Beef jerk automatic drying device

A drying device and beef jerky technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problem of beef jerky losing its special flavor, etc., and achieve the effects of improving the drying effect, receiving the wind evenly, and increasing the relative speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

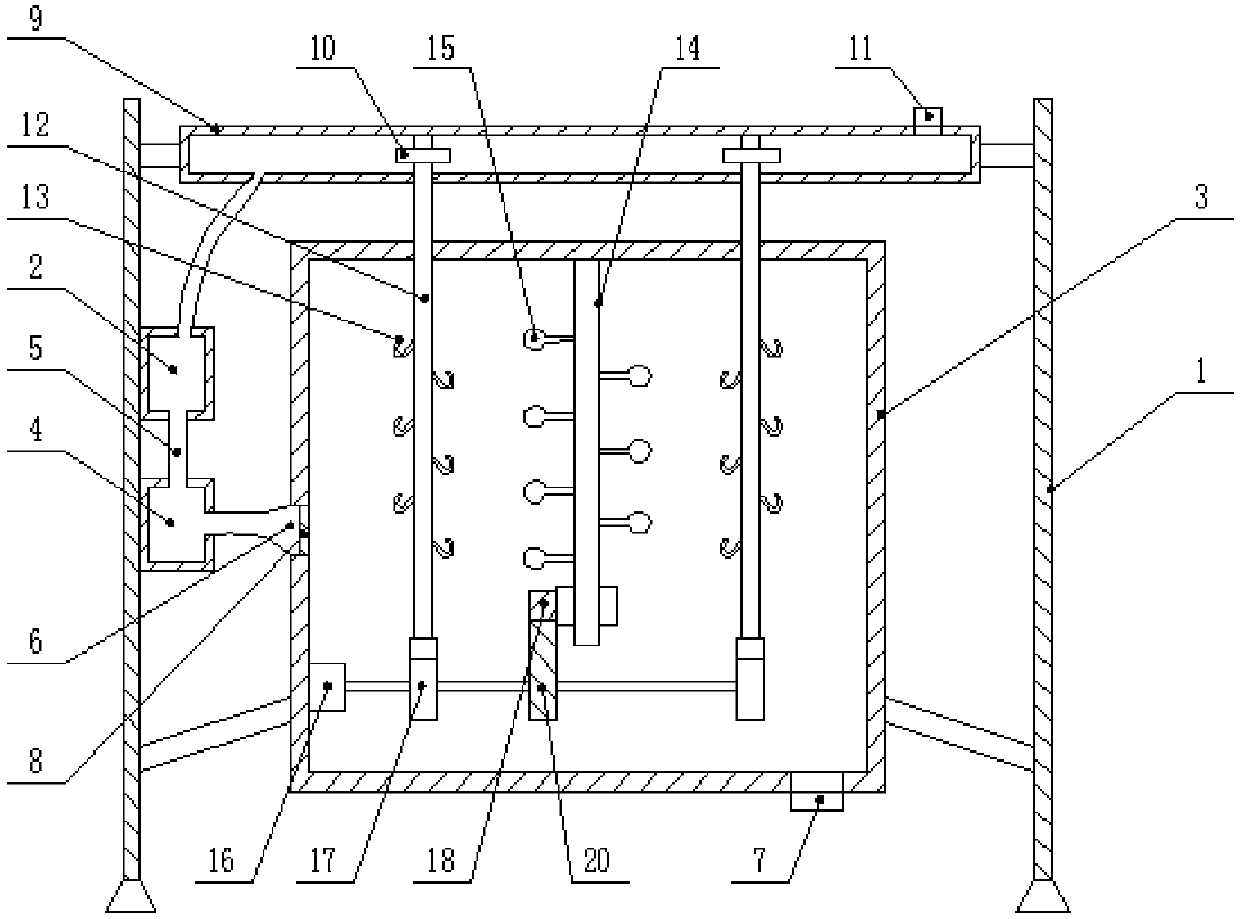

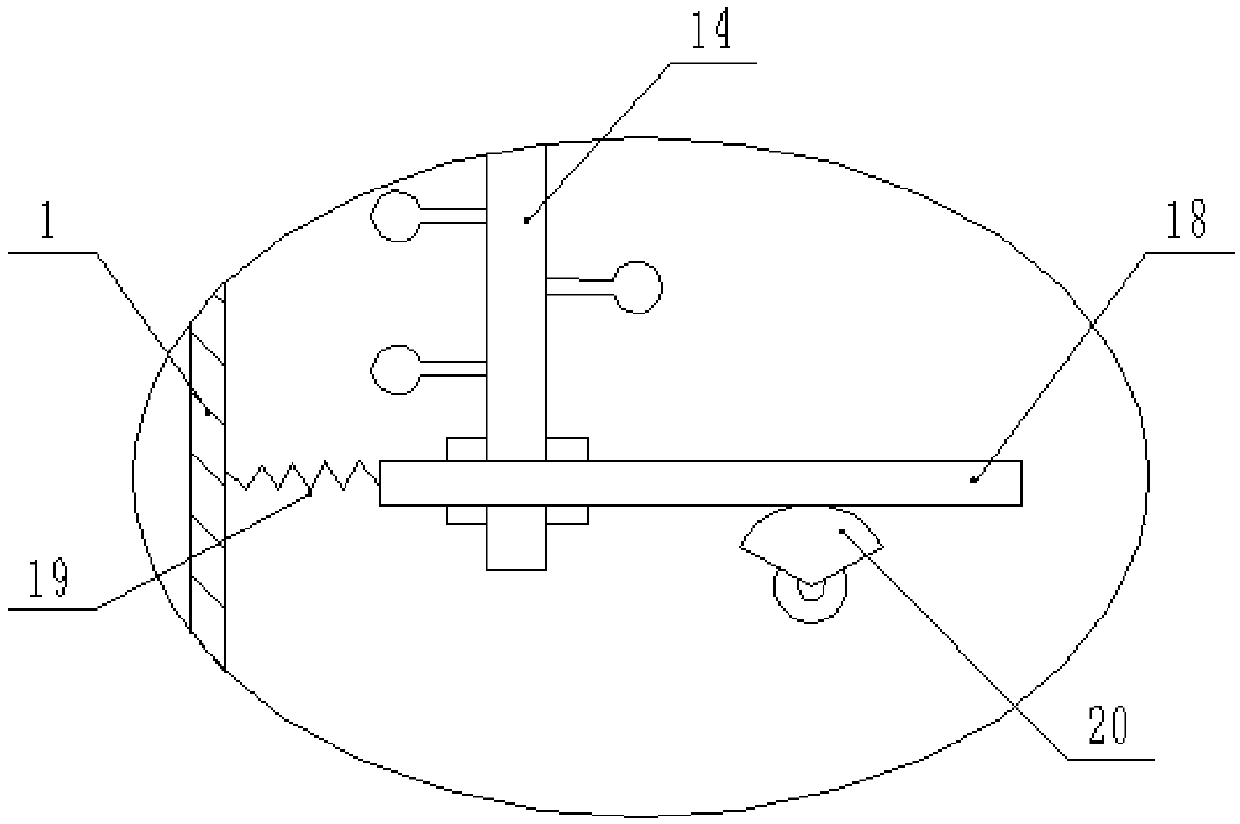

[0017] The reference signs in the drawings of the description include: frame 1, air supply box 2, drying box 3, drying box 4, duct 5, air inlet 6, air outlet 7, dustproof board 8, hollow board 9, turbine 10, Second air outlet 11, meat hanger bar 12, hook 13, shaft rod 14, meat hammer 15, motor 16, cam 17, slide bar 18, spring 19, fan gear 20.

[0018] The embodiment is basically as attached figure 1 , figure 2 Shown:

[0019] Beef jerky automatic drying device, including frame 1, air supply box 2 and drying box 3, both air supply box 2 and drying box 3 are installed on frame 1, and there is a drying box 4, between the air supply box 2 and the drying box 4, and between the drying box 4 and the drying box 3, there is a conduit 5, the drying box 4 is installed on the frame 1, and the drying box 3 is provided with an air inlet 6 and The air outlet 7, the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com