Laser triggered multistage vacuum switch

A vacuum switch and laser technology, applied in electronic switches, spark gaps with auxiliary triggering devices, electrical components, etc., can solve problems such as limiting the application voltage level of laser-triggered vacuum switches, and avoid complex processes and high costs. The effect of large active area and improved conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

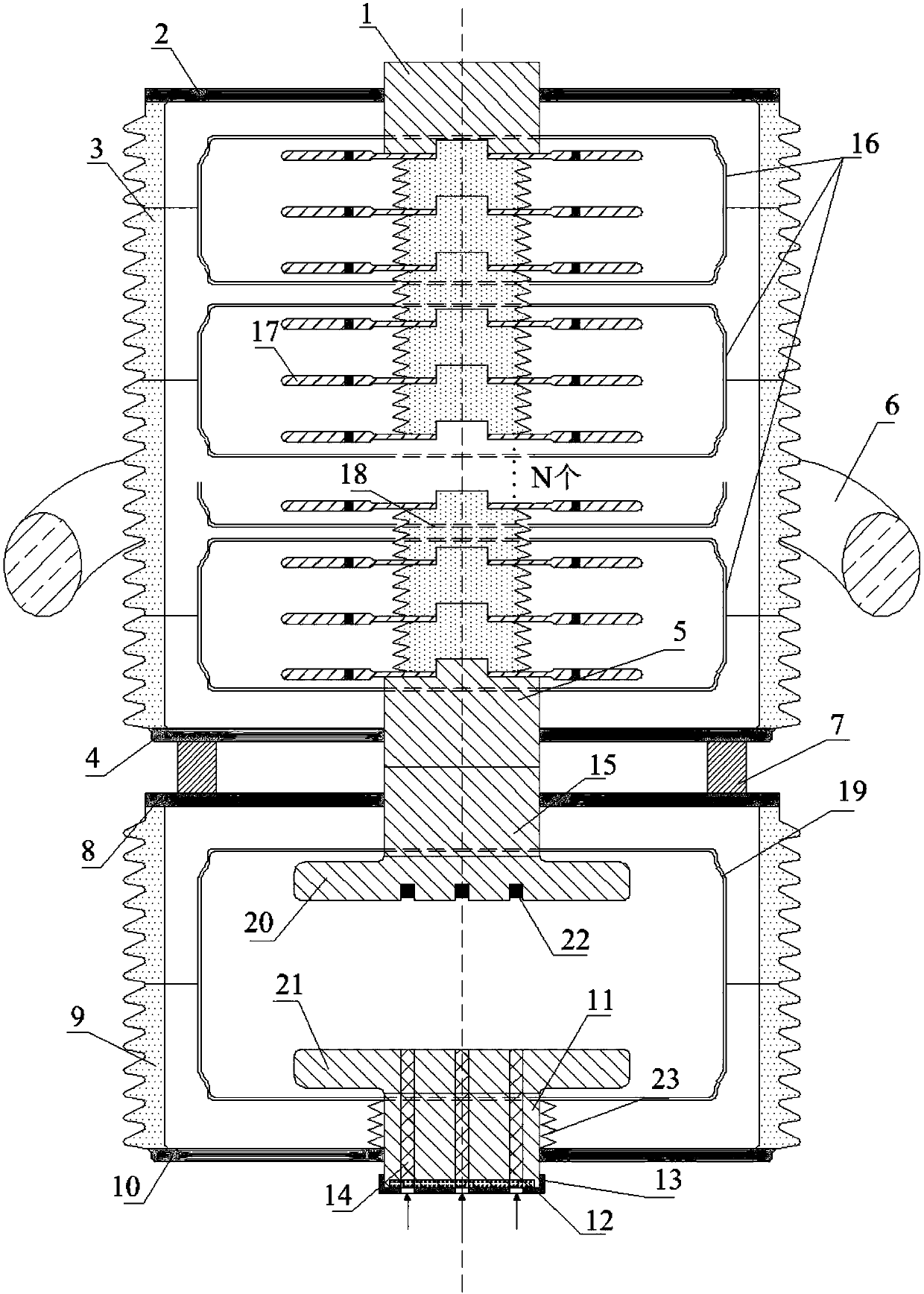

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

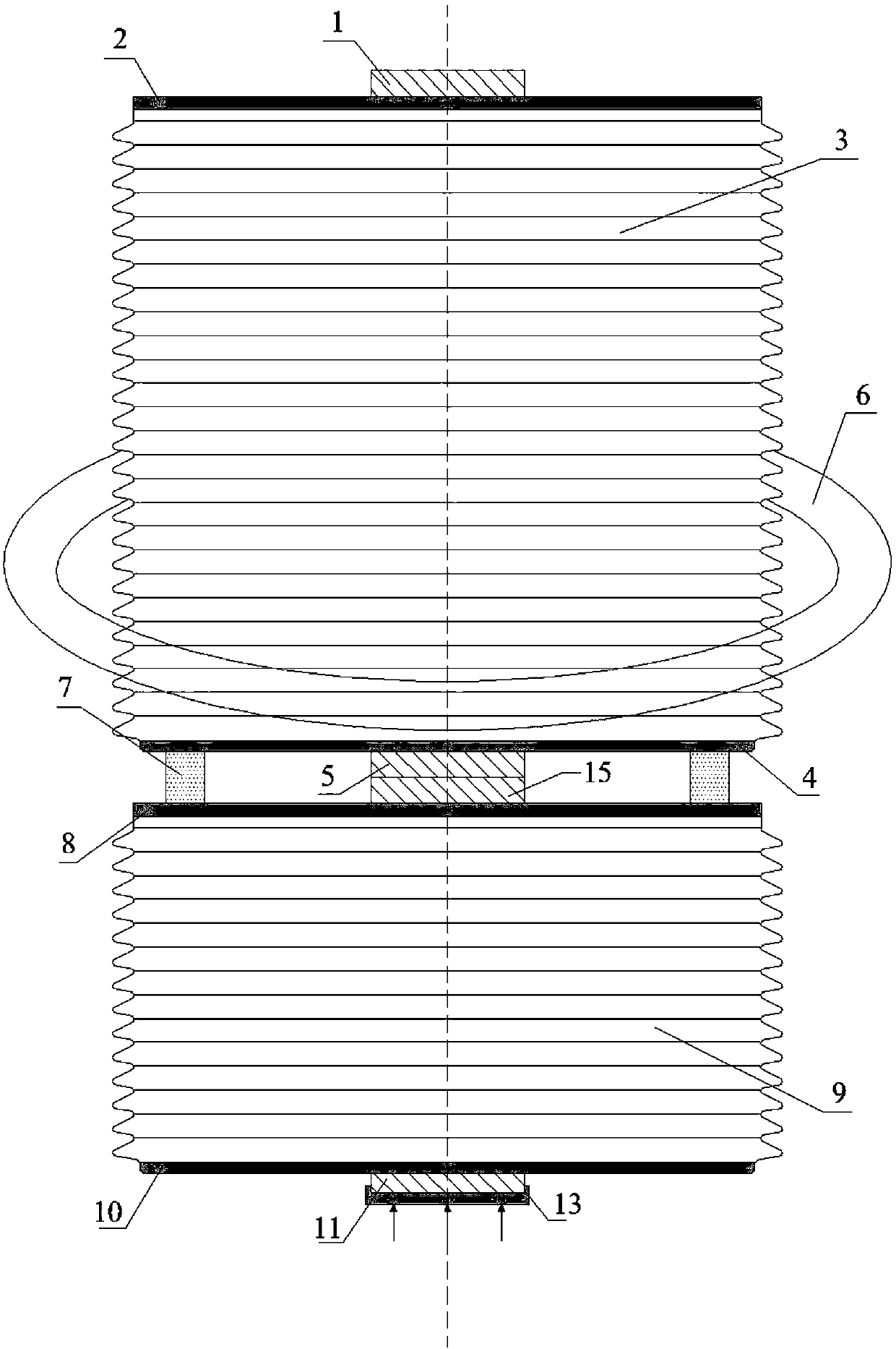

[0035] combine Figure 1 to Figure 6 , a laser-triggered multi-stage vacuum switch, comprising a laser-triggered vacuum gap, a multi-stage self-breakdown vacuum gap and a trigger system;

[0036] The multi-stage self-breakdown vacuum gap is fixed on the upper end of the laser-triggered vacuum gap through the fastening connector 7, and the pressure equalizing ring 6 is set outside the upper insulating shell 3;

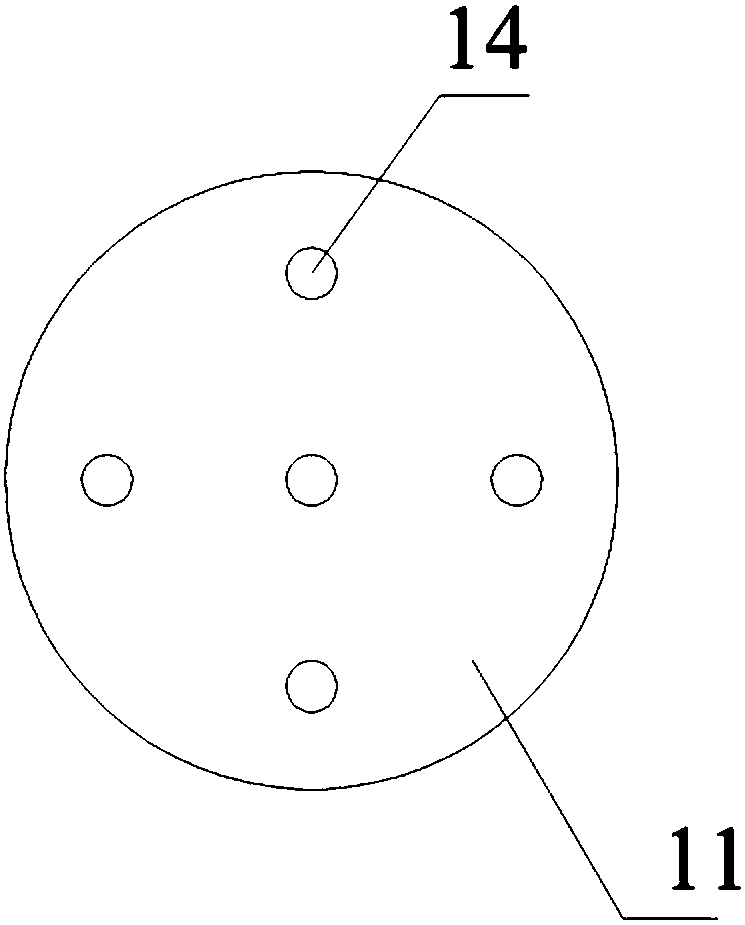

[0037] The laser trigger vacuum gap includes a lower insulating shell 9, a trigger upper end cover flange 8, a trigger gap shield 19, a trigger lower end cover flange 10, a cathode conductive rod 15, and a flat cathode contact 20 with multiple target electrodes. , Trigger target 22, flat anode contact 21 with multiple light holes, anode conductive rod 11 with multiple light holes, bellows 23, light lens 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com