Automatic loading and unloading device for digital controlled lathe

A technology of automatic loading and unloading, CNC lathe, applied in metal processing and other directions, can solve the problems of low degree of automation, inability to realize bar material, large floor space, etc., to reduce labor intensity of workers, simple structure, small floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

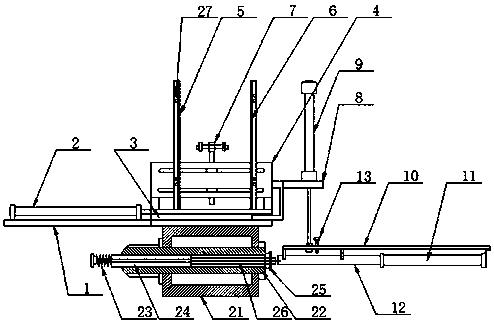

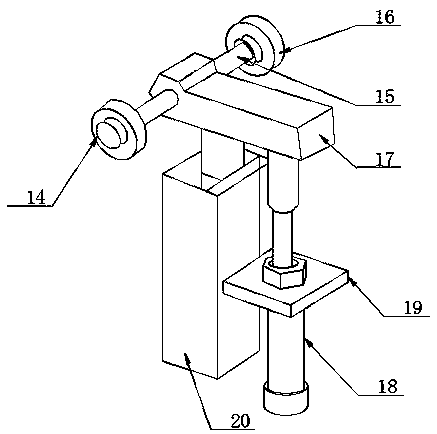

[0018] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

[0019] see as figure 1 —— figure 2 As shown, this specific embodiment adopts the following technical scheme: it includes a base 1, a material distribution cylinder 2, a material distribution tank 3, a hopper frame 4, a hopper 5, a material guide chute 6, an auxiliary blanking device 7, a feed cylinder support 8, Feeding cylinder 9, feeding cylinder support 10, feeding cylinder 11, barrel 12, positioning bolt 13; described base 1 is provided with distributing cylinder 2, distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com