A high temperature compound regenerative adiabatic compressed air energy storage system

A compressed air energy storage, high temperature technology, applied in the field of compressed air energy storage, to achieve high heat recovery efficiency, reduce costs, and reduce the effect of heat storage temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

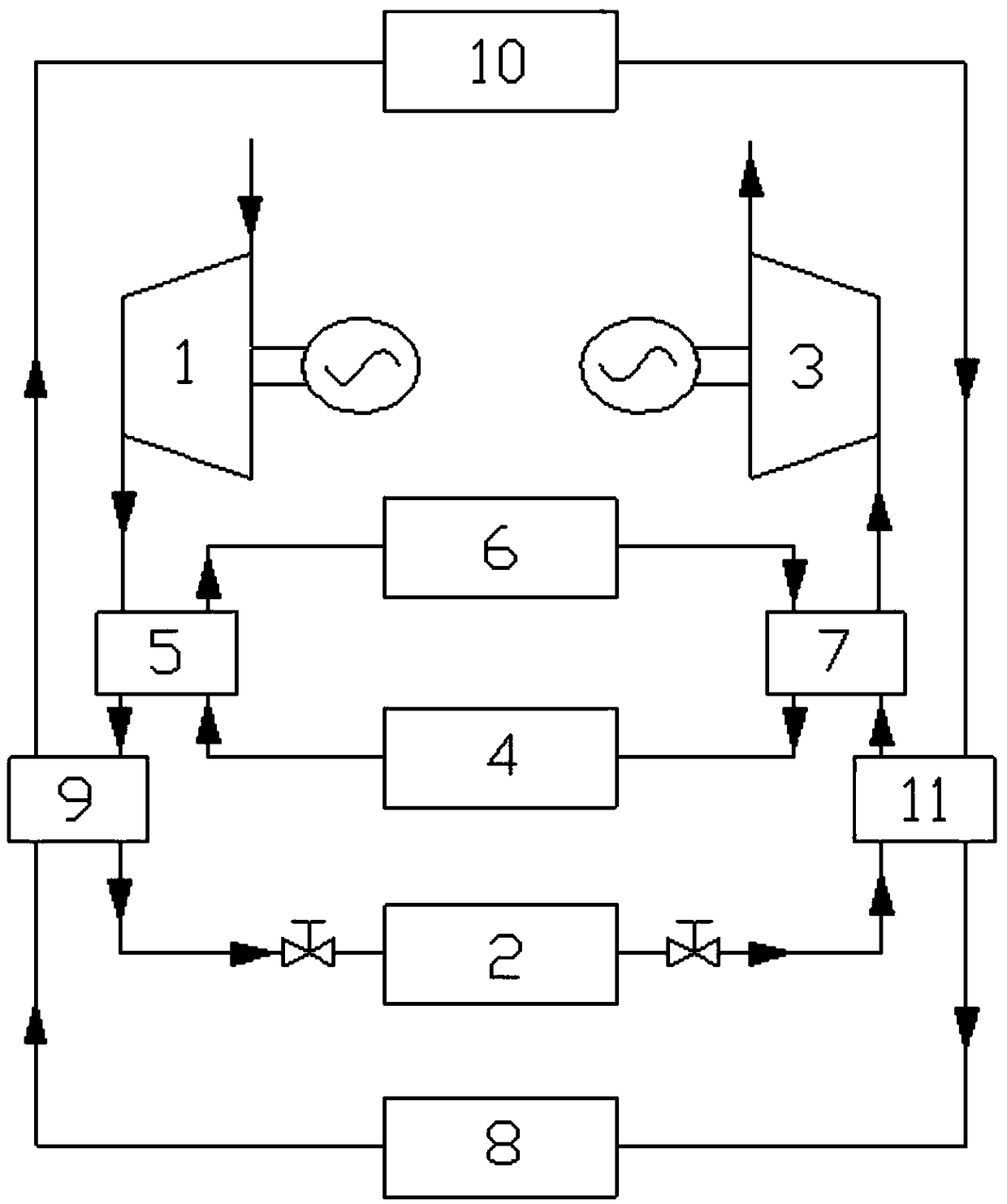

[0026] Such as figure 1 As shown, a single-stage compression, single-stage expansion high-temperature compound regenerative adiabatic compressed air energy storage system provided in this embodiment includes a high-temperature compressor unit 1, a gas storage chamber 2, a turbine generator unit 3, and a high-temperature regenerative cycle and medium temperature reheat cycle.

[0027] The high-temperature regenerative cycle includes a high-temperature cooler 5 , a high-temperature regenerator 6 , a high-temperature regenerator 7 and a high-temperature regenerator 4 . The heat exchange tube of the high-temperature cooler 5, the high-temperature regenerator 6, the heat-return tube of the high-temperature regenerator 7 and the high-temperature regenerator 4 are circularly connected;

[0028] The medium-temperature heat recovery cycle includes a medium-temperature cooler 9, a medium-temperature regenerator 10, a medium-temperature regenerator 11, and a medium-temperature regenerat...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

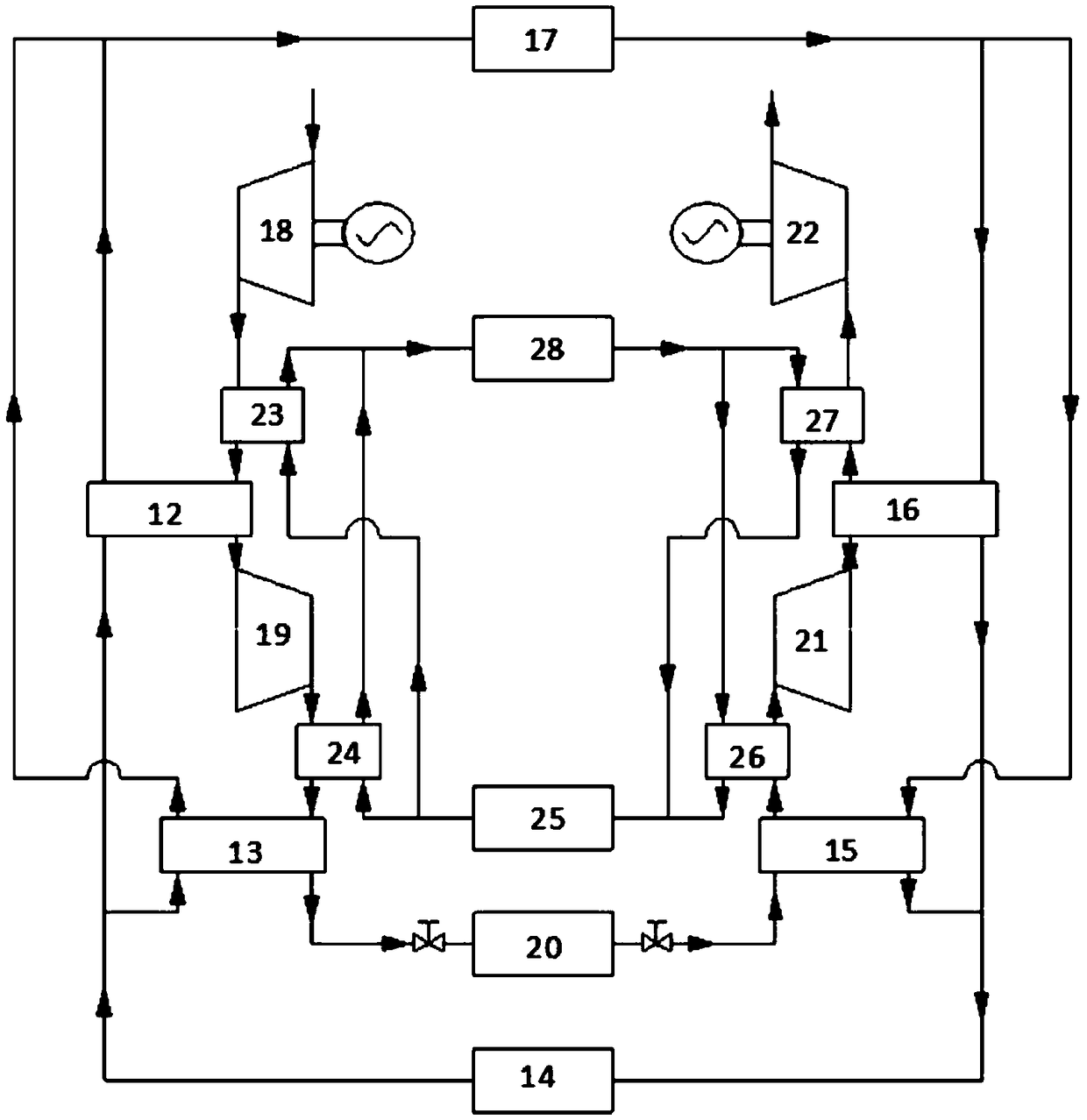

[0044] Such as figure 2 As shown, it is a dual-stage compression, dual-expansion high-temperature compound regenerative adiabatic compressed air energy storage system provided in this embodiment. Among them, the high-temperature compressor unit includes a multistage air compressor; the turbogenerator unit includes a multistage turboexpander and a generator.

[0045] In this embodiment, the high temperature compressor set includes a primary air compressor 18 and a secondary air compressor 19 ; the turbogenerator set includes a primary turbo expander 21 and a secondary turbo expander 22 .

[0046] The high-temperature cooler includes a first-level high-temperature cooler 23 and a second-level h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com