Cooling liquid filtering device for multifunctional turning lathe

A technology of filtering device and cooling liquid, applied in the field of lathes, can solve the problems of inconvenient cleaning, inconvenient cleaning operation, large volume of the collecting trough, etc., and achieve the effects of easy collection of chips and garbage, good lighting effect, and easy collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

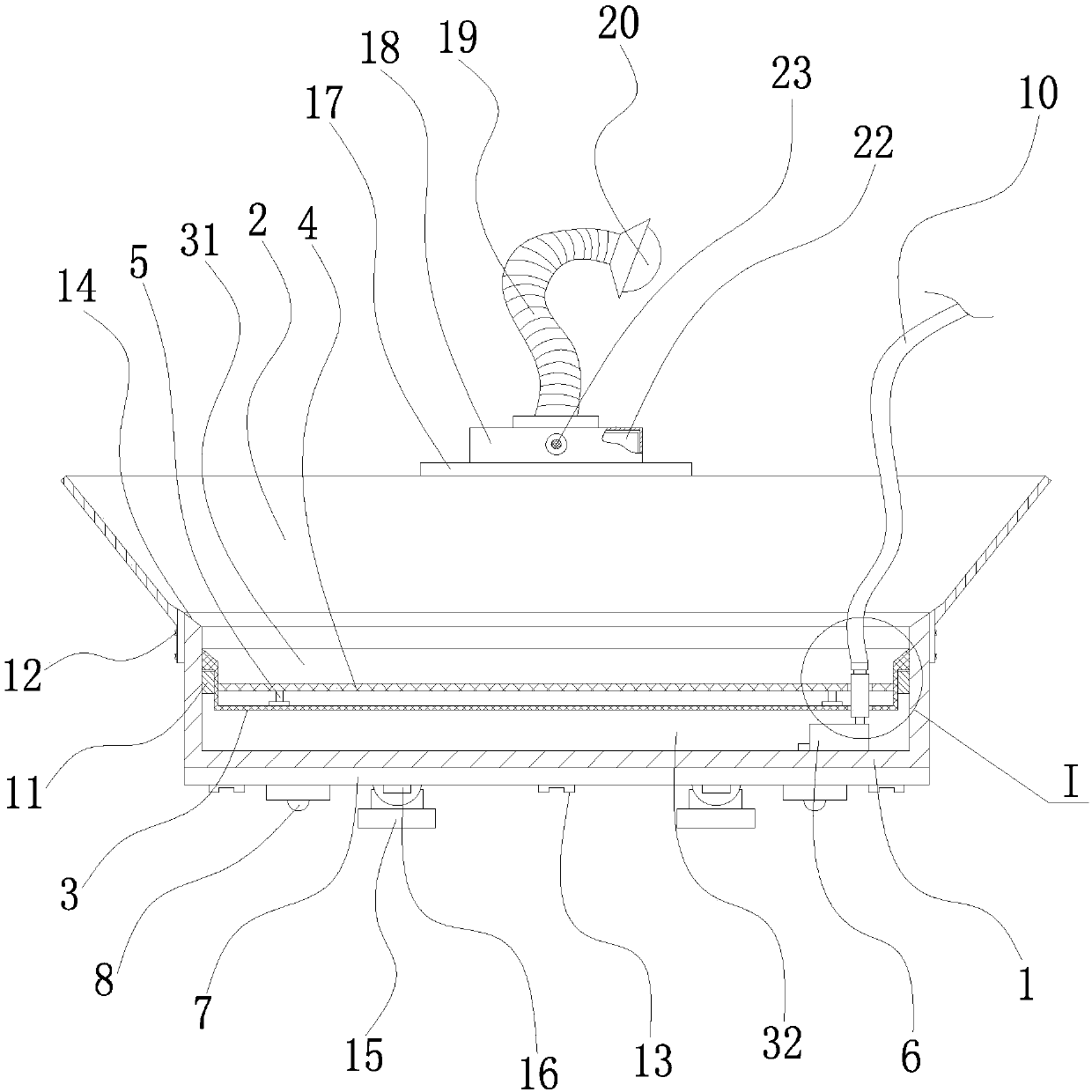

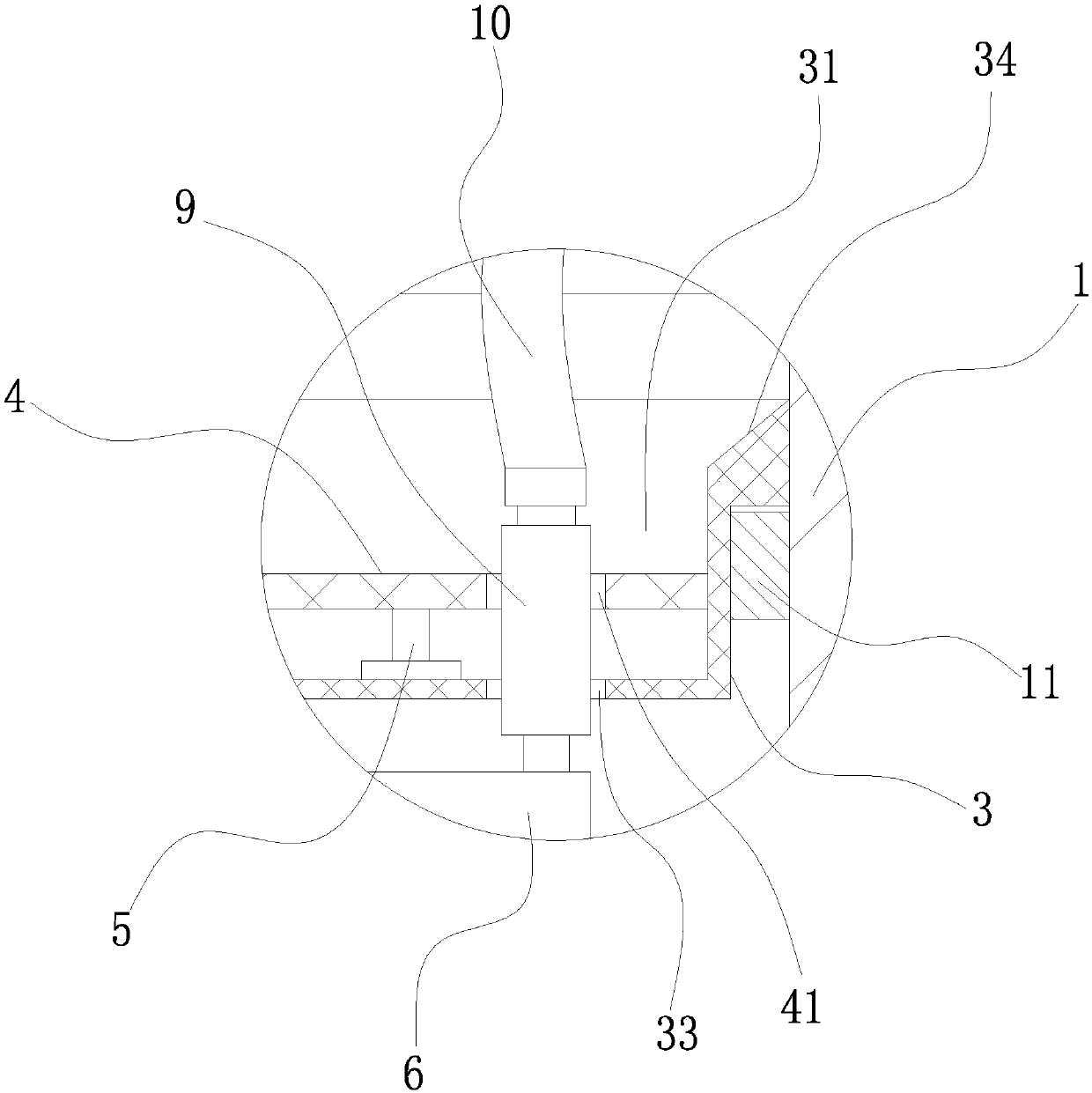

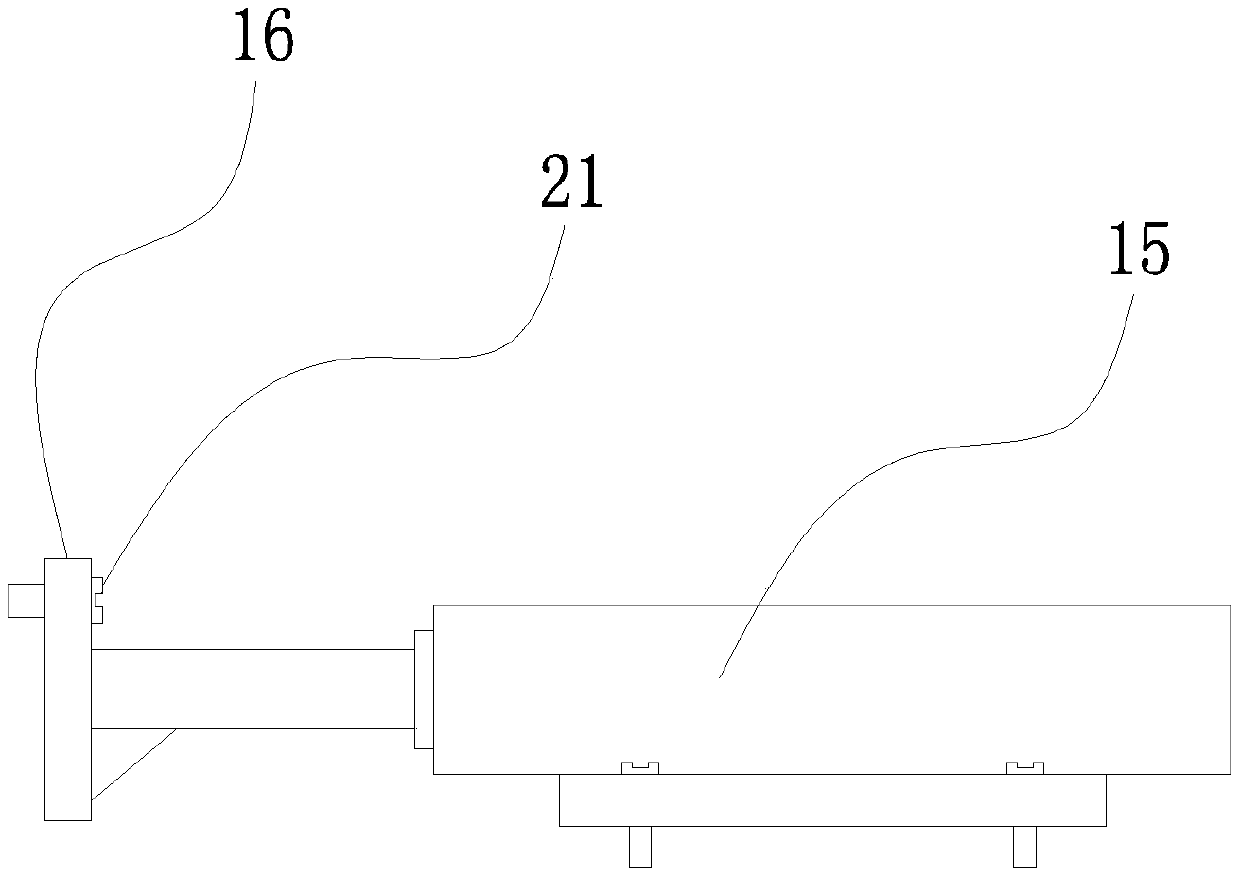

[0022] Example: such as figure 1 , figure 2 and image 3 As shown, a coolant filter device for a multifunctional lathe includes a collection tray 1, the upper end of the collection tray 1 is sleeved with a garbage guide cover 2, and the garbage guide cover 2 is detachably connected to the collection tray 1; The inner wall surface of the collection tray 1 is integrally provided with a positioning convex ring 11, a first filter net 3 is suspended on the positioning convex ring 11, and a filter net groove 31 is arranged in the middle of the first filter net 3 , there is a cooling liquid collecting cavity 32 between the lower end surface of the first filter screen 3 and the inner bottom surface of the collecting tray 1, and a second filter screen 4 is arranged in the filter screen groove 31, and the second filter screen A number of legs 5 are fixedly arranged on the lower end surface of 4; a water pump 6 is arranged in the cooling liquid collection cavity 32, and a cooling liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com