Fischer-Tropsch slurry bed reaction system and Fischer-Tropsch synthesis reaction method

A reaction system, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of catalyst overheating, deposition, catalyst deactivation, etc. The effect of heat exchange efficiency and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

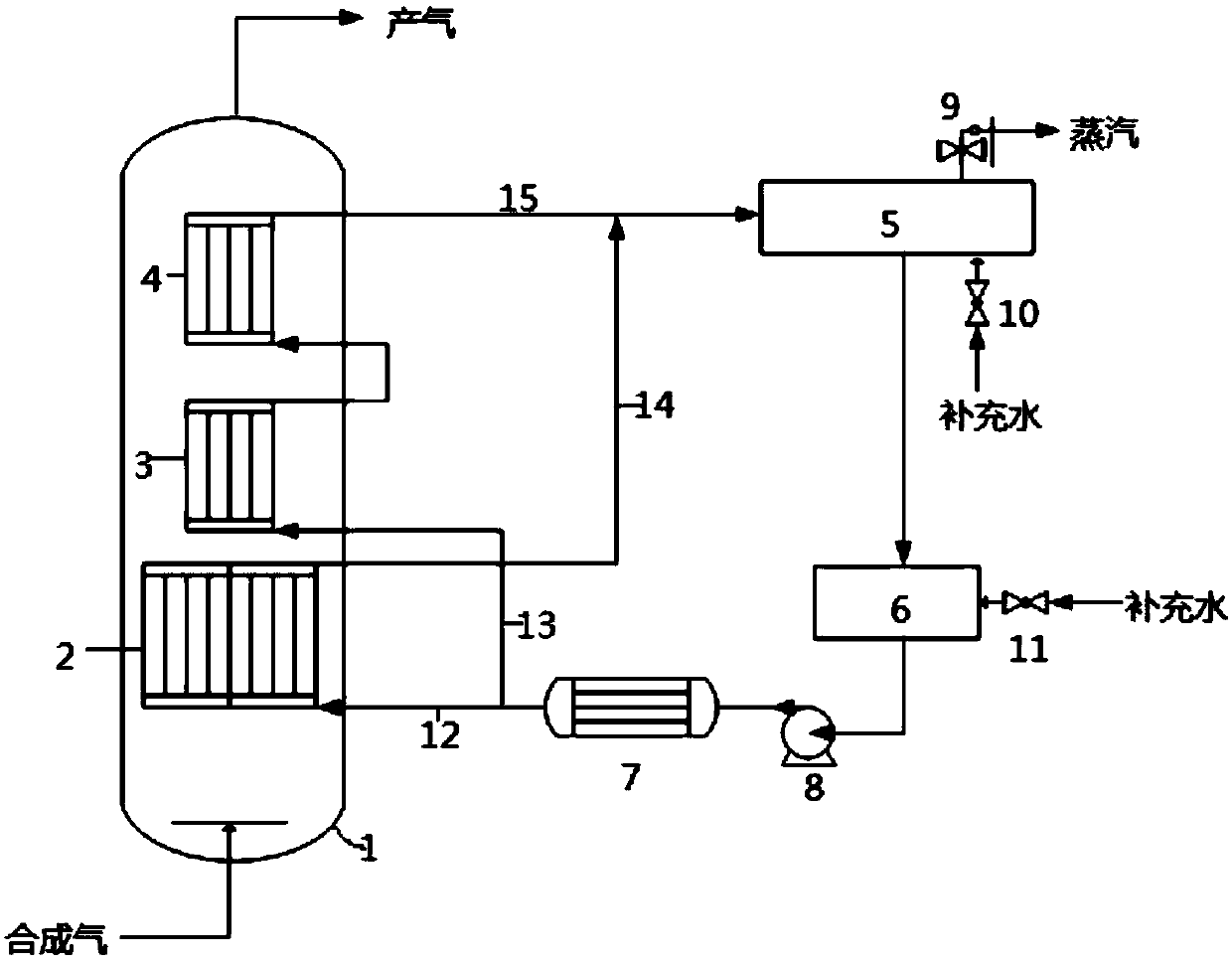

[0055] This example is used to illustrate the Fischer-Tropsch slurry bed reaction system and the Fischer-Tropsch synthesis reaction method of the present invention.

[0056] use figure 1 In the Fischer-Tropsch slurry bed reaction system shown, the syngas is introduced from the lower part of the slurry bed reactor 1, and the heater 7 is set so that the temperature rise rate of the flowing water is 20°C / h; When the temperature in 1 reaches 120°C, set the heater 7 so that the temperature rise rate of the water flowing through is 10°C / h; when the temperature in the slurry bed reactor 1 reaches 200°C, set the heater 7 so that the flow rate The heating rate is 5°C / h; when the temperature in the slurry bed reactor 1 reaches 250°C, it is deemed to have reached the specified reaction temperature of the Fischer-Tropsch synthesis reaction, and the heater 7 is turned off to stop heating; wherein, the steam drum 5 is set The threshold value of the pressure control valve 9 is 4MPa; the sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com