A kind of separation method of alkylphenol in crude oil

A technology of an alkyl phenol and a separation method, applied in the field of petroleum geological exploration, can solve problems such as analysis troubles, and achieve the effects of being beneficial to elution and enrichment, saving reagents, and having good recovery and repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

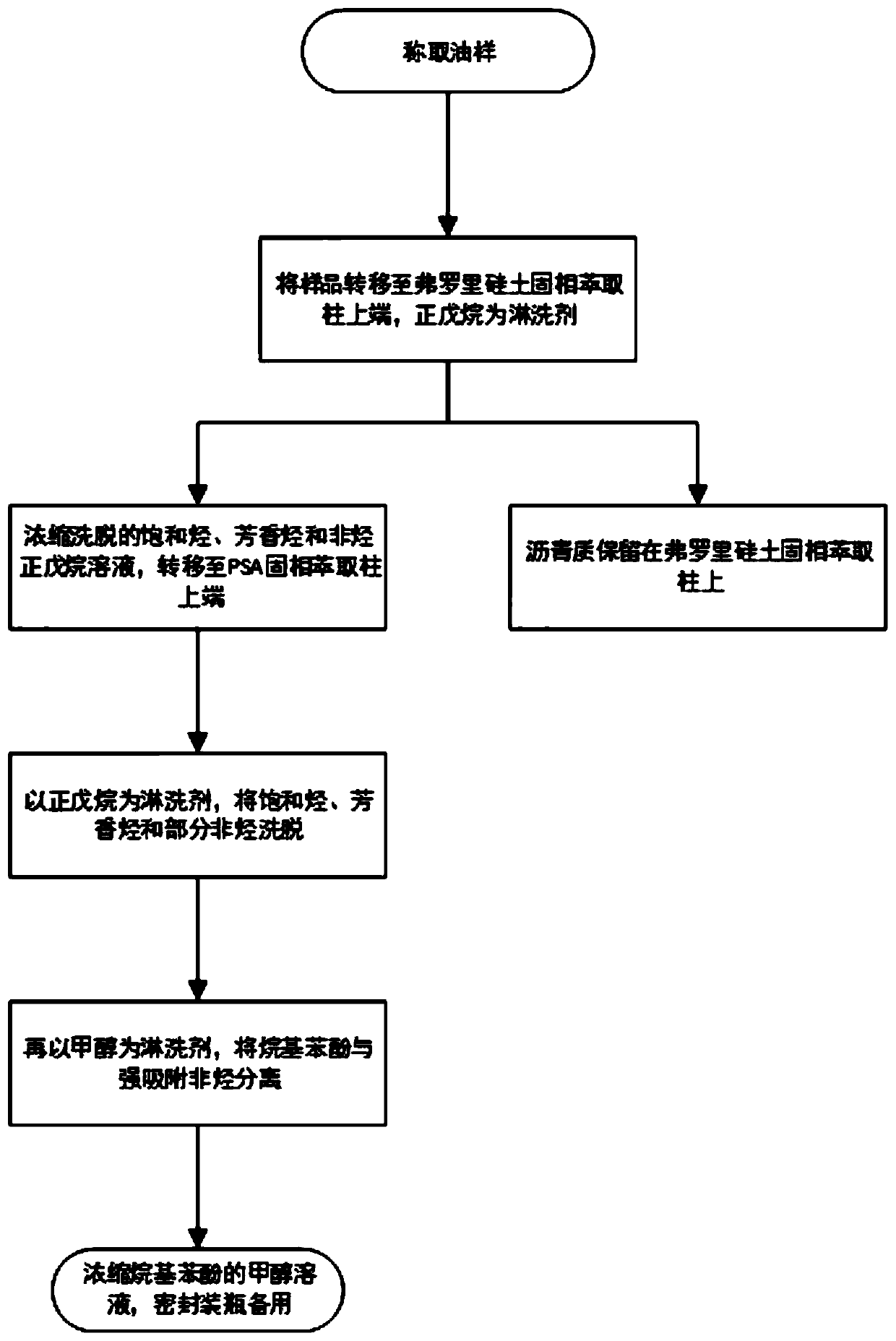

[0044] This embodiment provides a method for separating alkylphenols in crude oil, and the specific process is as follows figure 1 shown, including the following steps:

[0045] Weigh about 50mg of crude oil sample into a 2mL gas chromatography vial;

[0046] Dissolve the oil sample with 100uL dichloromethane and transfer it to the Florisil solid-phase extraction column, then rinse the remaining oil sample in the vial with 100uL dichloromethane and transfer it to the upper end of the Florisil solid-phase extraction column, pay attention When transferring the oil sample, add a small amount of drops several times; leave it for 30 minutes until the dichloromethane evaporates; first rinse the sample on the adsorbent with 0.5mL n-pentane, then rinse it with 4.5mL n-pentane, and collect the eluate ;

[0047] Concentrate the eluent to 0.5 mL under nitrogen blowing at room temperature, transfer the concentrated solution to an N-propylethylenediamine solid-phase extraction column, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com