Automatic plate production device

An automatic production and plate technology, applied in unloading devices, devices for coating liquid on the surface, transportation and packaging, etc., can solve the problems of low application efficiency, easy spillage of coatings, and easy damage of coatings, etc., to achieve improved Efficiency, avoiding waste, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

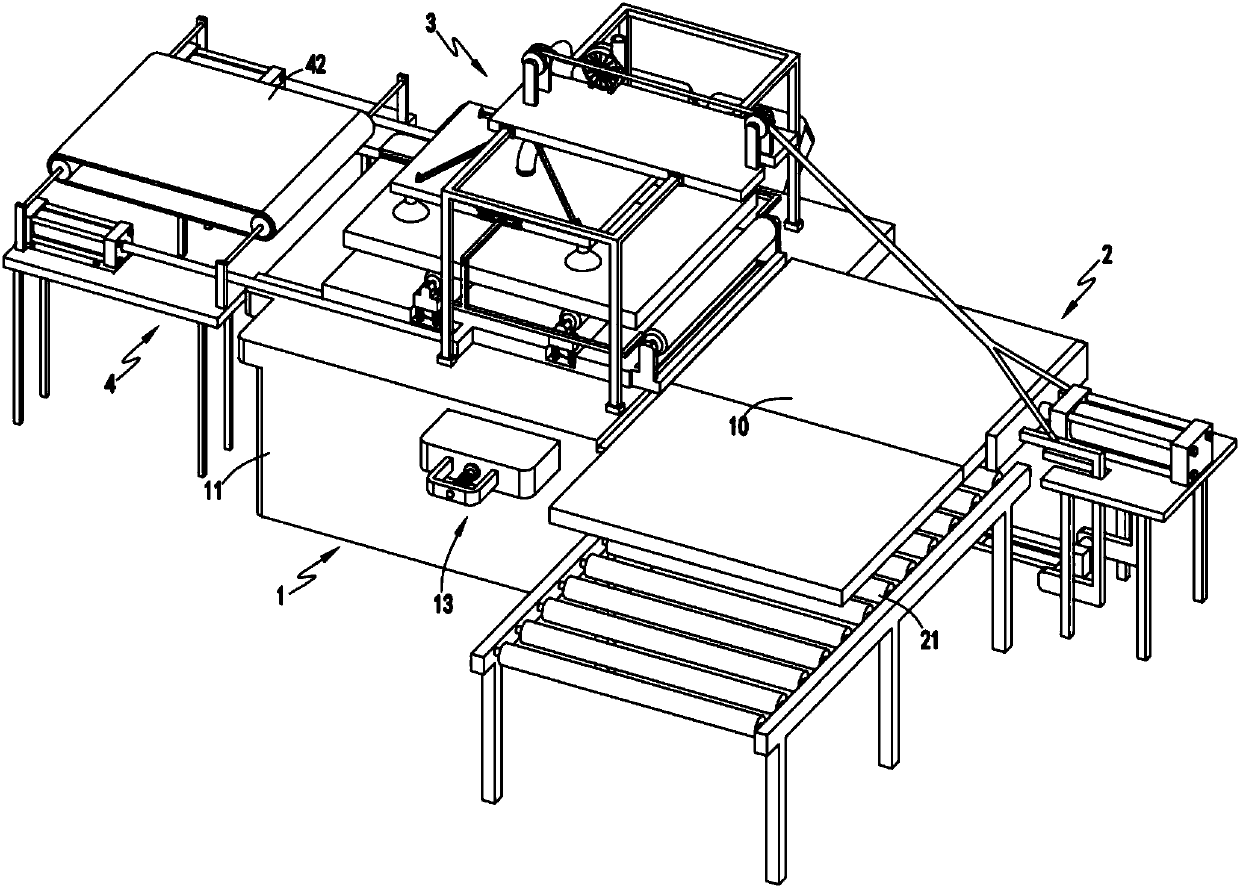

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, a kind of plate automatic production device comprises coating device 1, and described coating device 1 comprises material box 11, is arranged in the material box 11 and is used for extruding the coating material in material box 11 to make coating contact the lower surface of plate material 10 The extrusion mechanism 12 and the overflow mechanism 13 arranged on the side of the material box 11, the upper surface of the material box 11 is provided with an opening 14, and the opening 14 is provided with a cover plate 15;

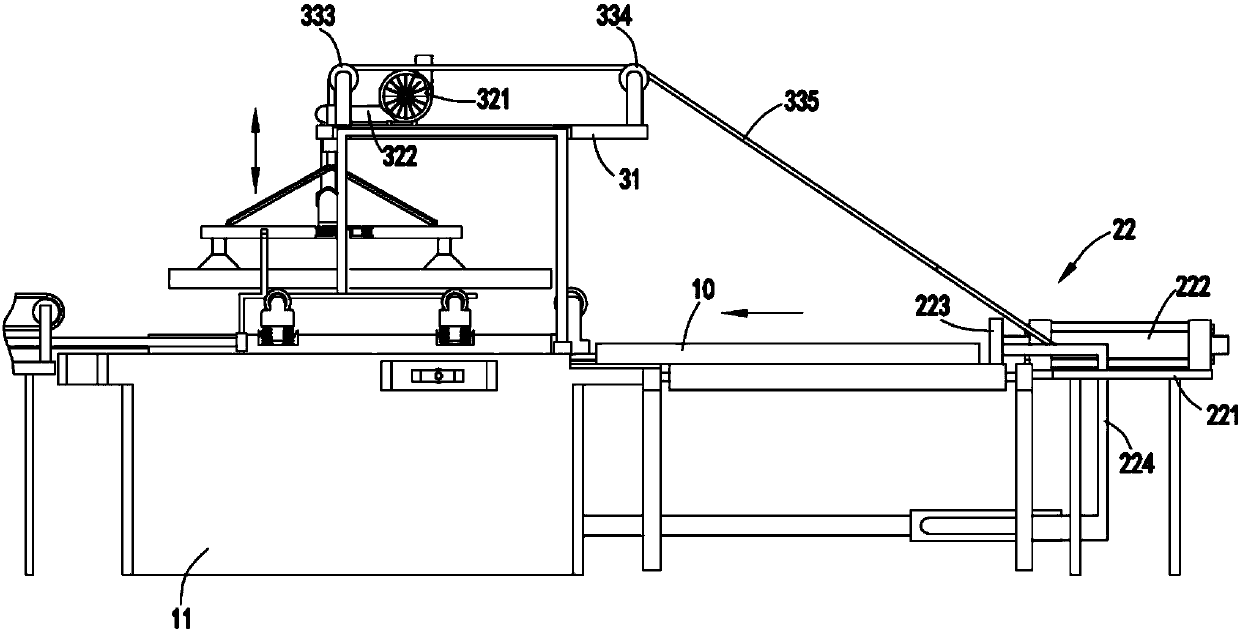

[0046] The feeding device 2, the feeding device 2 is arranged at the front end of the material box 11, the feeding device 2 includes a feeding roller set 21 and a pushing mechanism 22, and the pushing mechanism 22 is used to push the plate 10 along the upper end of the opening 14 Push the cover plate 15 away fro...

Embodiment approach

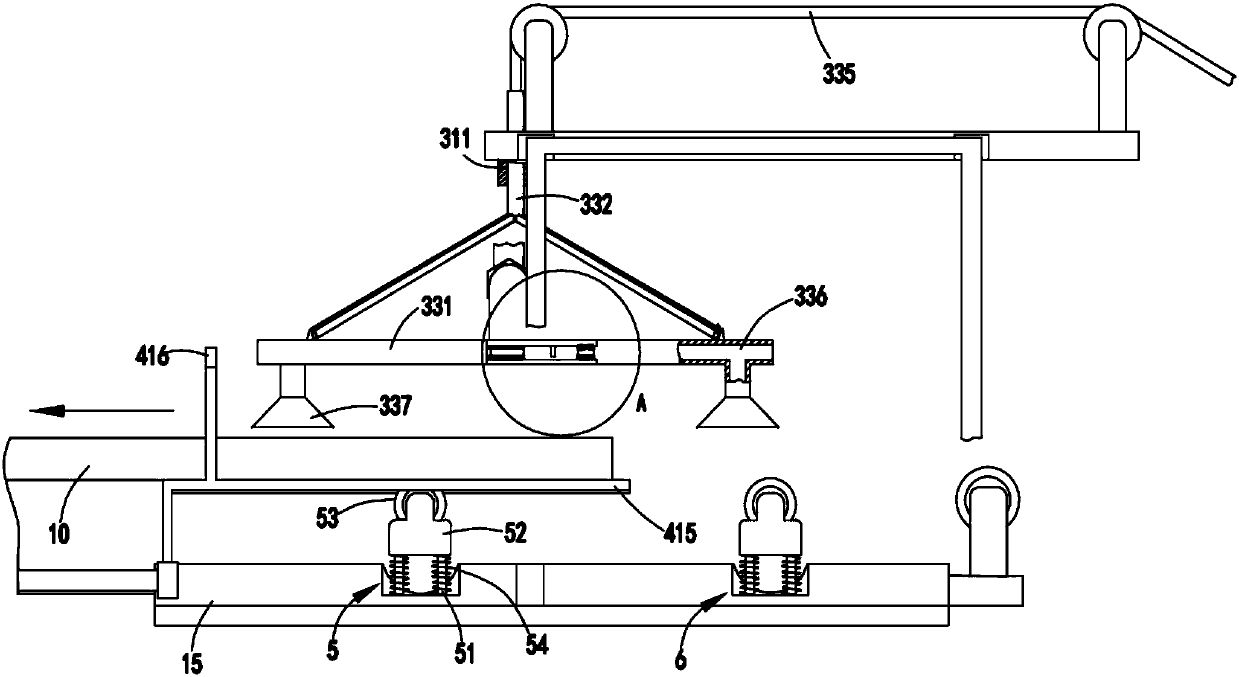

[0054] Further, as image 3 with Figure 4 As shown, as yet another preferred embodiment, the suction mechanism 32 includes a suction machine 321 and a hose 322 whose end communicates with the suction port of the suction machine 321;

[0055] The suction mechanism 33 includes a suction disc 331, a guide rod 332 fixedly connected at one end to the center of the suction disc 331, a first pulley 333 and a second pulley 334 arranged on the bracket 31, and a first pulley 333 and a second Pulley 334 and the traction rope 335 that one end is fixedly connected with the other end of guide bar 332, and the other end of described traction rope 335 is fixedly connected with connecting frame 224;

[0056] A cavity 336 is provided inside the suction plate 331, and the other end of the flexible tube 322 is fixedly connected to the suction plate 331 and communicated with the cavity 336. There are a number of cavities connected to the four corners of the bottom surface of the suction plate 33...

Embodiment 2

[0067] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is: further, the overflow mechanism 13 includes an overflow box 131, an overflow block 132 that slides with the inner wall of the overflow box 131, and is arranged on the overflow The support member 133 on one side of the box body 131 and the guide rod 136 that slides with the guide hole a134 provided on the side of the overflow tank body 131 and the guide hole b135 provided on the support member 133, one end of the guide rod 136 and The overflow block 132 is fixedly connected, the guide rod 136 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com