Dairy product and preparation method thereof

A dairy product and demulsification technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of room temperature yogurt that need to be improved, and achieve the effect of good quality uniformity and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

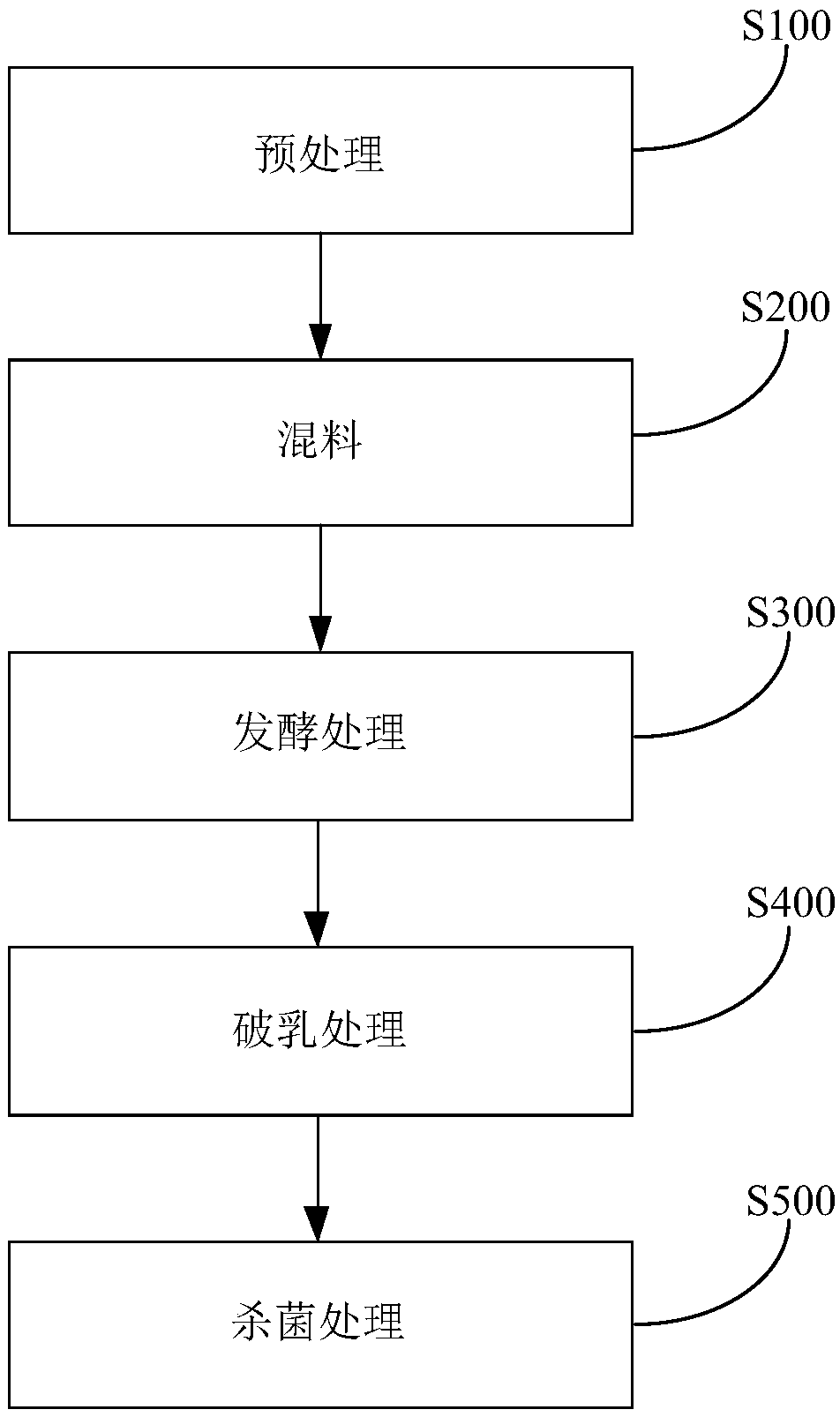

Method used

Image

Examples

Embodiment 1

[0088] 1. Raw materials of non-bacterial fermented drinking yogurt (based on 1000kg product):

[0089]

[0090]

[0091] 2. Production process of non-bacterial fermented drinking yoghurt

[0092] (1) Raw milk reception and index determination

[0093] After the raw milk is received, it is filtered through a filter with a pore size of 0.5 mm, and various indicators are measured, and the protein content is 3.49. The protein content reaches the standard, and the next step of process operation can be carried out.

[0094] (2) Sterilization and homogenization of raw milk

[0095] After the raw milk is preheated and degassed, it is homogenized under a total pressure of 160-180bar, and sterilized at 95±1°C for 300s to ensure that the raw milk before fermentation is in a sterile state, and cooled to 4°C for use.

[0096] (3) Mixing

[0097] Slowly raise the temperature of the milk to 45-50°C, then weigh the three stabilizers required for the system—pectin, agar, hydroxypropyl...

Embodiment 2

[0110] 1. Raw materials of high-protein non-bacterial fermented drinking yogurt (based on 1000kg product)

[0111]

[0112] 2. Production process of high-protein non-bacterial fermented drinking yoghurt

[0113] (1) Raw milk reception and index determination

[0114] After the raw milk is received, it is filtered through a filter with a pore size of 0.5mm, and various indicators are measured, and the protein content is 3.43, which reaches the standard, and the next step of process operation can be carried out.

[0115] (2) Sterilization and homogenization of raw milk

[0116] After the raw milk is preheated and degassed, it is homogenized under a total pressure of 160-180bar, and sterilized at 95±1°C for 300s to ensure that the raw milk before fermentation is in a sterile state, and cooled to 4°C for use.

[0117] (3) Dissolution of casein micelles

[0118] Dissolve 50kg of casein micelles in 500kg of pure water, the dissolution temperature is 55-60°C, the dissolution time...

Embodiment 3

[0133] 1. Raw materials of low-protein non-bacterial fermented yoghurt beverage (based on 1000kg product)

[0134]

[0135] 2. Production process of low-protein non-bacterial fermented yoghurt drink

[0136] (1) Raw milk reception and index determination

[0137] After the raw milk is received, it is filtered through a filter with a pore size of 0.5 mm, and various indicators are measured, and the protein content is 3.38. The protein content reaches the standard, and the next step of process operation can be carried out.

[0138] (2) Sterilization and homogenization of raw milk

[0139] After the raw milk is preheated and degassed, it is homogenized under a total pressure of 160-180bar, and sterilized at 95±1°C for 300s to ensure that the raw milk before fermentation is in a sterile state, and cooled to 4°C for use.

[0140] (3) fermentation

[0141] The starter is glucuronolactone, the dosage is 5kg / 1000kg product, the fermentation temperature is 43±1°C, and the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com