Front edge plate lifting device

A frontier board and pedal technology, applied in the field of elevators, can solve problems such as screw loss, screw hole wear, insufficient lifting force, etc., to achieve the effect of avoiding loss, improving reliability and safety, and improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

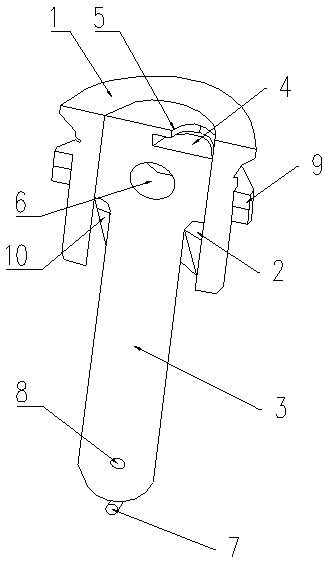

[0013] A leading edge plate lifting device related to the present invention has a pedal bushing 1, a chute 2 and a handle 3 arranged concentrically, wherein the chute 2 is set in the pedal bushing 1, and the handle 3 is connected in the chute 2. The chute 2 is also provided with an installation clamp 10 for limiting the handle 3, the diameter of the handle 3 on the upper side of the limit clamp 10 is greater than the diameter of the handle 3 on the lower side of the limit clamp 10, and the handle 3 The top of the top is provided with a lifting hole 4 and a lifting edge 2 arranged on the inner side of the lifting hole 4, and a lifting hole 6 passing through the handle 3 is provided under the lifting hole 4. The circlip mounting hole 8 of the circlip 7 is installed, and an external thread 11 is arranged on the outside of the pedal casing 1 , and a mounting nut 9 is sleeved on the external thread 11 .

[0014] In the specific use process, by inserting a tool such as a zipper into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com