Waterproof A type USB connector female seat and manufacturing method thereof

A manufacturing method and connector technology, which is applied in the direction of connection, parts of the connection device, base/housing, etc., can solve problems such as the mother seat cannot be waterproof, burn out the circuit board, and endanger life safety, so as to meet the requirements of mechanical functions and electronics. Effect of performance parameter requirements on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

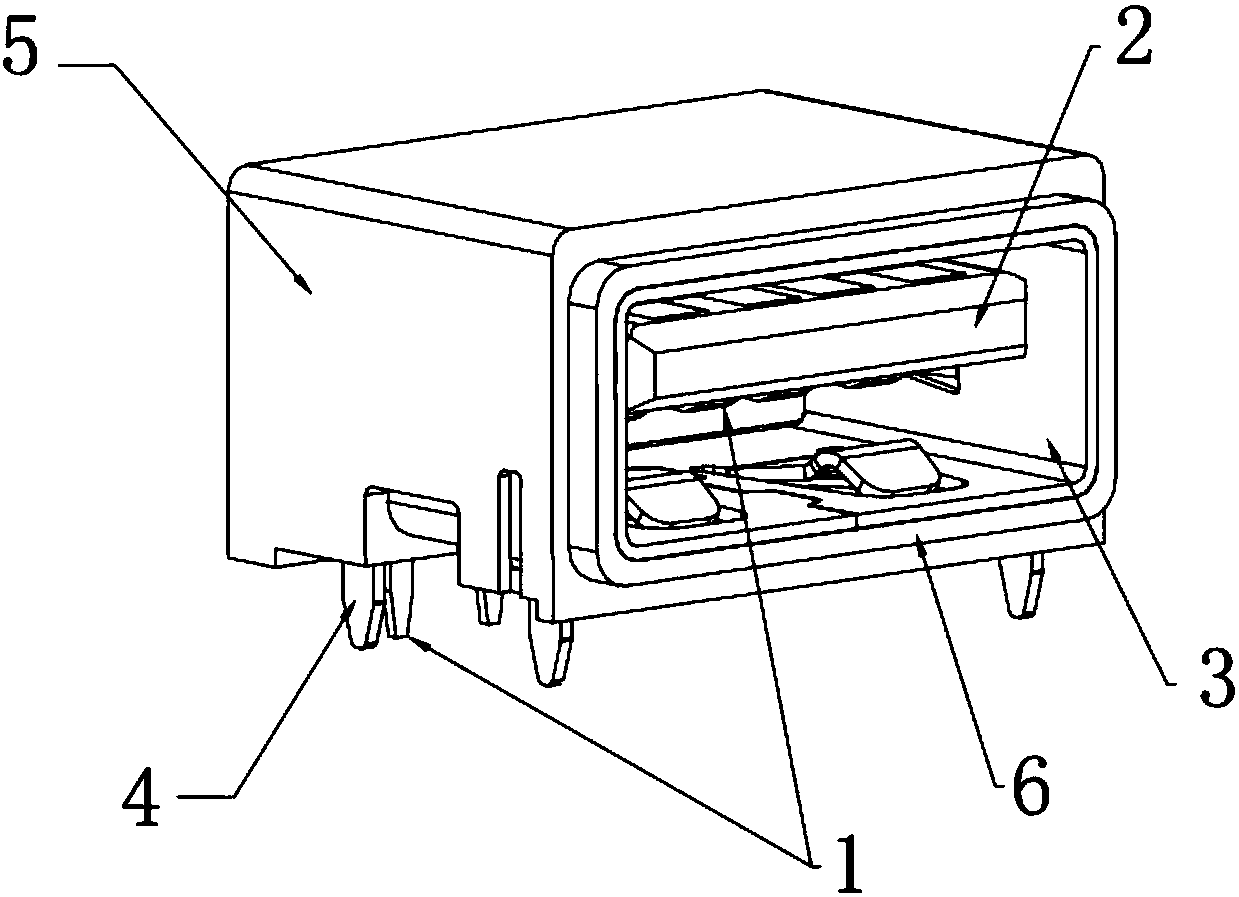

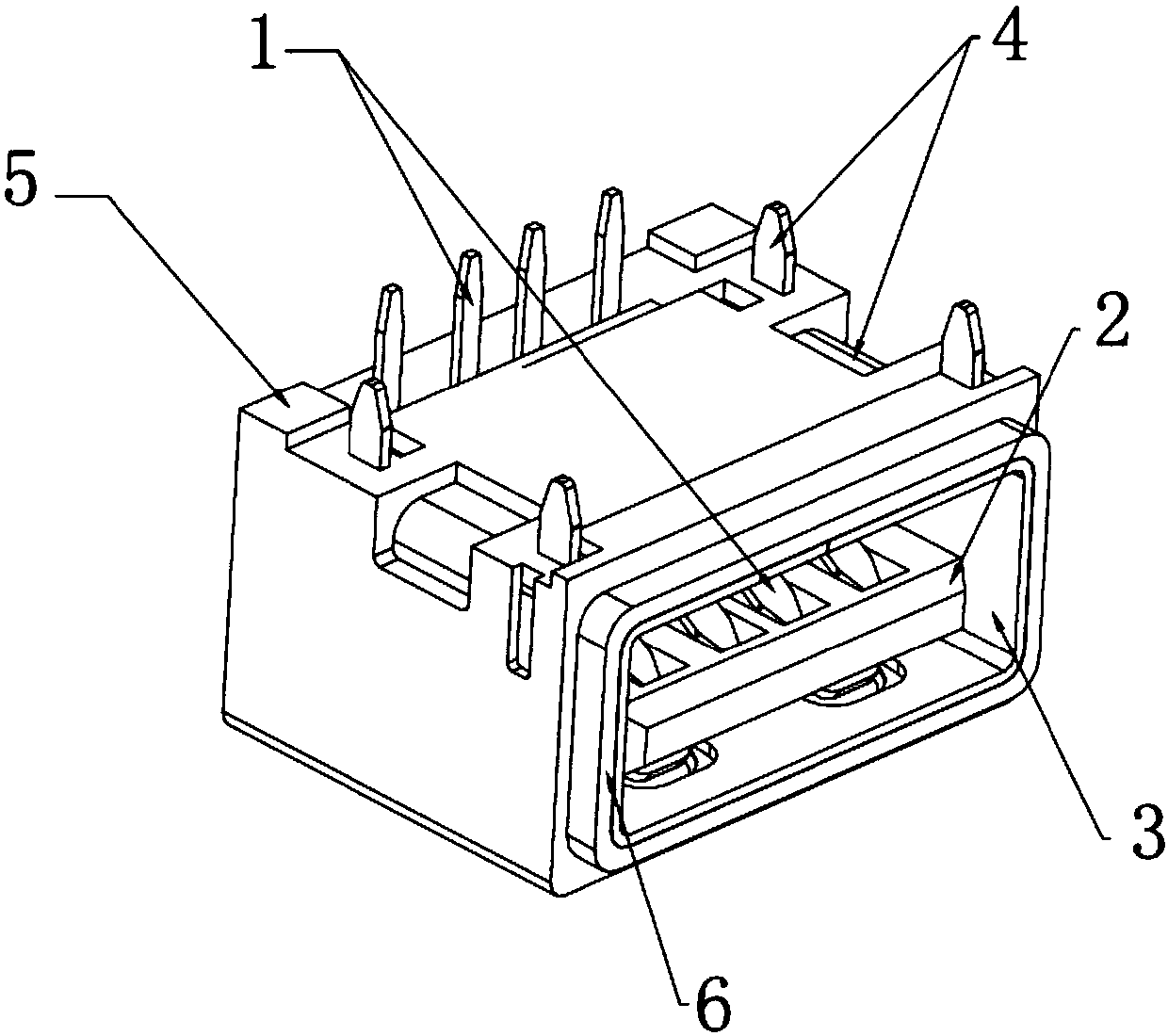

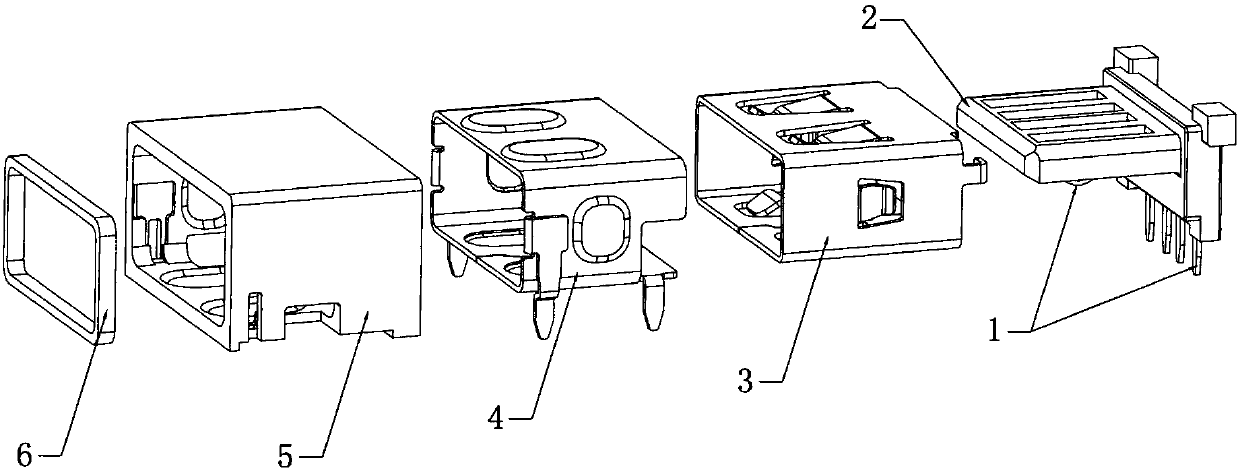

[0032] a kind of like figure 1 , 2 3. The waterproof A-type USB connector female seat shown in 3 includes four connecting pins 1, a rubber core 2, and an injection-molded polyamide shell 5. The connection pin definition and package size conform to the USB 2.0 protocol.

[0033] The rubber core 2 is a rubber core integrally injection-molded with the four connecting pins 1;

[0034] Inside the shell 5 are an inner shell 3 assembled with the rubber core 2 and a middle shell 4 attached outside the inner shell 3. The inner shell 3 is provided with four shrapnels on the top and bottom, and two on the left and right. Shrapnel, when the male head is inserted, it is subject to a certain elastic force to ensure that the male head is inserted up and down and left and right in the center. The middle shell 4 is a metal shell, which is used to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com