A method for online replacement of coke oven valve body

A replacement method and valve body technology are used in coke ovens, coke oven parts, and coke oven heating, etc., which can solve the problems of long time consumption, difficult handling of corroded bolts and broken wires, poor safety, etc., so as to achieve simple and economical operation. The effect of manpower and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

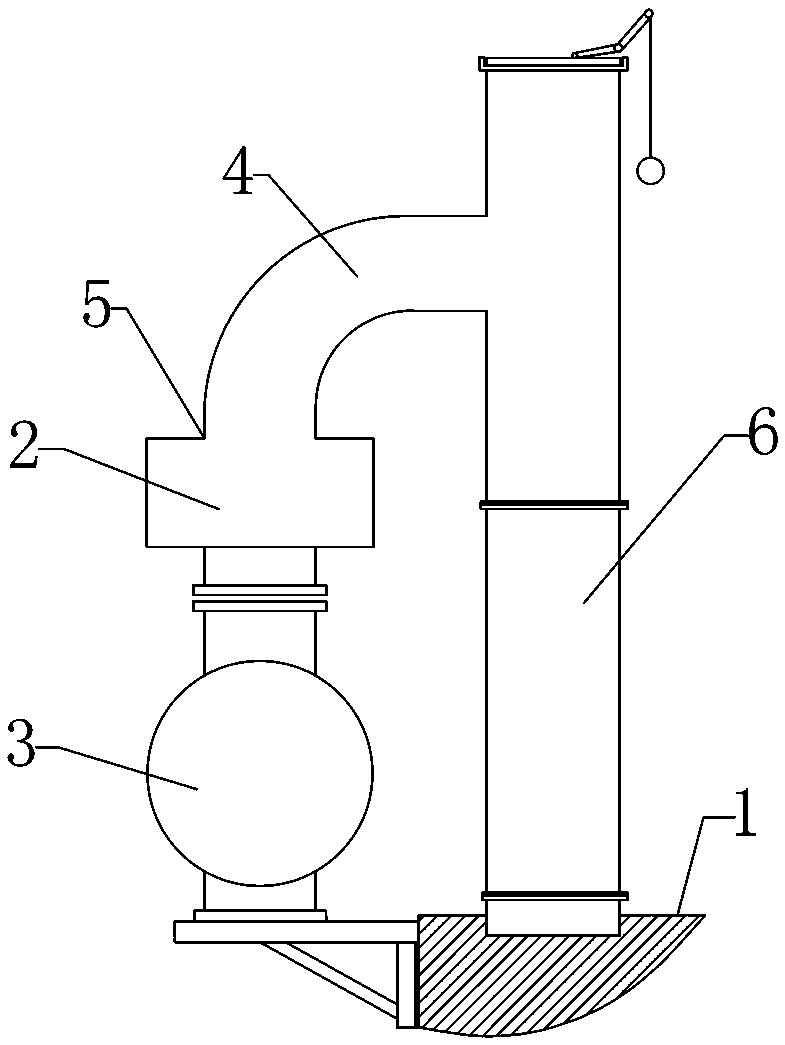

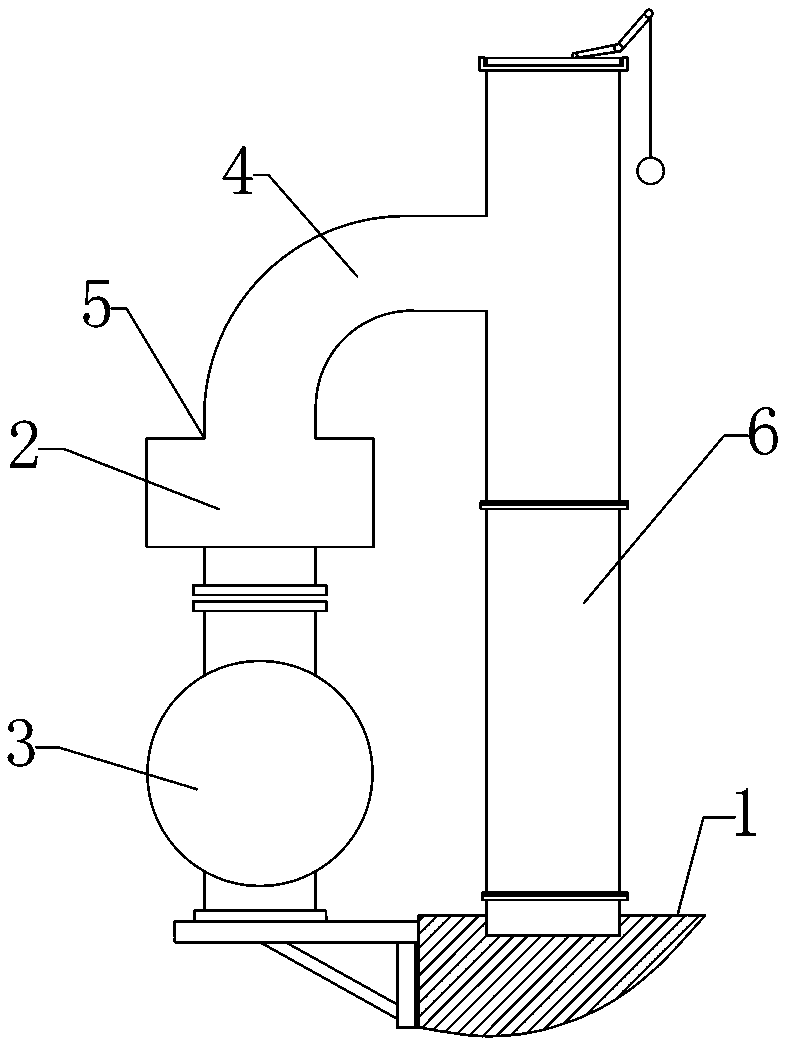

[0033] The coke oven valve body online replacement method of the present invention is suitable for coke ovens with valve bodies installed horizontally (such as figure 1 shown), which can be applied to the replacement of coke oven valve bodies of various sizes. The air pipe adopted in this embodiment is a common welded pipe, and the top of the general coke oven has a spare, which is indispensable during normal maintenance. The blind plate used in this embodiment is a steel plate with a thickness of 10-20mm and a smooth surface, and its size is determined according to the application occasion, as long as it meets the application requirements.

[0034] Before replacing the coke oven valve body, make preparations: lubricate the new valve body turning plate weight, and transport it to the designated position under the coke oven one day in advance; Heat felt, refractory mud, butter and other materials, and prepare the tools needed in the operation process such as gas cutting, gas w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com