Dielectric voltage-withstand automatic test device for solar photovoltaic module

An automatic test device and a solar photovoltaic technology, applied in the field of solar photovoltaic, can solve problems such as positioning jig or positioning vehicle for positioning solar photovoltaic modules that are not shown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

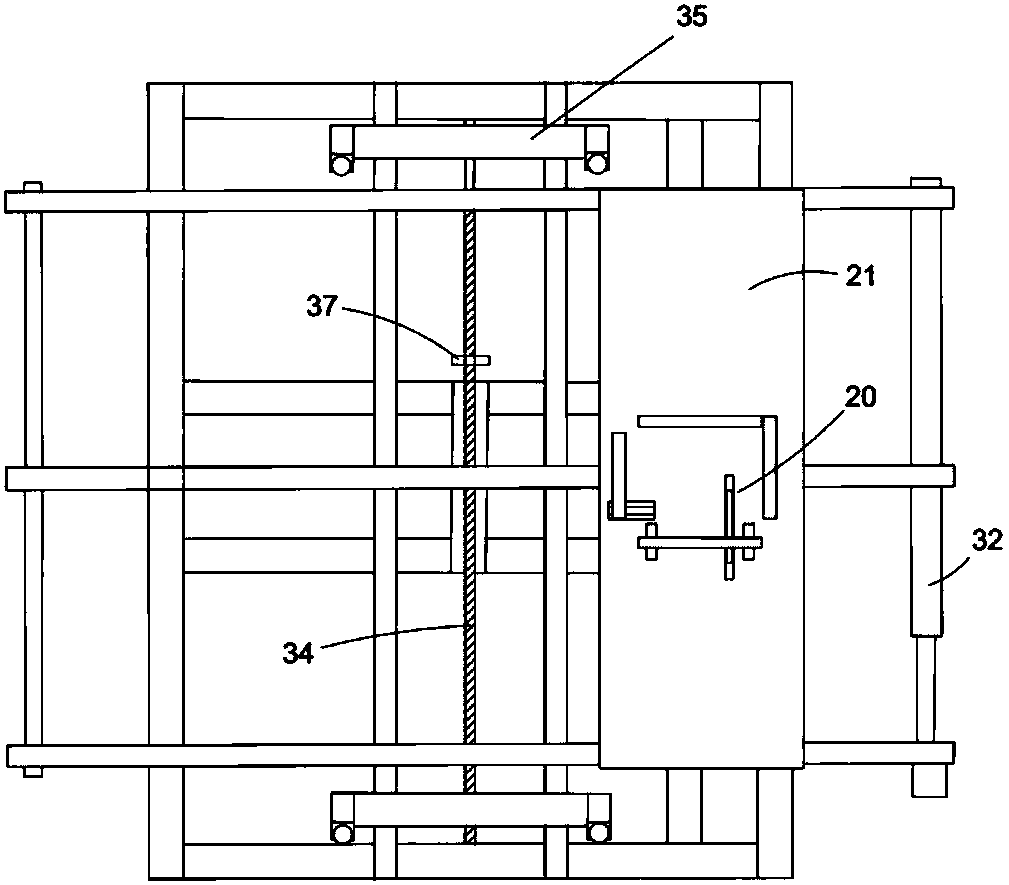

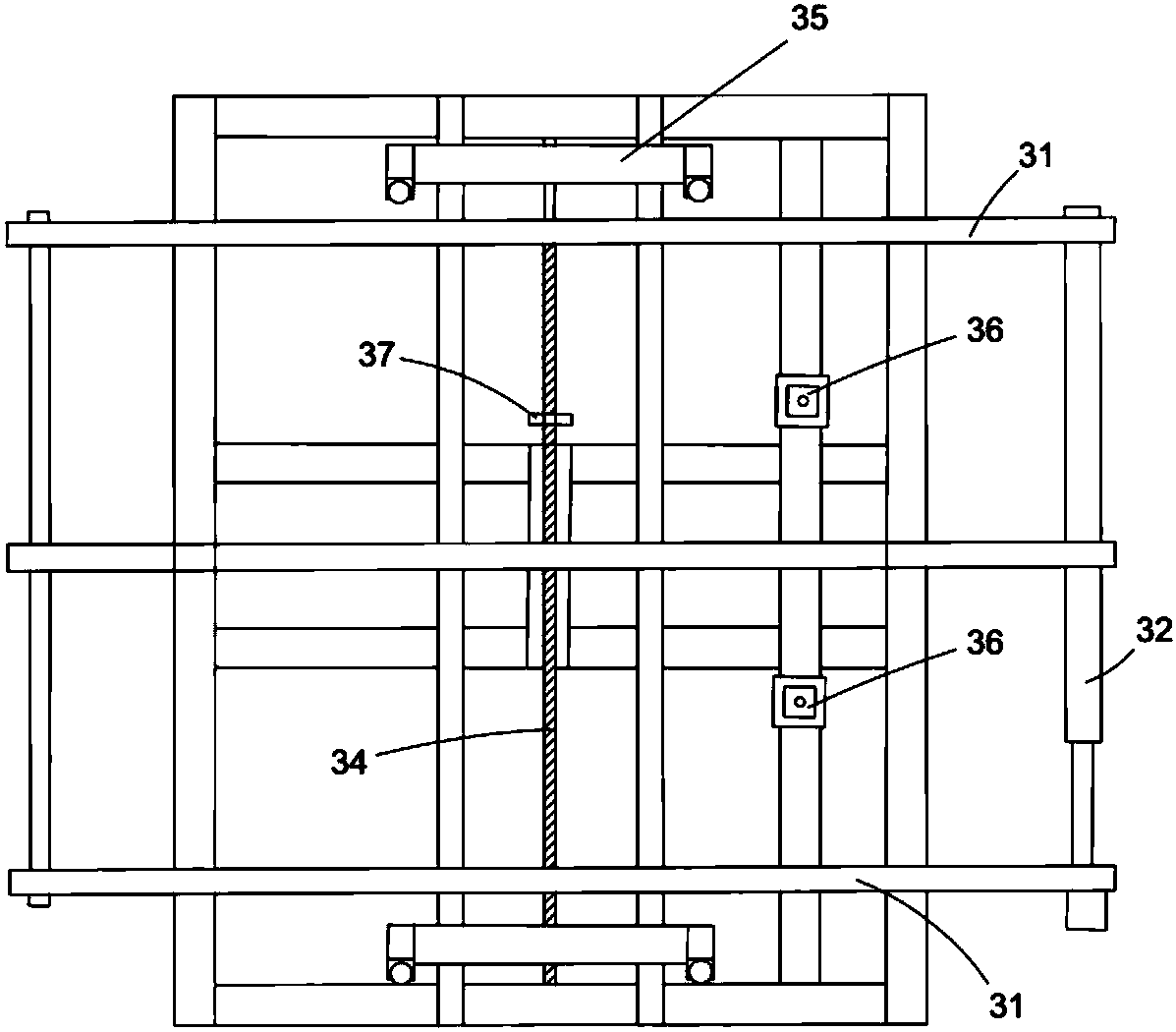

[0050] The following content reference Figure 1 to Figure 12 .

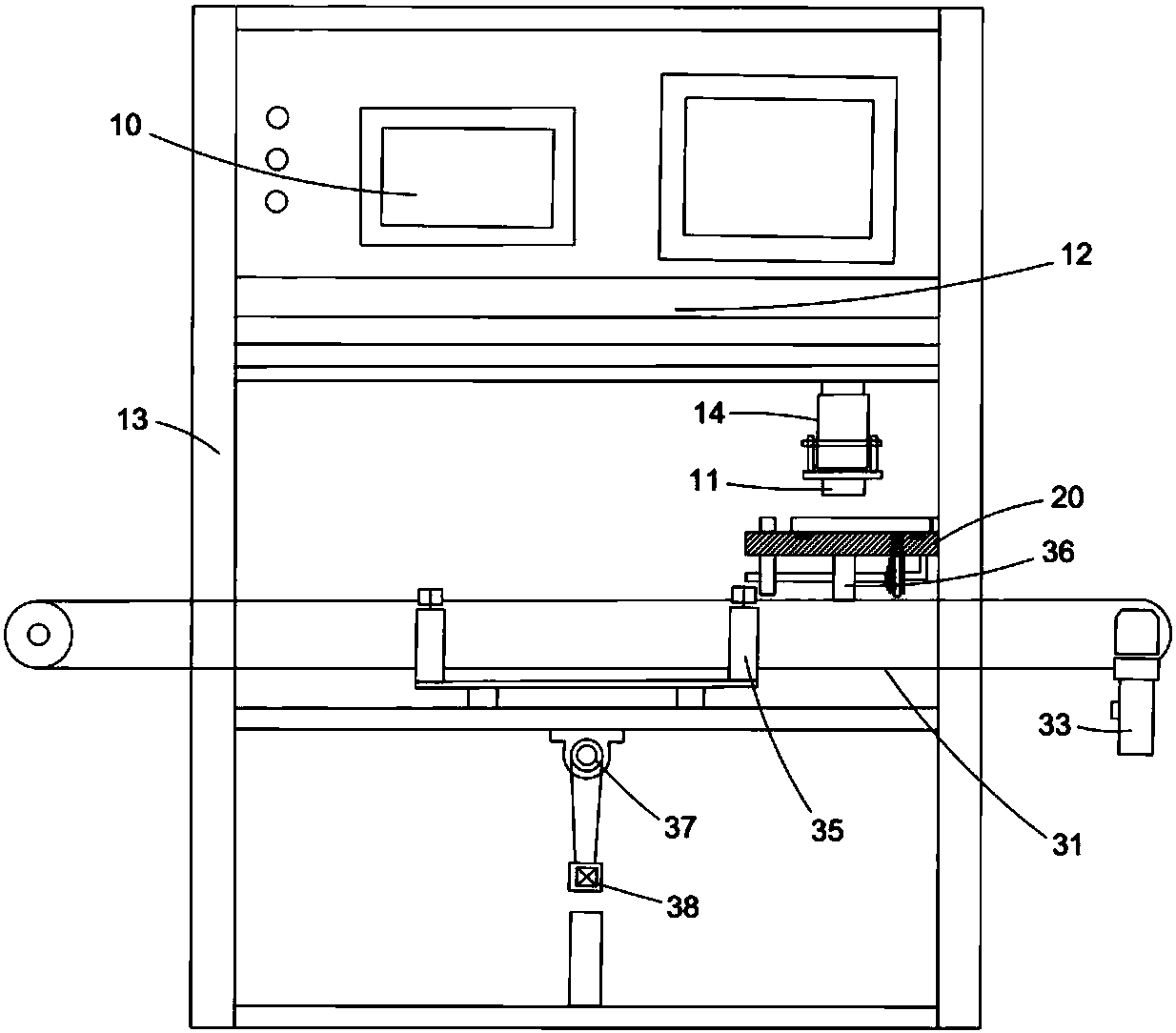

[0051] An automatic insulation and withstand voltage testing device for solar photovoltaic modules, including an insulation and withstand voltage tester 10 installed in a sealed isolation box, and a three-axis normalization mechanism for moving solar photovoltaic modules, the insulation and withstand voltage tester is set There is a contact probe 11, and a positioning carrier 20 is arranged on the three-axis normalization mechanism.

[0052] The insulation withstand voltage tester 10 is installed in a sealed isolation box 12, and the sealed isolation box is installed on the frame 13. One end of the probe cylinder 14 is fixed on the frame, and the other end of the probe cylinder is fixed with a contact probe 11. The probes are located outside the sealed isolation box and connected to the positive and negative terminals of the insulation withstand voltage tester.

[0053] The three-axis correction mechanism incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com