Hot rolling line tooth coupling alignment tool and using method thereof

A technology of tools and wire teeth, which is applied in the field of aligning tools for hot-rolled wire teeth, can solve the problems of many quality problems of roller table teeth, short distance from the end face, and unsatisfactory measurement, and achieve less wear and tear of the teeth and plate Improved surface quality and improved alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further illustrated below by specific examples.

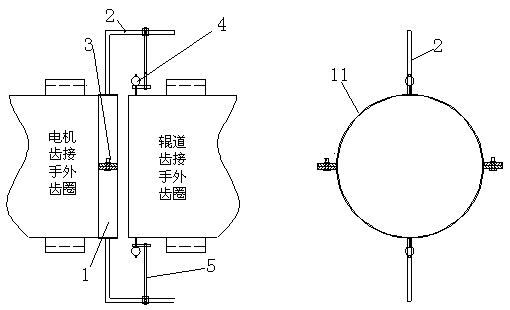

[0015] A hot-rolled wire gear alignment tool, including a ring 1 and a bracket 2, the ring includes two semicircular arms 11 and a hinge and a lock 3 connecting the two semicircular arms 1, The bracket 2 is arranged on the collar 1, and the bracket 2 is used to fix the dial gauge 4.

[0016] The hot-rolled wire teeth take over the alignment tool, and the bracket 2 is set at the 12 o'clock and 9 o'clock positions of the clasp 1 .

[0017] The method of using the hot-rolled line gear alignment tool includes

[0018] Step 1. Fix the two semicircular arms 11 with hinges and locks 3 on the motor side of the roller table to be measured and form a ring.

[0019] Step 2. Fix the bracket 2 at the 12 o'clock and 9 o'clock positions of the ring 1 respectively;

[0020] Step 3, install the dial indicator 4 on the bracket,

[0021] Step 4. Adjust dial indicator 4 to the measurement position, lock dial ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com