A double-sided embossed different pattern multi-layer non-terry towel fabric and its weaving method

A terry-free, weave-free technology, applied in the direction of excavated fabrics, multi-strand fabrics, embossed fabrics, etc., can solve the problems of single color, insignificant difference, and monotonous pattern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

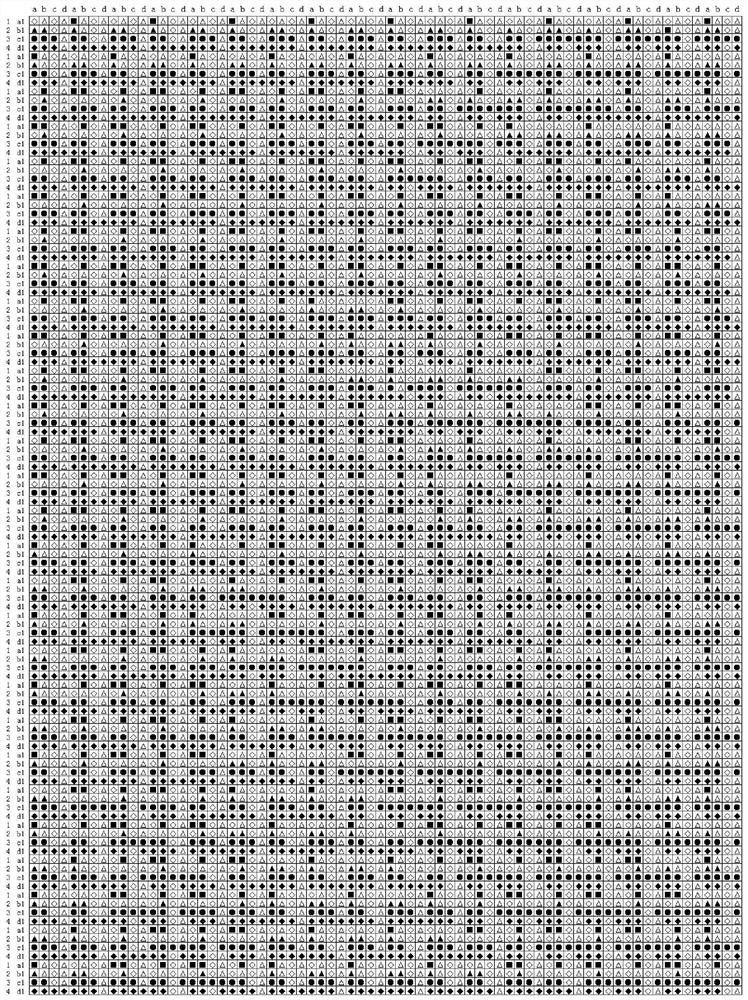

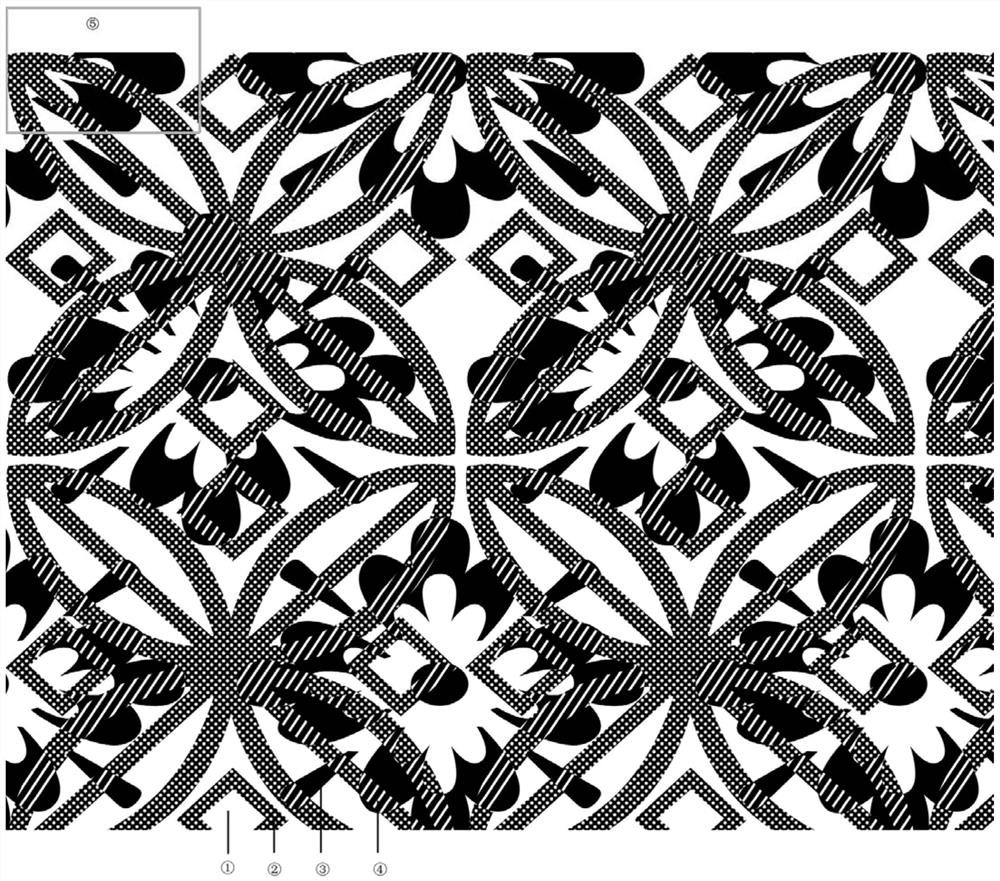

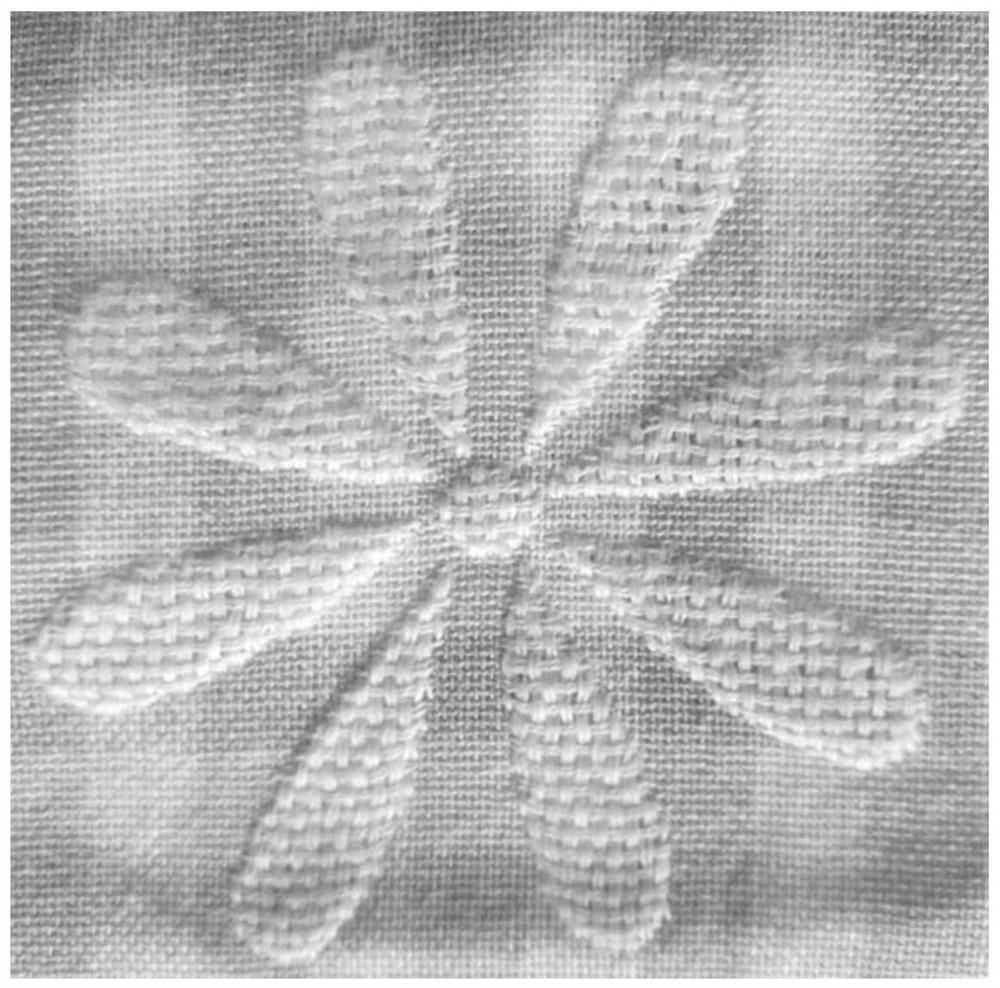

[0057] Yarn selection: Yarn-dyed A side cotton + B side cotton four-layer towel quilt, the ground warp is 32 S / 2 Cotton with 16 wool S Cotton (weak twist), weft is 32 S / 2 Cotton +16 S Cotton (weak twist). Reed number 64#, weft density 130 picks / 2.54cm.

[0058] The loom is Sulzer G6200 satin towel rapier loom from Switzerland, (the wool warp is 2 sheds, the ground warp is 1 heddle) / threaded into 1 reed, that is, 2 wool warps and 1 ground warp are threaded into the same reed tooth. The torsion value of the hair warp tension torsion bar is 68 degrees; the torsion value of the ground warp tension torsion bar is 30 degrees; the vehicle speed is 360 rpm.

[0059] According to different colors, the ground warp is divided into a-color ground warp and c-color ground warp; the wool warp is divided into b-color wool warp and d-color wool warp; The a-color weft yarn and b-color weft yarn corresponding to the color wool warp, and the c-color weft yarn and d-color weft yarn corre...

Embodiment 2

[0063] Yarn selection: yarn-dyed bamboo cotton on side A + super-imitation cotton in the middle + weak twist cotton on side B six-layer towel quilt, the ground warp is 32 S / 2 Cotton +32 S / 2 super imitation cotton +32 S / 2 Bamboo cotton with wool warp of 20 S Cotton +20 S Super imitation cotton +20 S Bamboo cotton, 32 weft S / 2 Cotton +20 S Cotton +32 S / 2 super imitation cotton +20 S Super imitation cotton +32 S / 2 bamboo cotton +20 S Bamboo cotton; reed number 80#, weft density 150 weft / 2.54cm.

[0064] Bamboo cotton is a yarn blended with bamboo fiber and cotton; super imitation cotton is a yarn blended with Yilun fiber and cotton.

[0065] The loom is Sulzer G6200 satin towel rapier loom from Switzerland, (the wool warp is 2 sheds, the ground warp is 1 heddle) / threaded into 1 reed, that is, 2 wool warps and 1 ground warp are threaded into the same reed tooth. The torsion value of the hair warp tension torsion bar is 65 degrees; the torsion value of the groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com