Optical-principle based dust sensor with dust prevention function

A dust sensor, optical principle technology, applied in scientific instruments, measuring devices, suspension and porous material analysis, etc., can solve the problems of poor contact, easy to rust, easy to enter the wire interface dust, etc., to extend service life, reduce The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

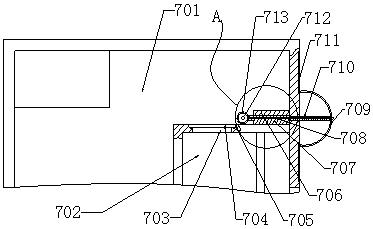

[0024] see Figure 1-Figure 5 , the present invention provides a technical solution: an optical principle dust sensor with the function of preventing dust from entering, including an upper casing 1, a lower casing 2, an induced fan 3, an air inlet 4, a wire interface 5, an interface protection assembly 6, Internal dust-proof component 7 and air outlet 8, the upper case 1 is installed on the upper end of the lower case 2, the air inlet 4 is opened on the upper surface of the upper case 1, the induced fan 3 is assembled inside the air inlet 4, and the wire interface 5 is opened on the upper case On the right end of the body 1, the interface protection component 6 is set at the position of the wire interface 5, and the interface protection component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com