Semi-automatic mechanical locking mechanism

A mechanical locking and semi-automatic technology, applied in elevators, transportation and packaging, etc., can solve the problems of failure of safety devices, inability to reflect the full protection effect of safety mechanisms, complex structure, etc., and achieve simple structure, low production cost, and safety. high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

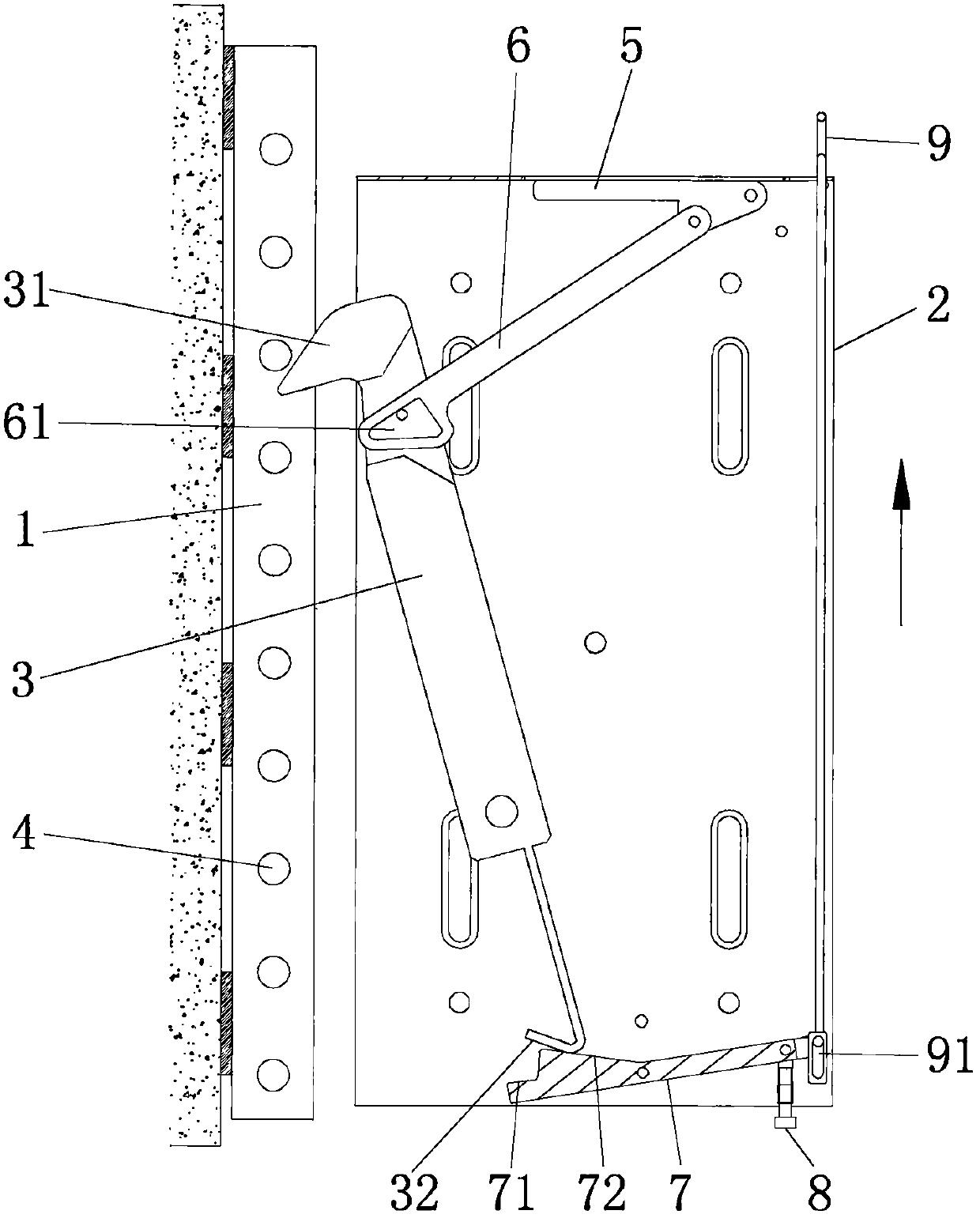

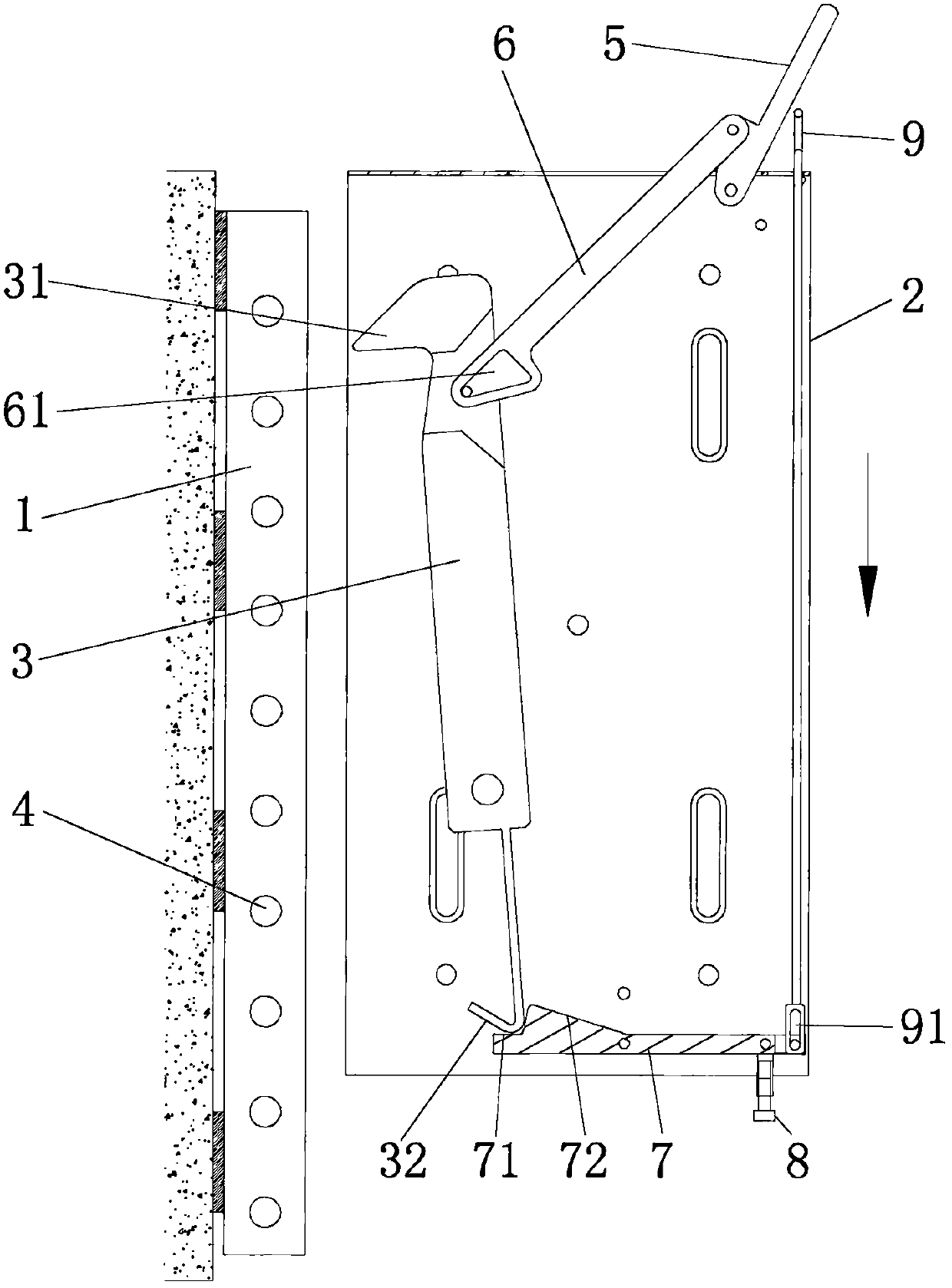

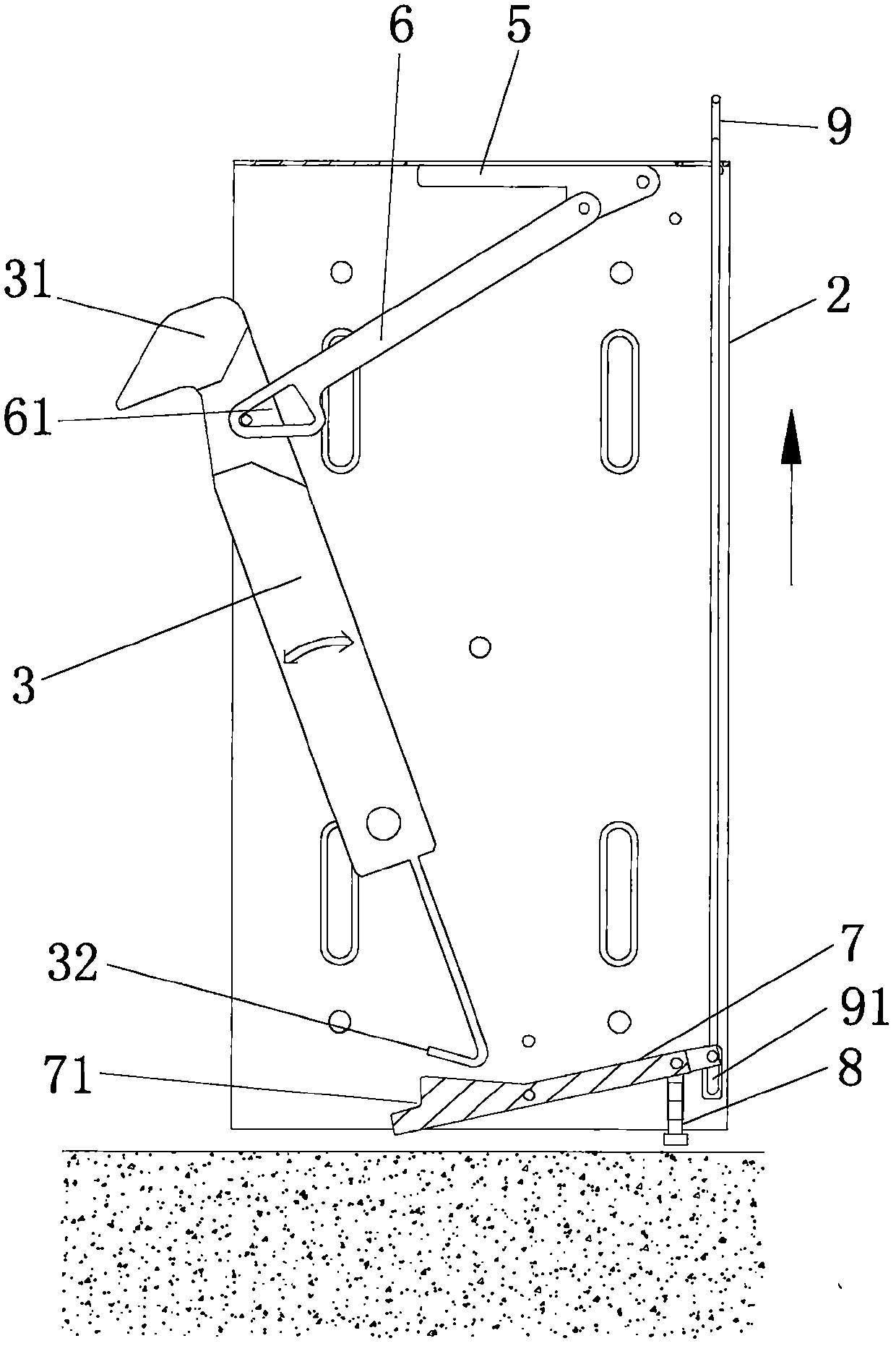

[0016] as attached Figures 1 to 3 The shown semi-automatic mechanical locking mechanism includes a guide rail 1 and a lift table 2 slidably mounted on the guide rail 1. The lift table 2 is hinged with a lock hook 3, and the guide rail 1 is provided with a lock bar corresponding to the lock hook 3. 4. One end of the lock hook 3 is provided with a hook portion 31 which can protrude from the lifting platform 2 to hook on the lock bar 4 . Under the control of the operator, the lock hook 3 can extend out of the lift table 2 to hook on the lock bar 4 , and of course it can also be completely retracted into the lift table 2 without contacting the lock bar 4 . The lock bar 4 is a cylinder, the hook portion 31 is in the shape of a sharp angle, and an acute angle is formed between one side of the hook and the body of the lock hook 3 for hooking the lock bar 4, and the other side is an inclined surface, When the lifting platform 2 is raised, the locking bar 4 of the cylinder can automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com