Negative-pressure transportation waste glass cleaning device

A cleaning device and waste glass technology, which is applied in the direction of transportation and packaging, conveyor objects, cleaning flexible objects, etc., can solve the problems of unclean cleaning and easy movement of waste cullet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

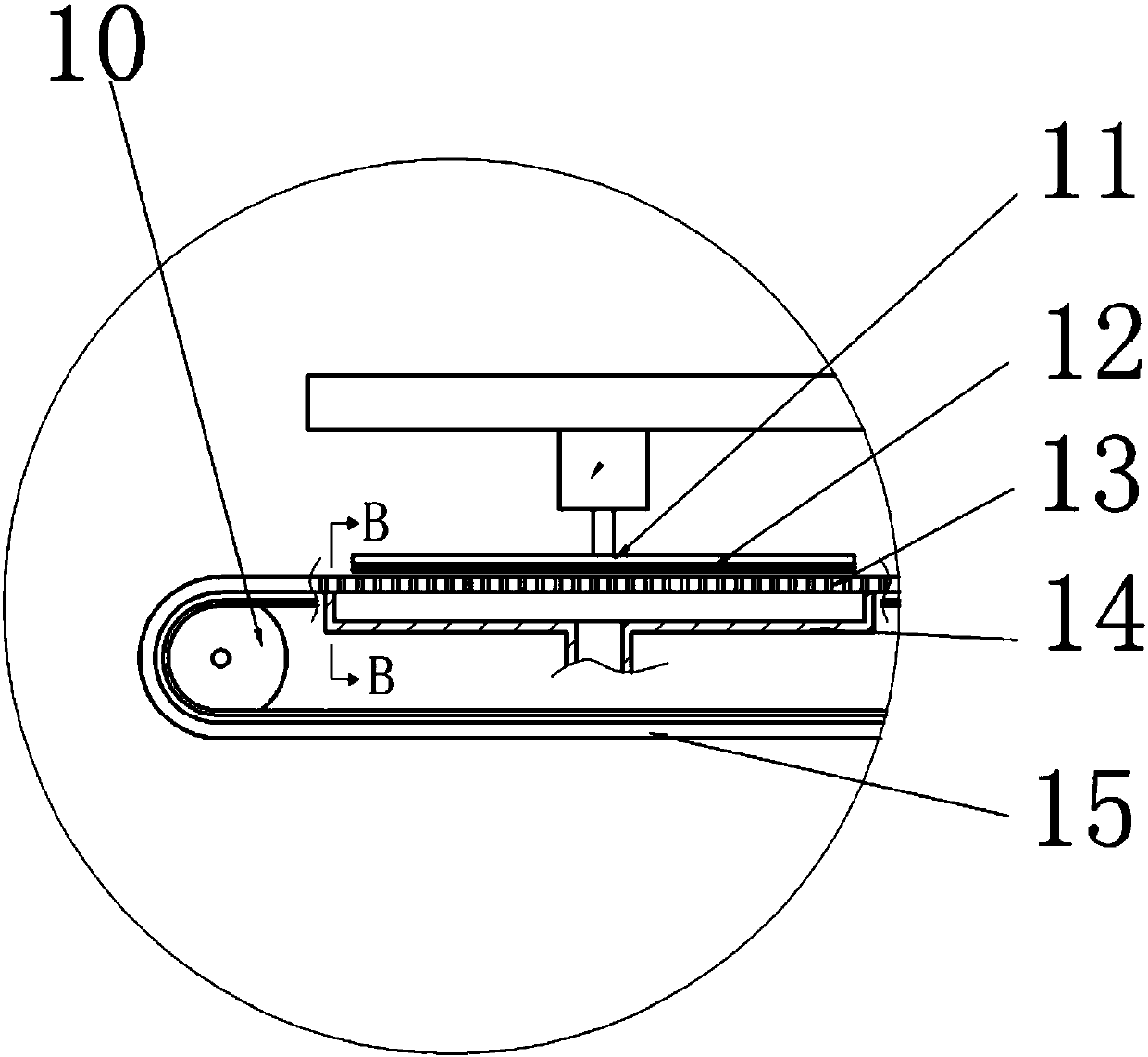

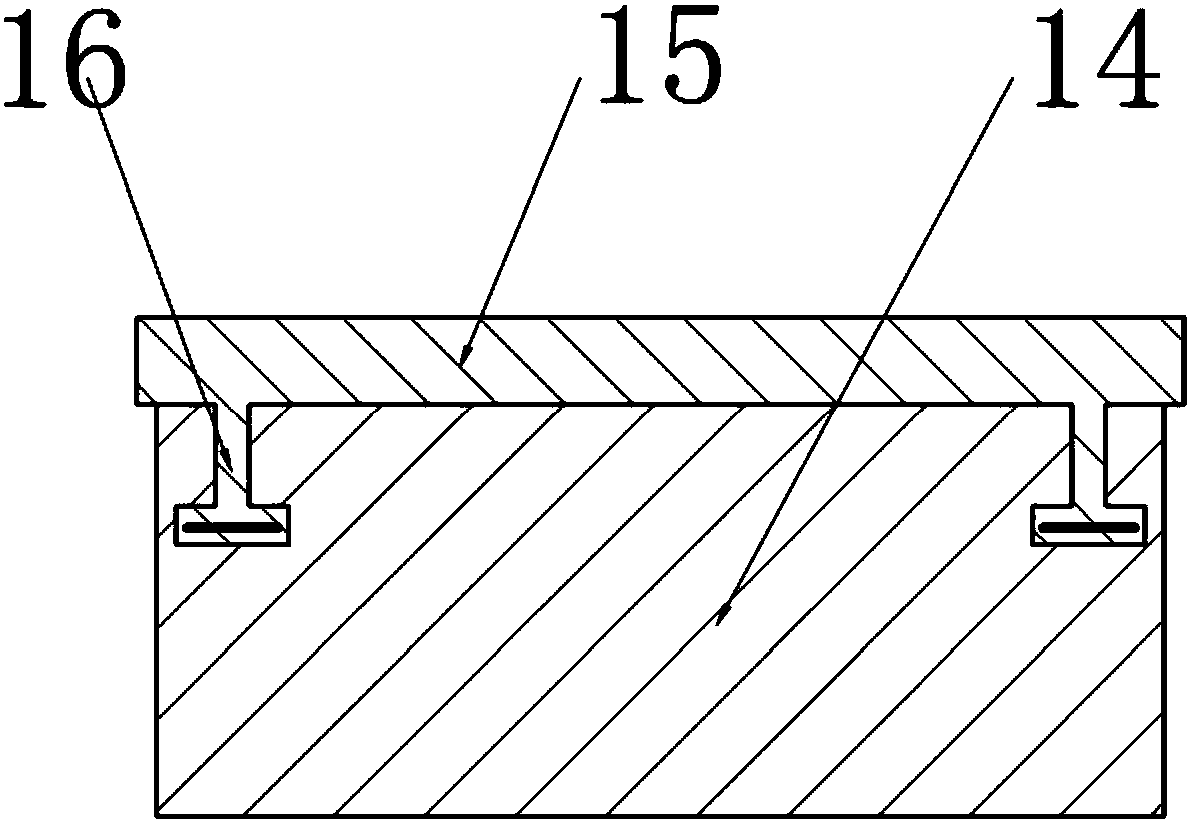

[0018] Embodiment: the negative pressure transportation waste glass cleaning device in this scheme, as figure 1 , figure 2 and image 3 As shown, it includes a frame, a horizontally arranged lower conveying cleaning device and an upper conveying cleaning device. The lower conveying cleaning device includes a first conveying motor, a first driving roller 5 and a first driven roller 10, and the first driving roller 5 and the second driving roller A driven roller 10 is rotatably connected to the frame, the first driving roller 5 and the first driven roller 10 are sleeved with a first conveyor belt 15, and a plurality of suction holes 13 are integrally formed on the first conveyor belt 15, and the first conveyor belt The motor is screwed to the frame. The output end of the first conveying motor is key-connected on the first drive roller 5 , and the top of the first conveying belt 15 is divided into a first adsorption cleaning zone and a first conveying zone along the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com