Harvester fuel tank assembly low in fuel consumption

A harvester and fuel tank technology, applied in the field of harvester fuel tank components, can solve problems such as difficult installation and maintenance, condensation of water in the fuel tank, and increased fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

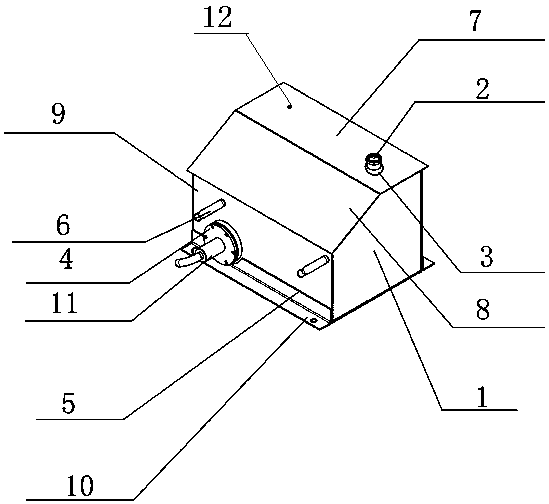

[0011] Such as figure 1 As shown, a fuel tank assembly for a harvester with low fuel consumption is characterized in that it includes a fuel tank body 1; the fuel tank body 1 is provided with a support panel 9, and the support panel 9 is provided with a rotary on-off valve 4, and on the rotary on-off valve 4 An oil injection pipe 11 is provided; a handle 6 is provided on the support panel 9, and reinforcing ribs 5 are provided under the handle 6; the support panel 9 is fixedly connected to the inclined panel 8, and the inclined panel 8 is fixedly connected to the upper panel 7; The upper panel 7 is provided with an air filter hole 3, the air filter hole 3 is provided with an air filter 2, and the upper panel 7 is provided with a bolt through hole 12; the support panel 9 is fixedly connected with the reinforced bottom plate 10; The angle between the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com