Spindle rails for ring spinning machines

A ring spinning machine, spindle rail technology, used in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., to achieve high yarn yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

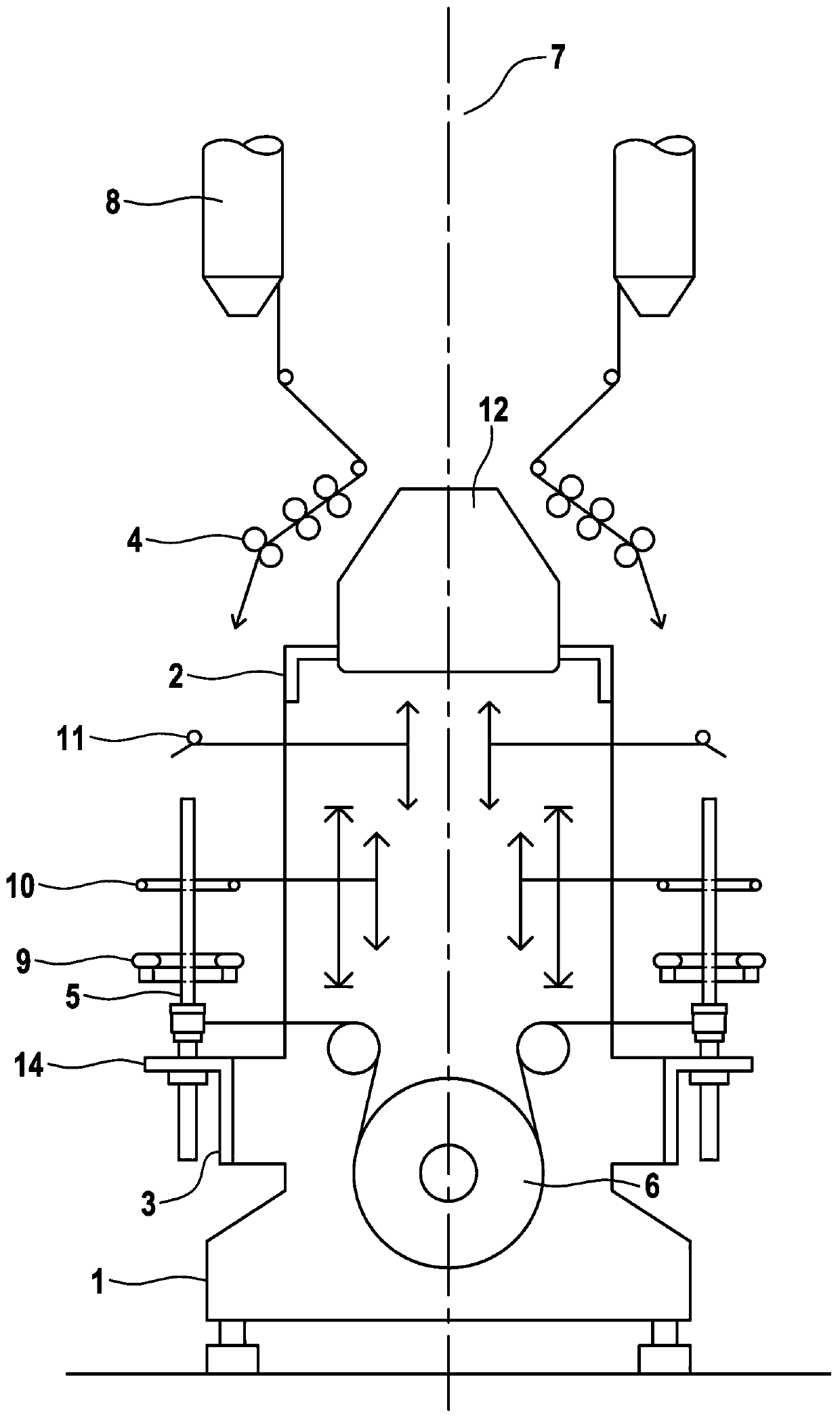

[0043] in figure 1 An example of a ring spinning machine with a unified structure that has been widely used and provided so far is shown in. The stable intermediate support 1 arranged transversely to the longitudinal axis of the ring spinning machine is equipped with longitudinal beams 2 and 3 for accommodating the drafting device 4 and the spindle 5. Between the drafting devices there is an air channel 12 for sucking away the broken yarn. Between the spindles 5 are a spindle drive mechanism 6 fixedly arranged on the machine and a fixed-position spindle rail 14, and above the drafting device is a creel 7 with a roving bobbin 8. The longitudinal beams for the spinning ring 9, the balloon ring 10 and the yarn guide 11 whose movement space is indicated only by the vertical double arrow are vertically movable.

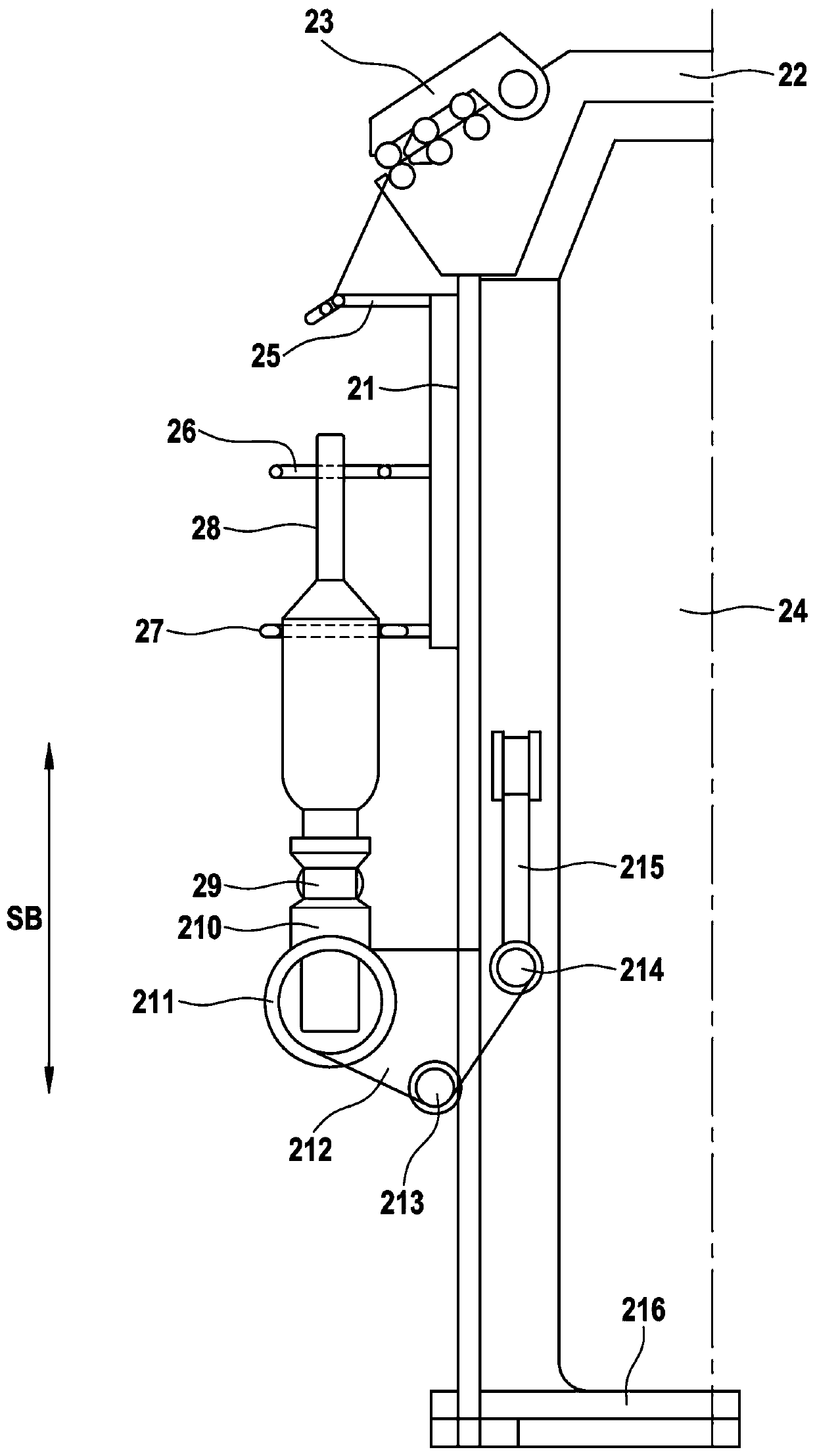

[0044] figure 2 Shows the left half of the ring spinning machine. One must understand that the centerline shown is a symmetrical whole machine. The yarn guide (pigtail y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com