A Finite Element Model Establishment Method of Chemically Tempered Glass Considering Residual Stress

A technology of chemical tempered glass and model building, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as inability to calculate, inaccurate calculation results, large models, etc., to reduce the probability of non-convergence, The effect of reducing loading time and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

[0042] Such as Figure 8 As shown, a method for establishing a chemically tempered glass finite element model considering residual stress, including steps:

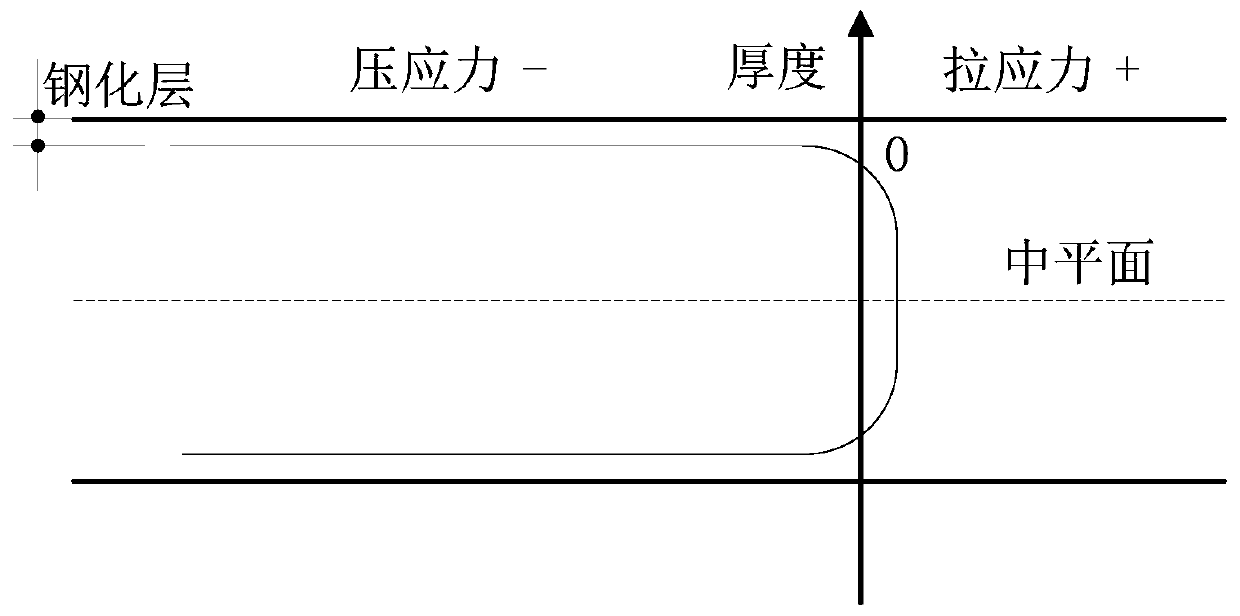

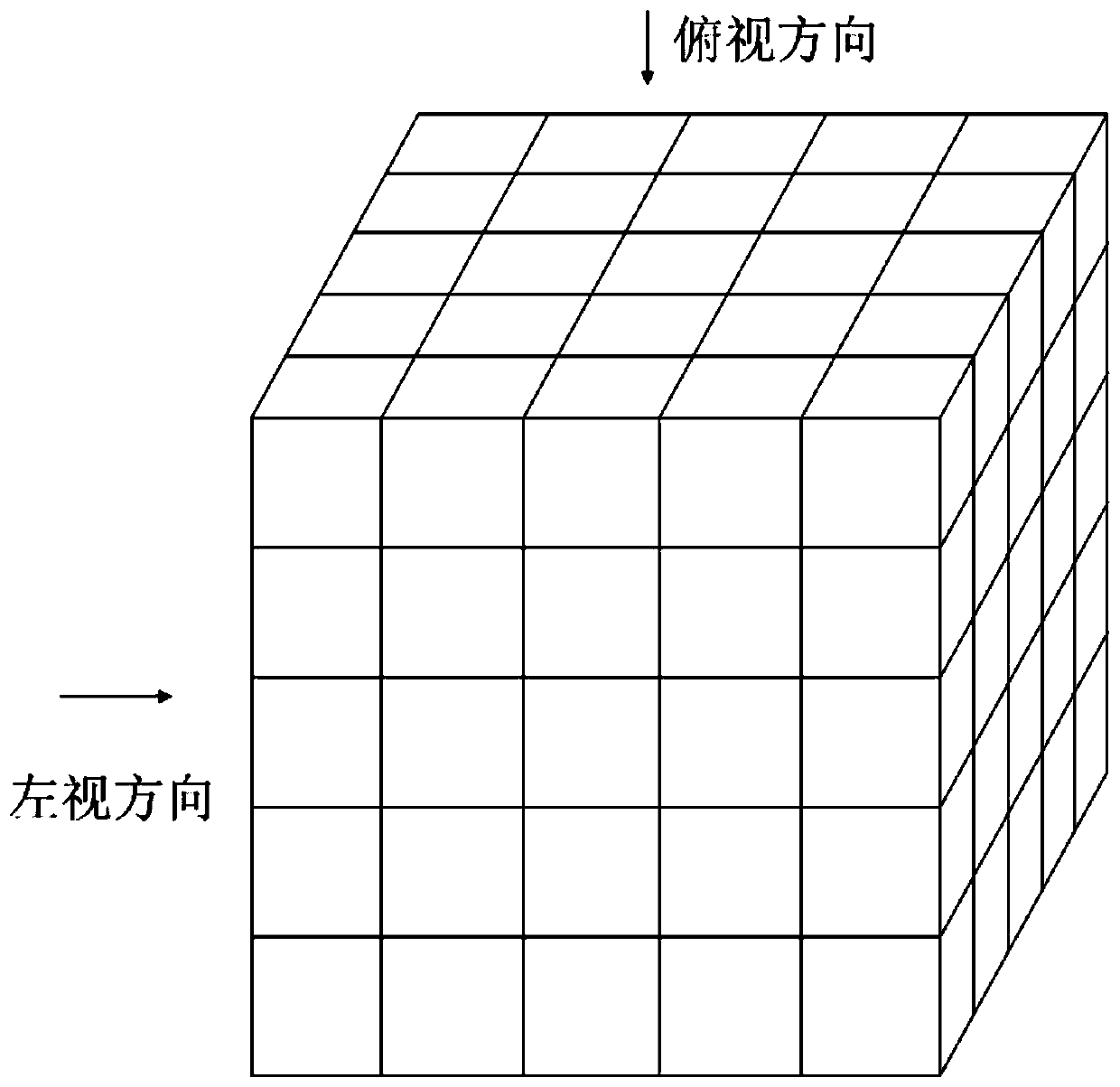

[0043] 1) Establish a tempered glass geometric model in 3D drawing software, import the geometric model into Hypermesh, use shell elements and hexahedron solid elements to divide the mesh, set material parameters and tie contact, and obtain a finite element model of chemically tempered glass without initial stress;

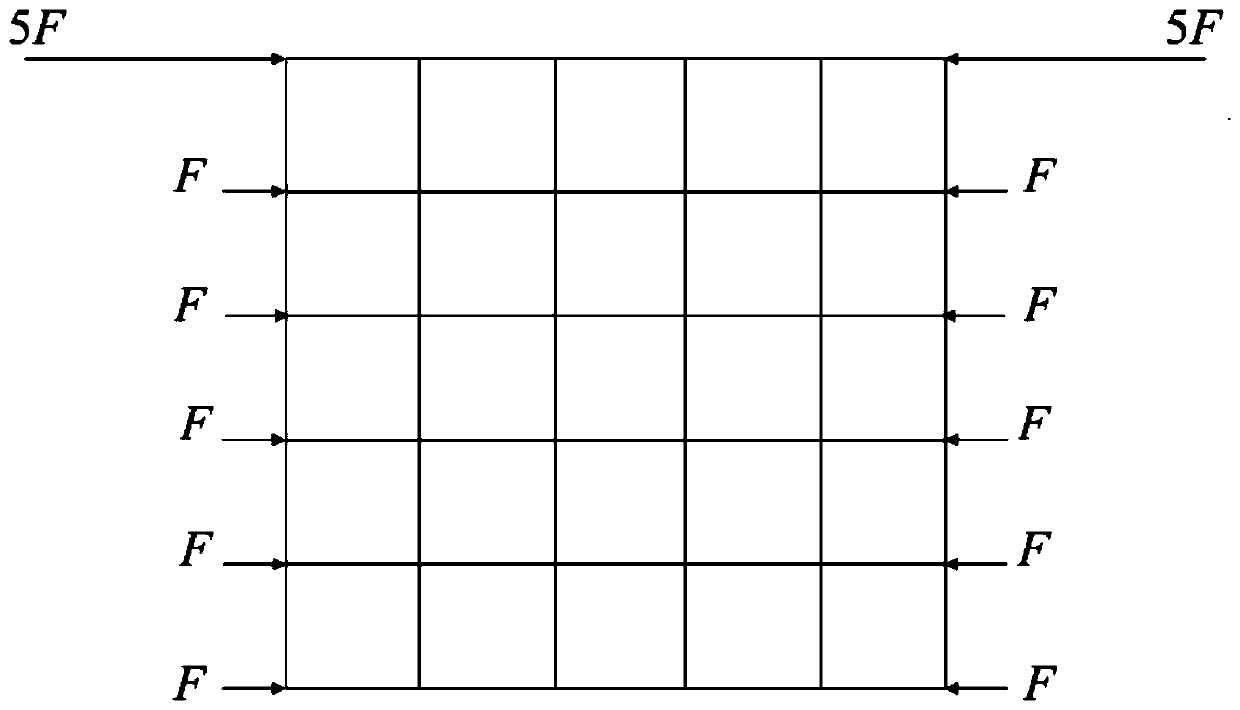

[0044] 2) Establish the equivalent model of the shell element, load the shell element model, output the stress, and then correct the equivalent model load to F c , reload, outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com