A tilting plate adjustment mechanism based on web rotary printing press

A technology of adjusting mechanism and inclined plate, applied in rotary printing machine, printing machine, printing, etc., can solve the problems of time-consuming and laborious, adjustment accuracy difference, etc., to save cost, reduce waste, and improve printing work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further explained in detail below in conjunction with the accompanying drawings.

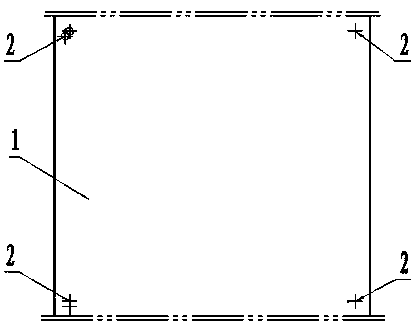

[0034] figure 1 It is a schematic diagram of multi-color overprint oblique (diagonal direction) overprint error. When the web rotary printing machine is in multi-color printing, if there is an error in print 1 figure 1 When there is a small amount of oblique overprint error as shown, the oblique overprint error can be eliminated or reduced by adjusting the slant pull plate adjustment mechanism of the present invention, so that it can be quickly registered.

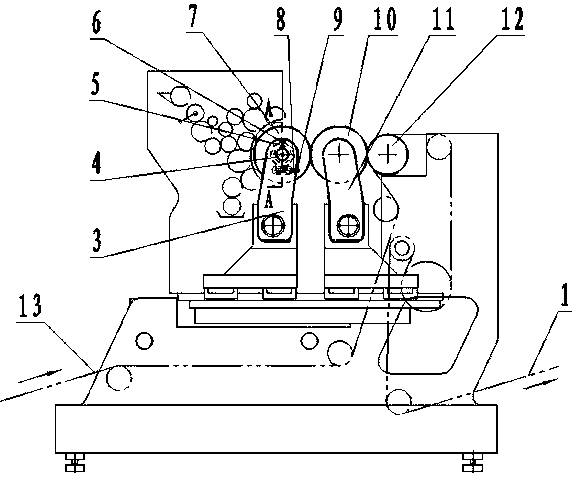

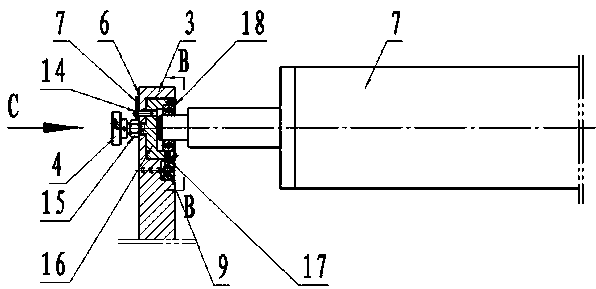

[0035] figure 2 It is a diagram of the working position of the inclined pull plate adjustment mechanism of the present invention on the web rotary printing machine. The printing plate cylinder 7 (including the printing plate), the rubber cylinder 10 (including the rubber), and the impression cylinder 12 are arranged sequentially on the web rotary printing machine. The rubber cylinder 10 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com