Fence construction method and fence module with self-test type spraying device for pipe

A construction method and sprinkler technology, applied in the direction of fences, cleaning methods, road cleaning, etc., can solve the problems of being easily crushed by vehicles or trampled by workers, blockage of spray pipes, heavy workload, etc., to achieve convenient assembly Fast, reduce workload and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

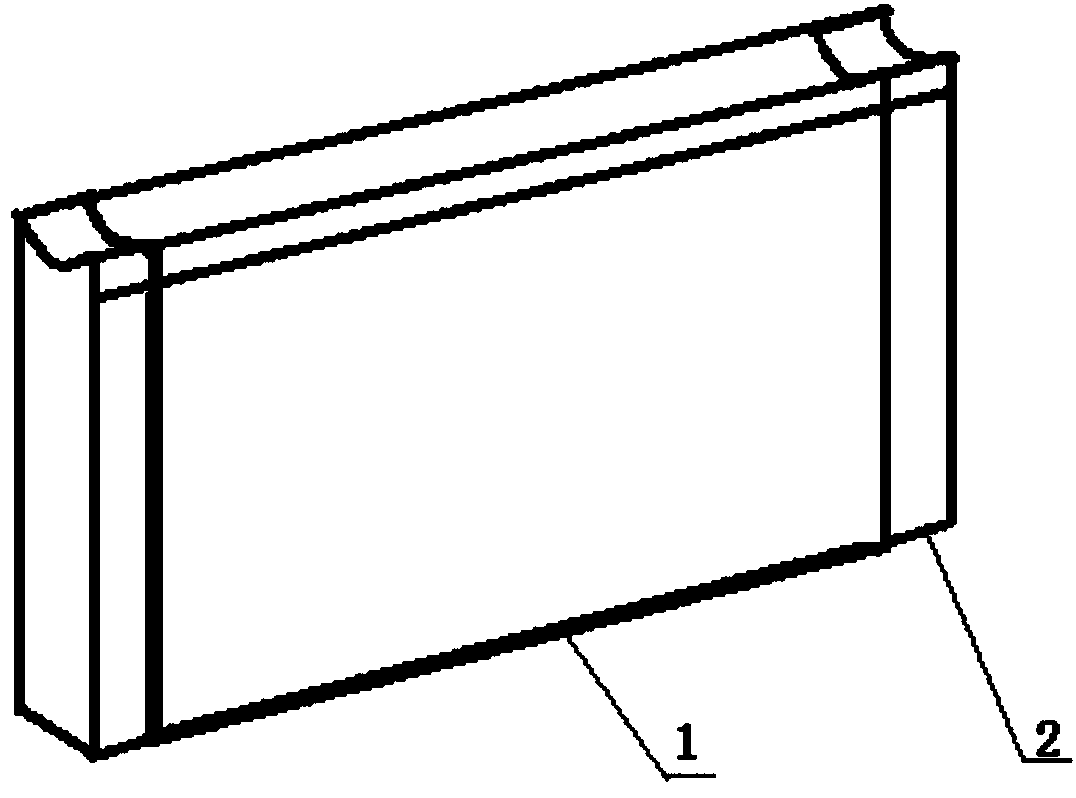

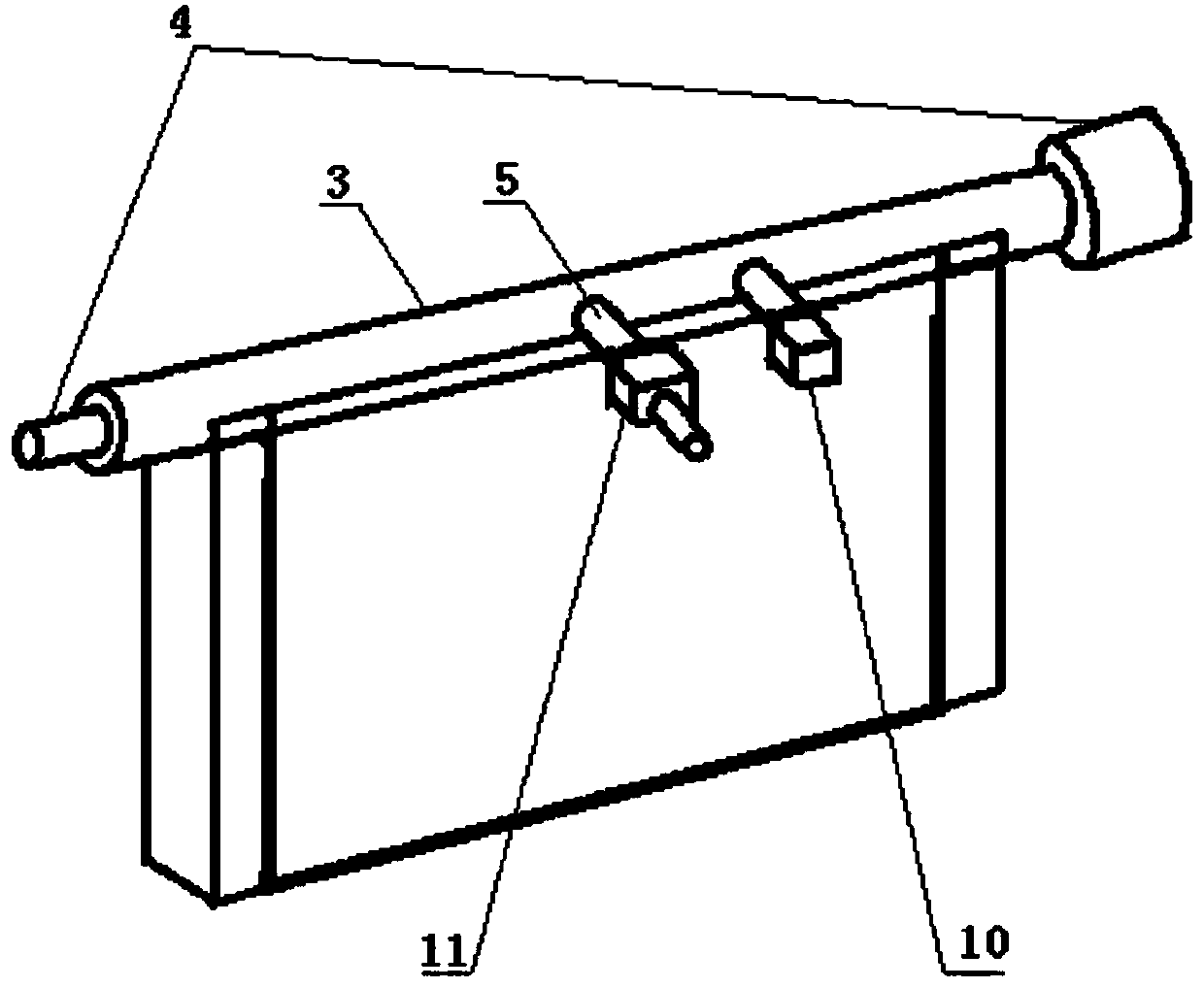

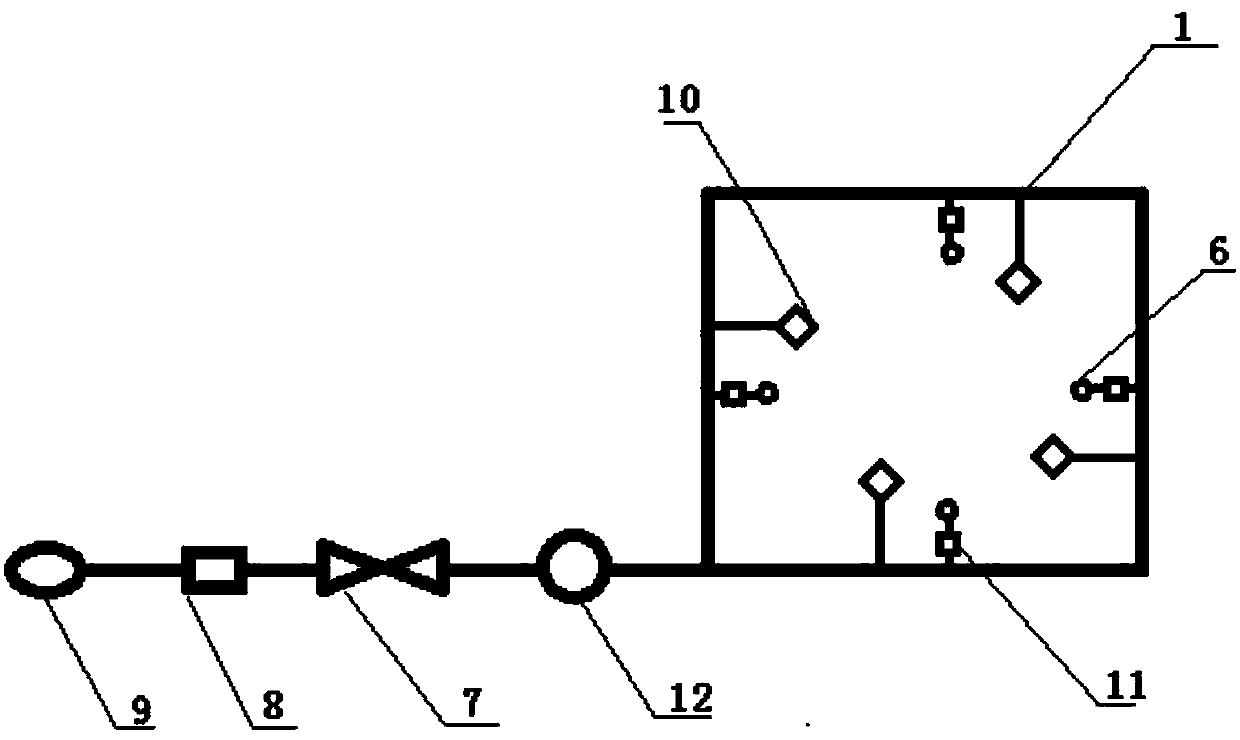

[0023] Below in conjunction with accompanying drawing and embodiment the present technical scheme is described, figure 1 It is a schematic diagram of the fence 1 and the fence column 2, figure 2 It is a schematic diagram of the enclosure module, including the enclosure baffle 1, the enclosure column 2 and the spray pipe 3, the middle part of the pipe wall of the spray pipe 3 is provided with a connecting pipe 5, the connecting pipe 5 is used to connect the nozzle 6, and the connecting pipe 5 An electromagnetic valve 11 is provided, and a male buckle and a female buckle of the AD-type quick connector 4 are respectively provided at both ends of the spray pipe 3, so that the spray pipes 3 can be quickly assembled and disassembled. The spray pipe 3 is placed above the baffle plate 1 and the baffle column 2, the two ends of the baffle plate 1 are connected with the baffle column 2, the upper ends of the baffle plate 1 and the baffle column 2 are provided with grooves, and the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com