Matching structure of rim outer frame and tire

A technology of matching structure and outer frame, applied in tire parts, tire rims, rims, etc., can solve problems such as broken rope joints, fixed rope stress concentration, and bead 11' split.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

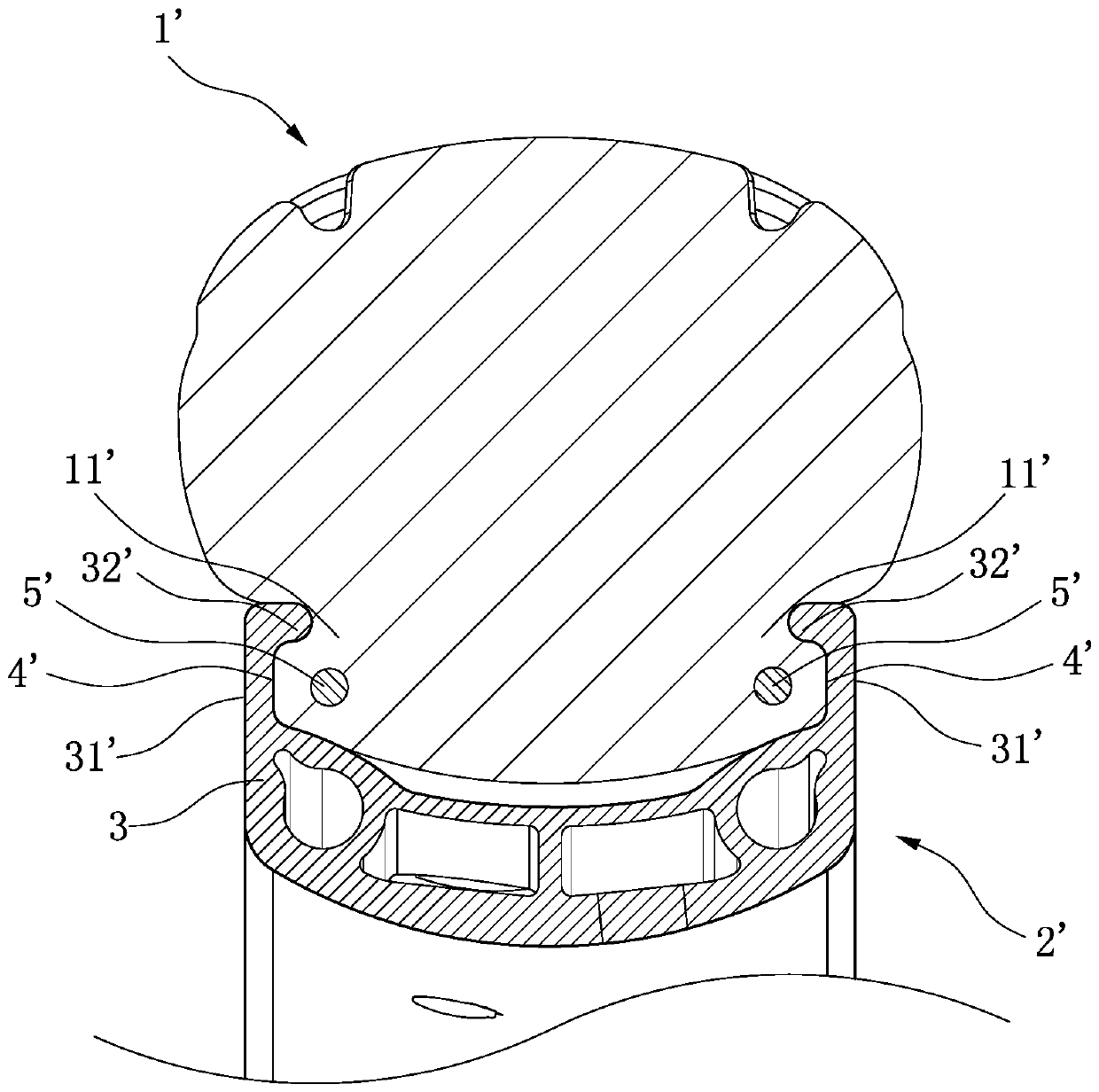

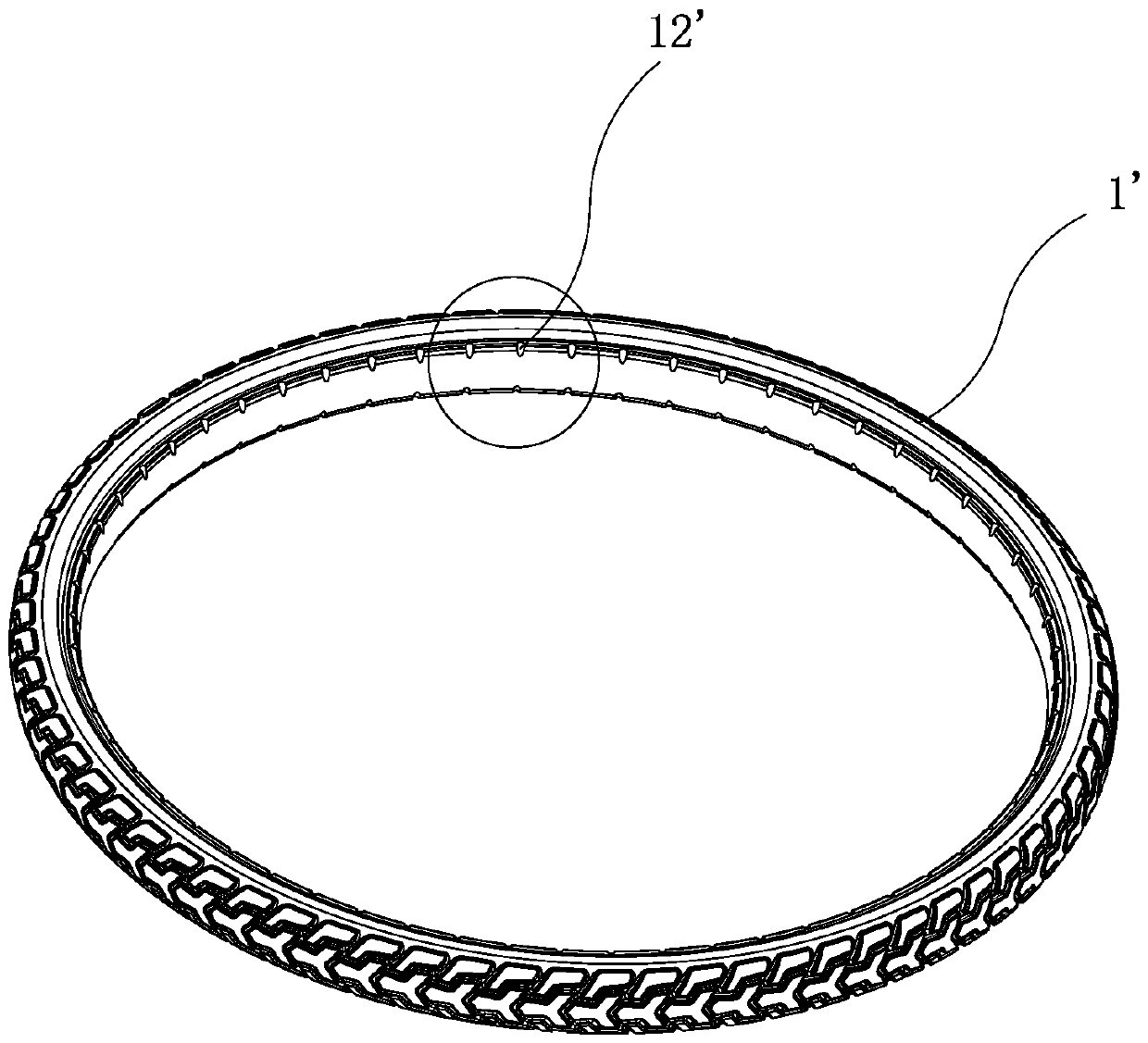

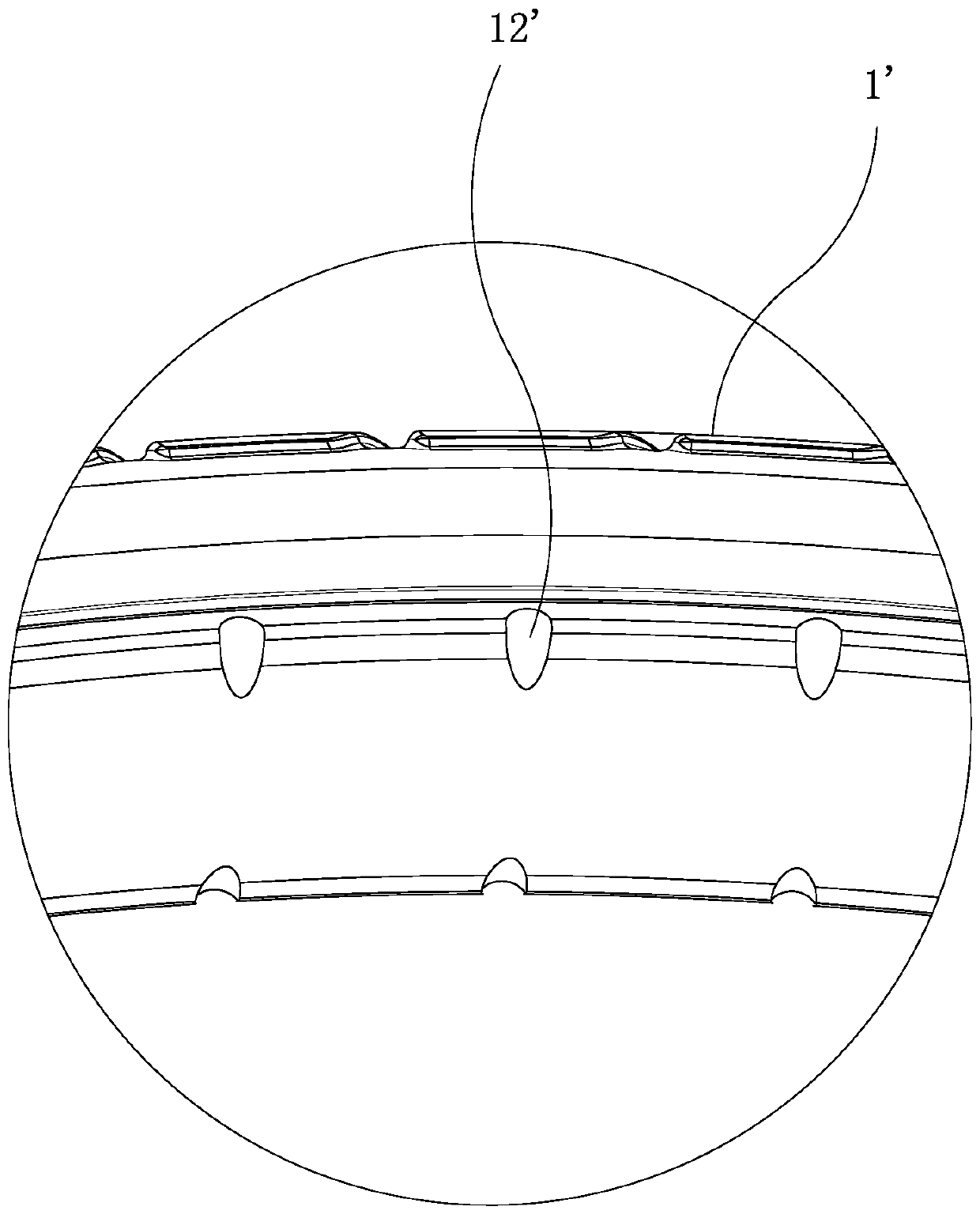

[0028] Such as Figure 5 As shown, the protruding portion 2 includes a first protruding portion 21 and a second protruding portion 22, the first protruding portion 21 and the second protruding portion 22 are distributed in a continuous ring around the inner wall of the rim outer frame 1, and The first protruding parts 21 and the second protruding parts 22 respectively located on the ring walls 11 on both sides are symmetrically distributed, and the first protruding parts 21 and the second protruding parts 22 are bent downward toward the inner direction of the rim to form an inverted The bead portion 31 of the tire 3 is provided with a groove 34 that cooperates with the protrusions 2 on the two sides of the ring wall 11, and the groove 34 is tightly fitted with the protrusion 2, thereby fixing the rim Box 1 and tire 3.

Embodiment 2

[0030] Such as Figure 6 As shown, the protruding portion 2a includes a first protruding portion 21a and a second protruding portion 22a, and the first protruding portion 21a and the second protruding portion 22a surround the inner wall of the rim outer frame 1 in a discontinuous annular distribution. There is at least one discontinuity 23a between the first protruding portion 21a and the second protruding portion 22a, and the first protruding portions 21a and the second protruding portions 22a respectively located on the ring walls 11 on both sides are symmetrically distributed. The first protruding portion 21a and the second protruding portion 22a are bent downward toward the inner direction of the rim to form an undercut. The mutually matched grooves 34a, said grooves 34a are closely fitted with the protrusions 2a, thereby fixing the rim outer frame 1 and the tire 3.

Embodiment 3

[0032] Such as Figure 7 As shown, the protruding portion 2b includes a first protruding portion 21b and a second protruding portion 22b, the first protruding portion 21b is distributed in a continuous ring around the inner wall of the rim outer frame 1, and the second protruding portion 22b Surrounding the inner wall of the rim outer frame 1 is a ring-shaped discontinuity 23b, the second protrusion 21b has at least one discontinuity 23b, and is respectively located on each first protrusion 21b and The second protrusions 22b are distributed symmetrically left and right respectively. The first protrusions 21b and the second protrusions 22b are bent downward toward the inside of the rim 1 to form an undercut. The bead portion 31 of the tire 3 is provided with The grooves 34 that cooperate with the protrusions 2 on the two side ring walls 11, the bead portion 31b of the tire 3b is provided with a groove 34b that cooperates with the protrusions 2b on the two side ring walls 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com