Vacuum adsorption terminal actuator for single-double box grasping

An end effector and vacuum adsorption technology, which is applied in the stacking of objects, destacking of objects, and manipulators, etc., can solve the problems of product, food contamination, limited clamping position, and easily damaged products, etc., to improve efficiency, The effect of reducing burden and ensuring diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings.

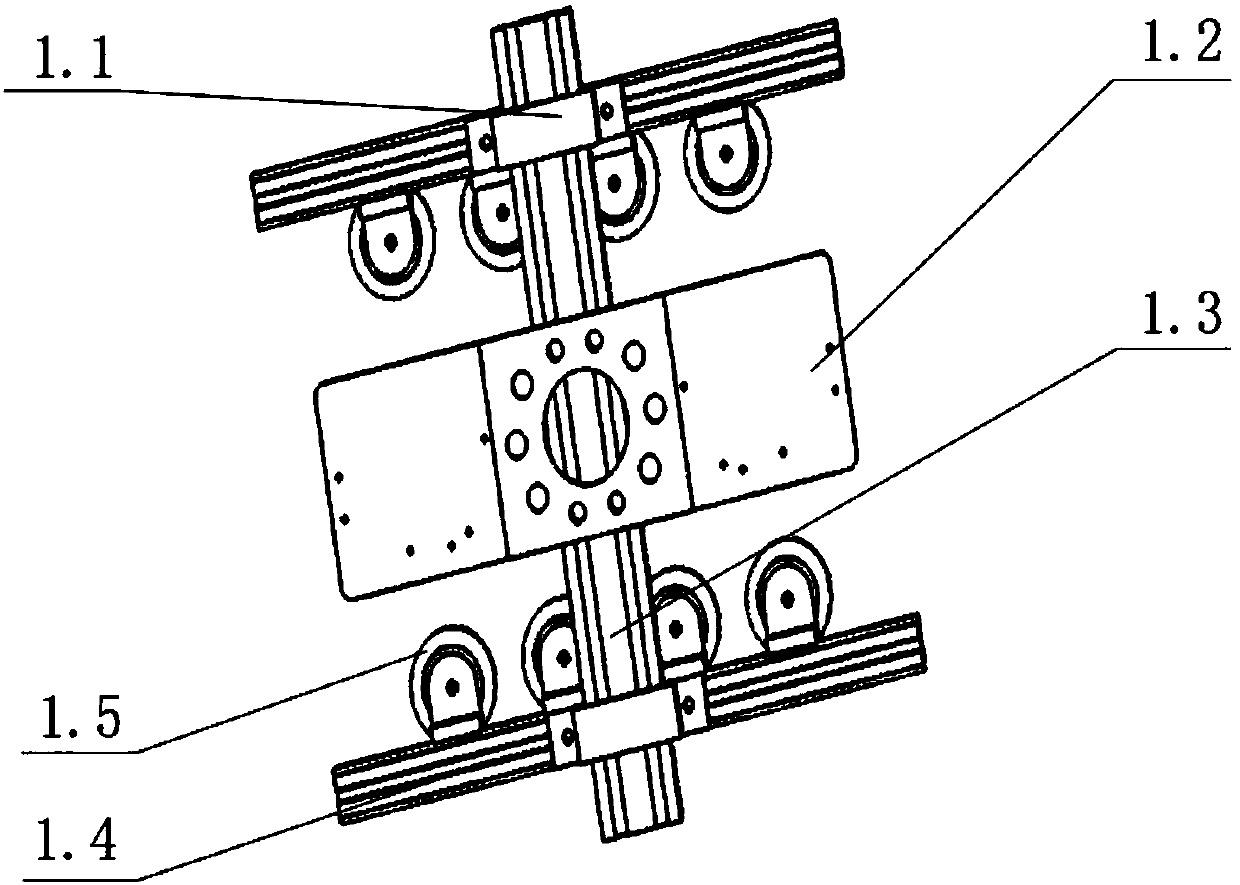

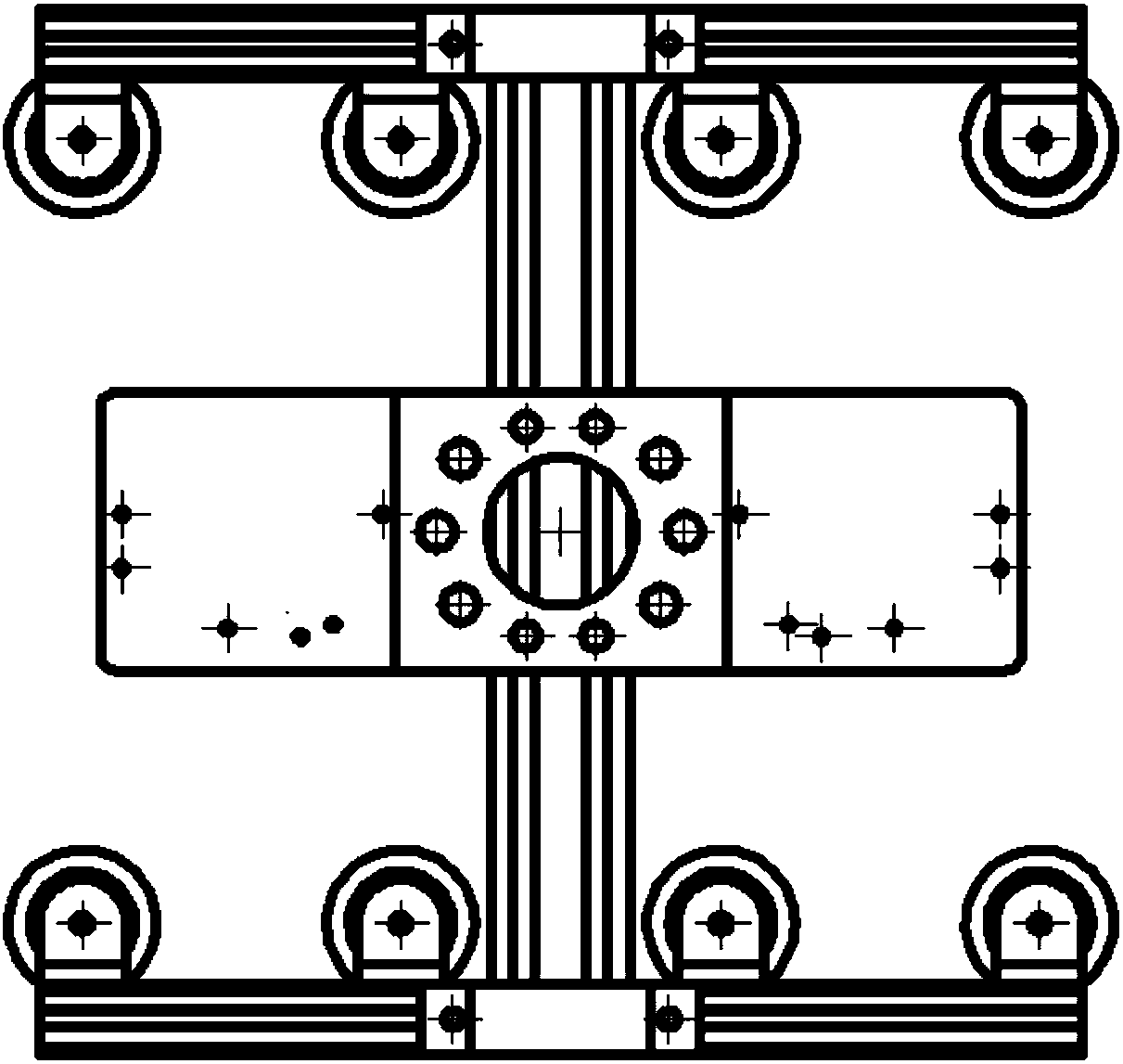

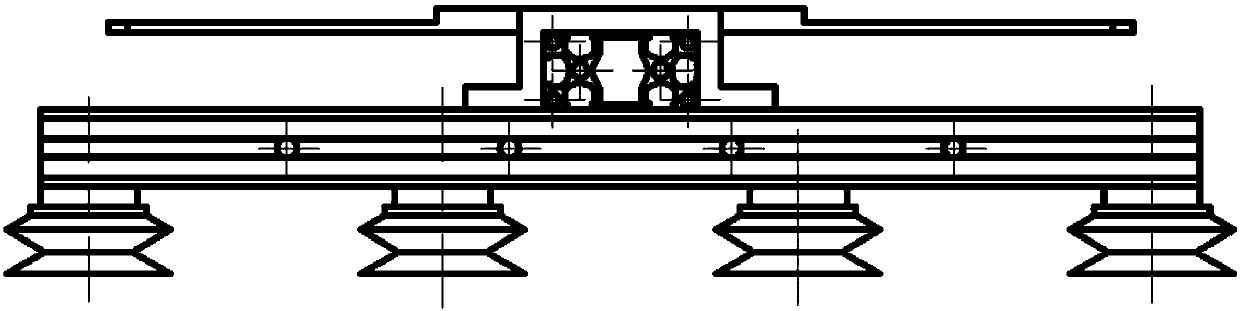

[0020] The vacuum adsorption type end effector used for grabbing single and double boxes in the present invention is as follows: Figure 1-3 As shown, it is composed of connecting block 1.1, connecting plate 1.2, longitudinal slide rail 1.3, transverse slide rail 1.4, vacuum adsorber 1.5, solenoid valve, etc.; connecting plate 1.2 is connected to the end of the mechanical arm through bolts, and connecting plate 1.2 is The rail 1.3 is connected with two identical connecting blocks 1.1, and the two identical connecting blocks 1.1 are respectively installed on two identical horizontal slide rails 1.4, and the vertical slide rail 1.3 is vertically arranged with the two horizontal slide rails 1.4, and the vertical slide rail 1.3 Connect the vacuum adsorber 1.5 via the connection block. The connection plate 1.2 is directly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com