Piglet nursing bed feeding mechanism

A technology for nursery beds and piglets, applied in food science, food preservation, animal feeding devices, etc., can solve problems such as waste of feed, high labor intensity, and difficult cleaning of feeding troughs, and achieve increased comfort, safety, and automation High, high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

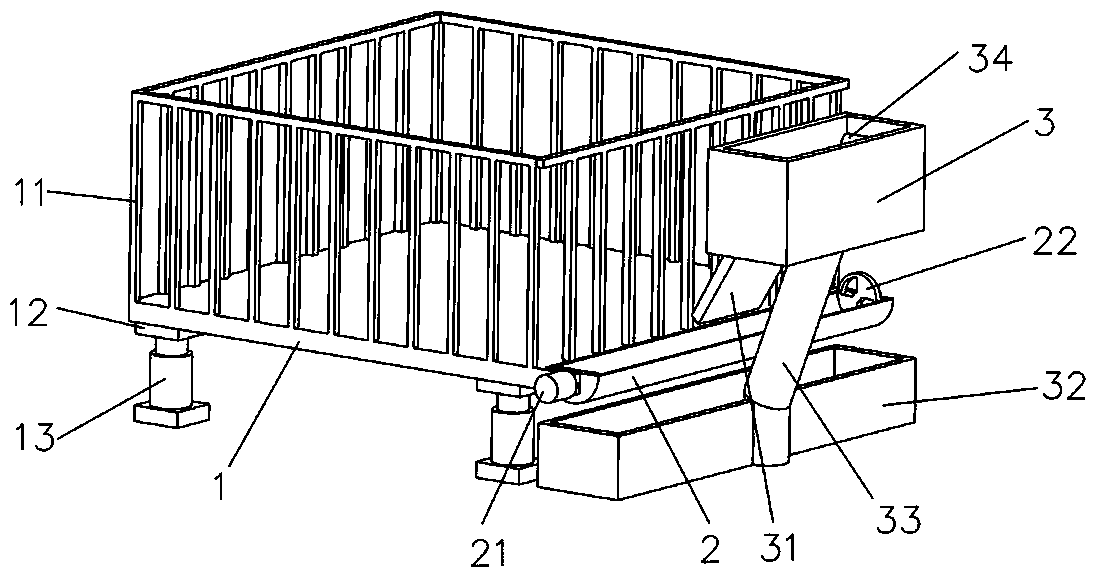

[0026] Such as figure 1 The piglet nursery bed feeding mechanism shown includes a square base plate 1, longitudinal railings 11 surrounding the base plate 1 on all sides, plate-shaped pressure sensors 12 are provided at the bottom four corners of the base plate 1, and a feeding device is provided on one side of the base plate 1. The feeding device comprises a rotatable feeding trough 2, an overturning motor 21 connected to one end of the feeding trough 2, a grain tank 3 installed on the top of the feeding trough, and the grain tank 3 is provided with a grain trough 31 with a rectangular section, and the grain trough 31 extends to Above the feeding trough 2 , a control module is arranged at the bottom of the base plate 1 , the input end of the control module is connected to the pressure sensor 12 , and the output end is connected to the turning motor 21 and the grain tank 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com