Quick spring collar dismantling device

A spring retaining ring, fast technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problem of small gaps, and achieve the effect of labor-saving disassembly and simple structure principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

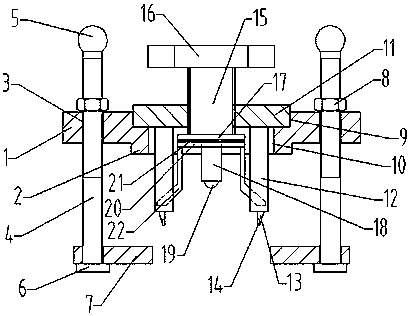

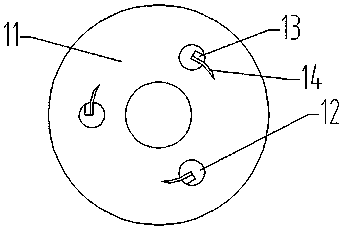

[0014] like Figure 1 to Figure 2 A spring retaining ring quick removal device shown in the figure includes a supporting circular plate 1, a load-bearing boss 2, a supporting threaded hole 3, a threaded rod 4, a knob ball 5, a limit baffle 6, a lower pressure plate 7, and a protective nut 8 , fitting circular groove 9, communicating hole 10, fitting circular plate 11, suspension rod 12, reinforcing rib block 13, square inserting plate 14, threaded column 15, rotating plate 16, connecting plate 17, pressing rod 18, positioning convex ball 19, Circular cover plate 20, copper gasket 21, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com