Desilting operation ship

A technology for working boats and silt, applied in the direction of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve problems such as loss of water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

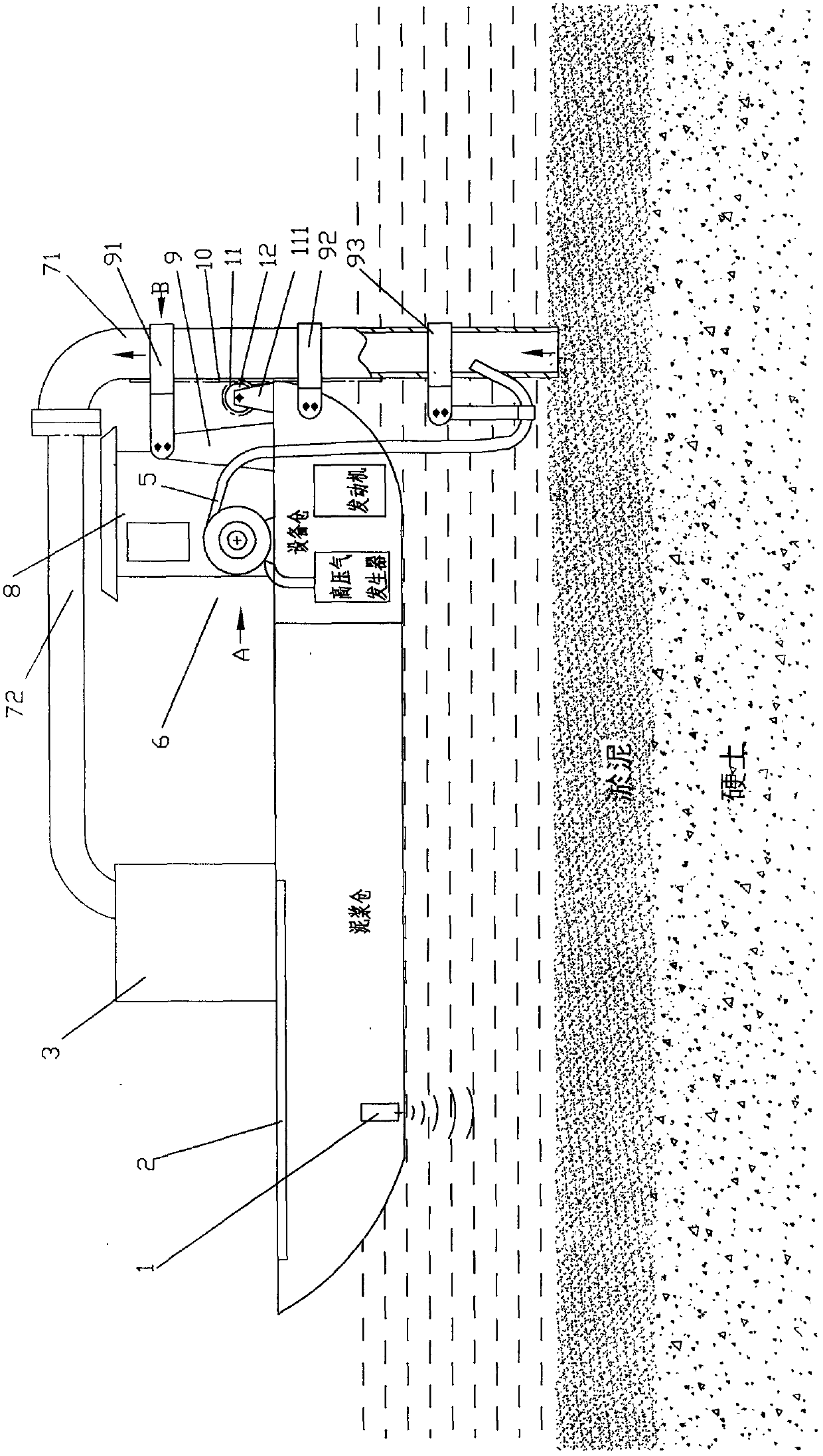

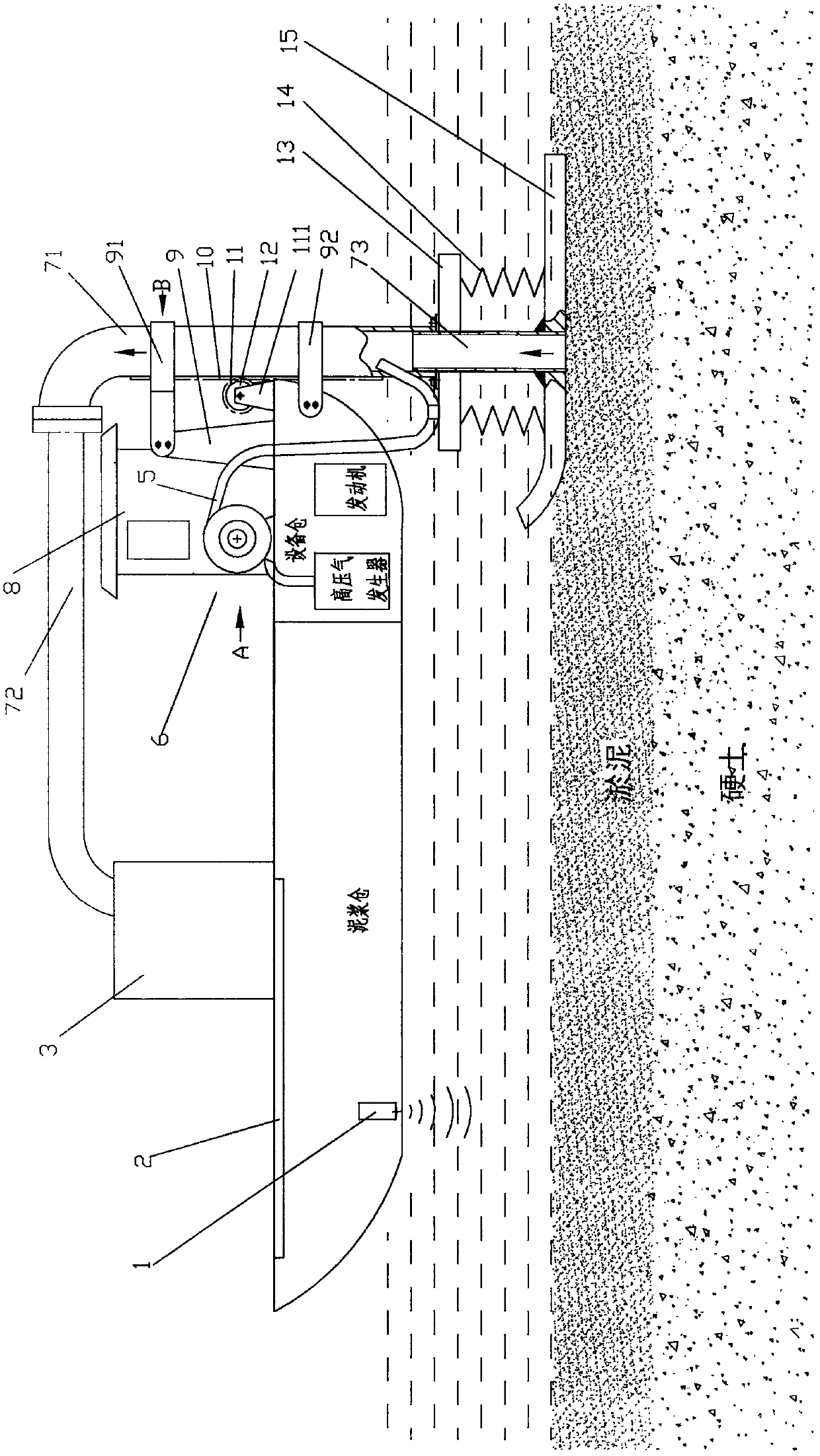

[0025] refer to figure 1 Embodiment one, combining image 3 , Figure 4 , the structure of the underwater river bed is that the upper layer is water, the bottom layer is a hard soil layer, and a soft silt layer is deposited on the hard soil layer. The rear part of the hull of the dredging operation ship is the equipment warehouse, and the high-pressure gas generator and engine used to suck the silt by the jet are installed in the equipment warehouse. The front part of the hull is the mud bin, and the bin mouth 2 of the mud bin is open. shape for easy cleaning and unloading. The upper middle part of the hull is equipped with a gravity energy mud-water separation device 3, and the cockpit 8, the dredging pipe lifting device and the high-pressure air pipe expansion device 6 are located at the rear of the hull; the high-pressure air pipe 5 communicates with the high-pressure gas generator, and the injection end passes through the The high-pressure air pipe expansion device 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com