Stainless steel band production device with wide-range adjusting function and production method

A technology for stainless steel strips and production equipment, which is applied to the attachment of shearing machines, shearing devices, manufacturing tools, etc. It can solve the problems of inconvenient operation and achieve the effects of simple steps, improved stability, and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

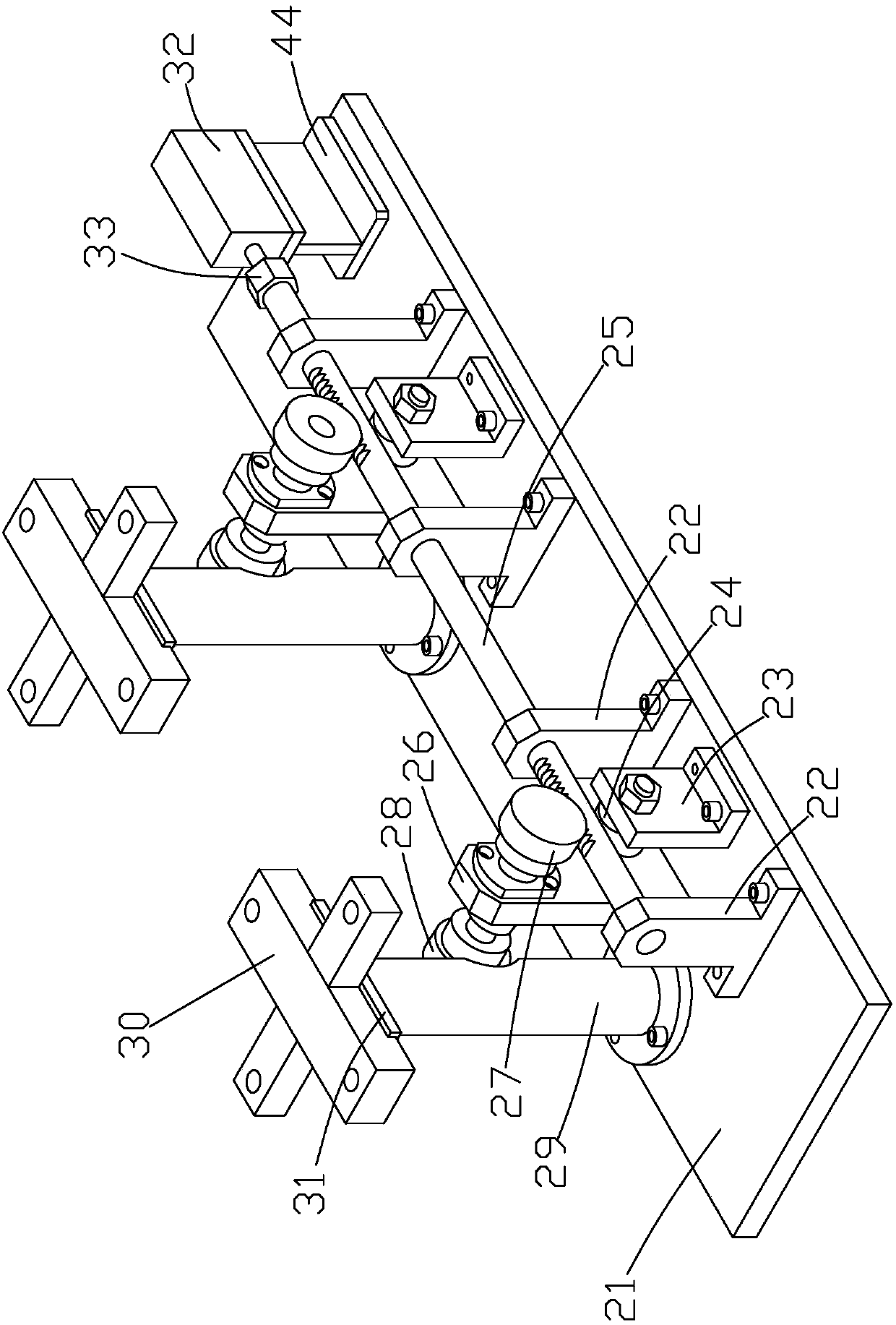

[0034] Such as Figure 1 to Figure 5 As shown, it is a stainless steel strip production device with a width adjustment function of the present invention, including a box body 1, a tension mechanism 2, a processing platform 4, a cutting mechanism 6 and a height adjustment mechanism 7, a tension mechanism 2 and a processing platform 4 All are located above the box body 1, and the tension mechanism 2 is located on the left side of the processing platform 4. The tension mechanism 2 includes a horizontal bar 11, a vertical bar 12, a first guide roller 13, a second guide roller 14, a tension roller 16 and Lifting mechanism, two horizontal rods 11 are arranged in parallel, the vertical rod 12 is vertically connected on the top surface of the horizontal rod 11, the top two sides of the vertical rod 12 are provided with first positioning blocks 15, and the two first positioning blocks on the left side The first guide roller 13 is connected between the blocks 15, the second guide roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com