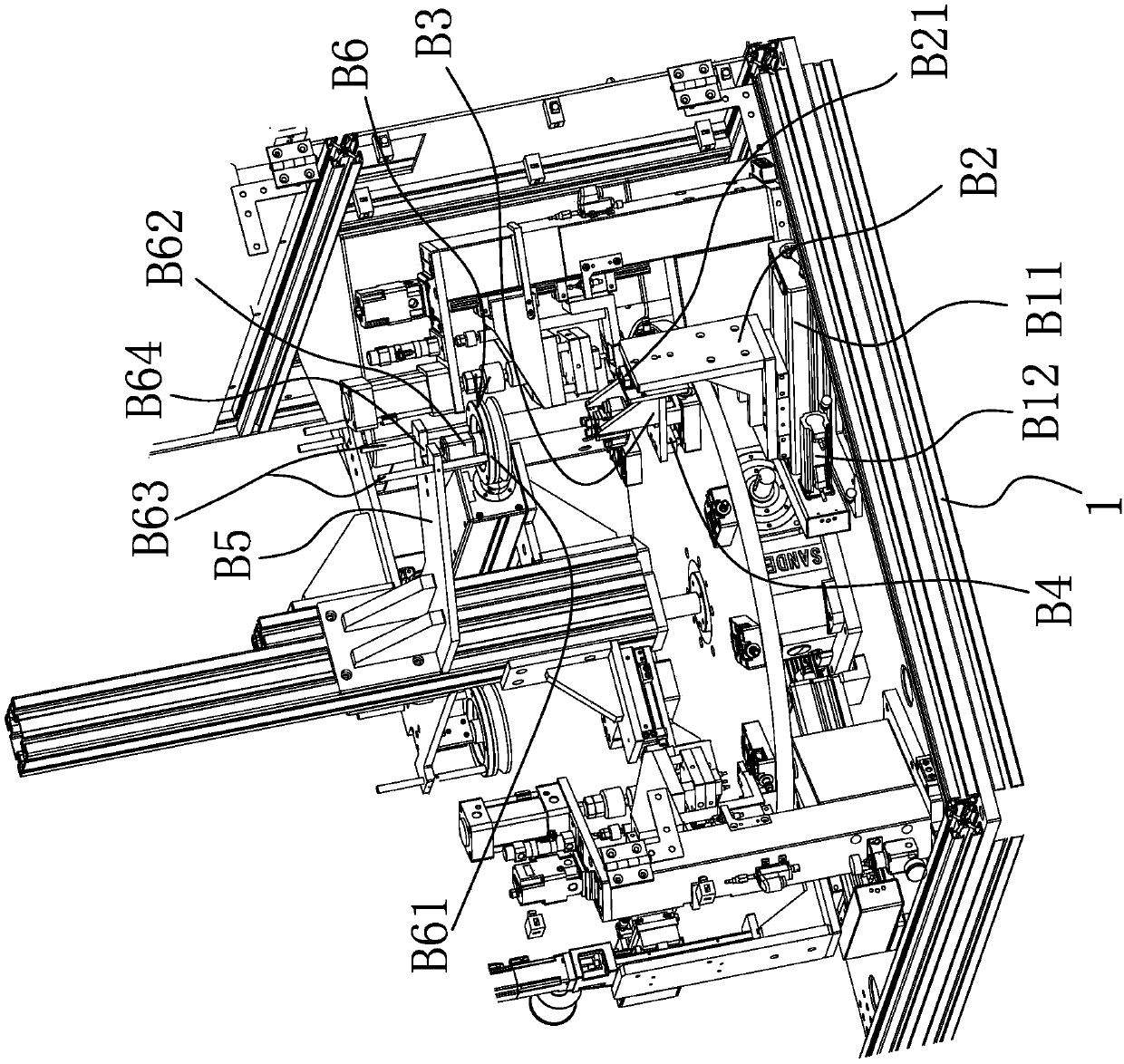

[0116] Such as figure 1 As shown, the vacuum pressure sensor assembly equipment includes a frame 1, a protective shell is provided on the frame 1, a turntable 11 is arranged on the frame 1, the turntable 11 is connected with a turntable drive mechanism, and the turntable drive mechanism includes a servo motor, a servo The motor is connected to the connecting shaft of the turntable through a belt transmission or gear transmission structure. On the turntable 11, there are several positioning fixtures 12 distributed around the circumference. Hot-melt positioning mechanism 2, circuit board pre-assembly mechanism 3, circuit board hot-melt positioning mechanism 4, automatic soldering mechanism 5 and cover plate positioning mechanism 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com