Fixed-wing unmanned aerial vehicle outer wing structure and manufacturing method thereof

A technology of external wing and fixed wing, applied in the field of unmanned aerial vehicles, can solve the problems of complex processing and assembly, large number of parts, high manufacturing cost, etc., and achieve the effect of low manufacturing cost, high surface quality and light structure weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

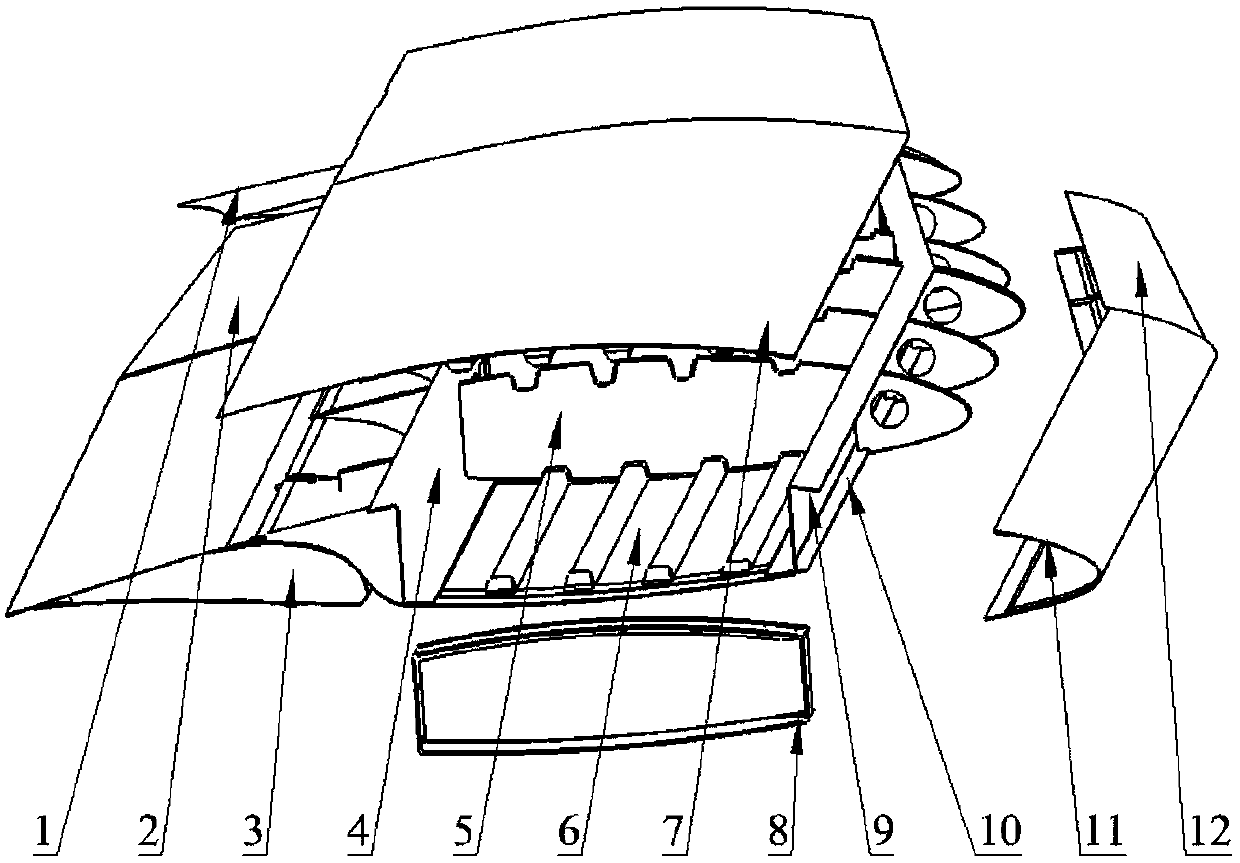

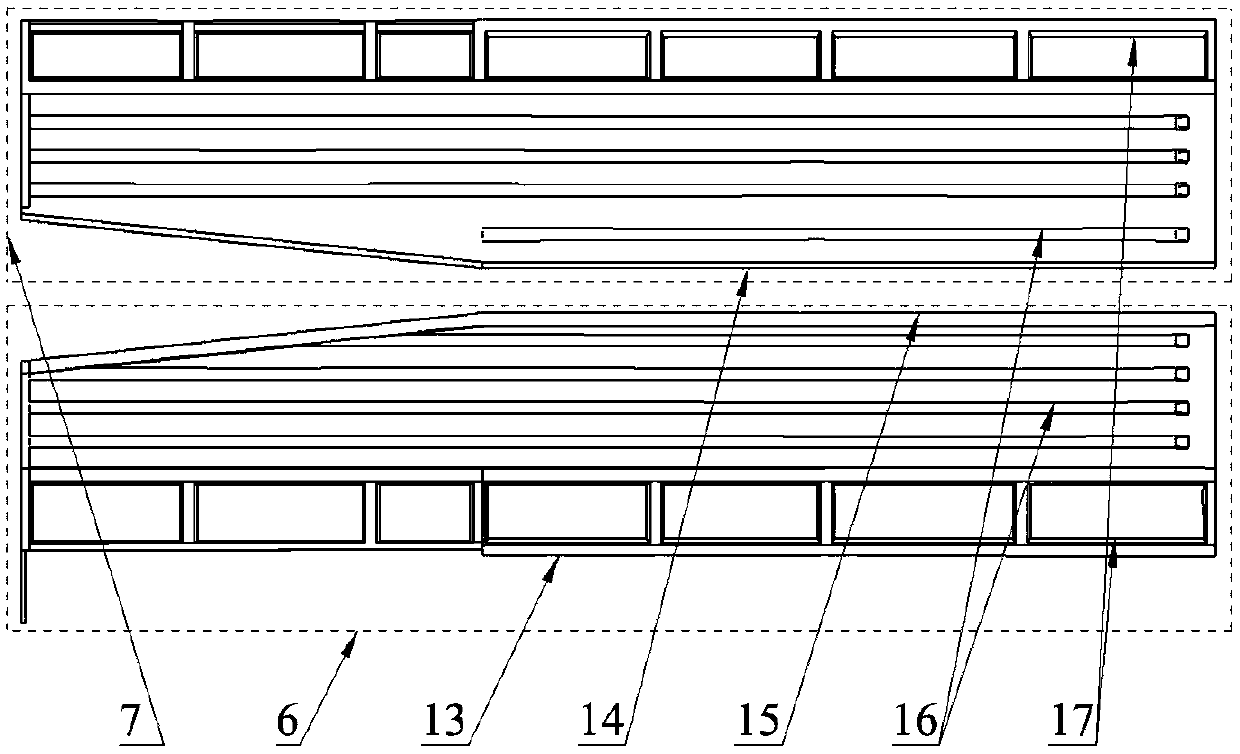

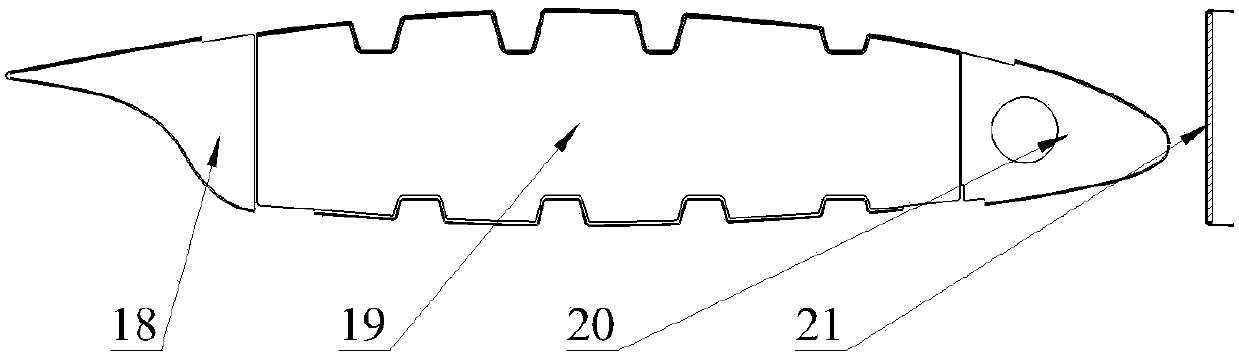

[0025] see Figure 1-Figure 3 , a fixed-wing UAV outer wing structure, including a wing box, the rear end of the wing box is connected to the flap 3, the aileron 2, and the winglet 1 in turn from the inside to the outside, and the front end of the wing box is connected from the inside to the outside. The front edge inner section 11 and the front edge outer section 12 in the shape of a forward bulge are arranged in turn from the inner side to the outer side. It is characterized in that the wing box has an upper wall plate 7, a lower wall plate 6 and a The front beam 9 at the front end of the wall plate 6 is connected to the rear beam 4 at the rear end of the upper wall plate 7 and the lower wall plate 6, and is supported on several ribs 5 extending longitudinally between the upper wall plate 7 and the lower wall plate 6 for connecting The joint 8 of the outer wing and the central wing; the opposite surfaces of the upper wall plate 7 and the lower wall plate 6 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com