Axle assembly applied to variable-gauge bogie

A bogie and axle technology, applied in the field of bogie systems, can solve problems such as low transportation efficiency, and achieve the effect of saving work and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

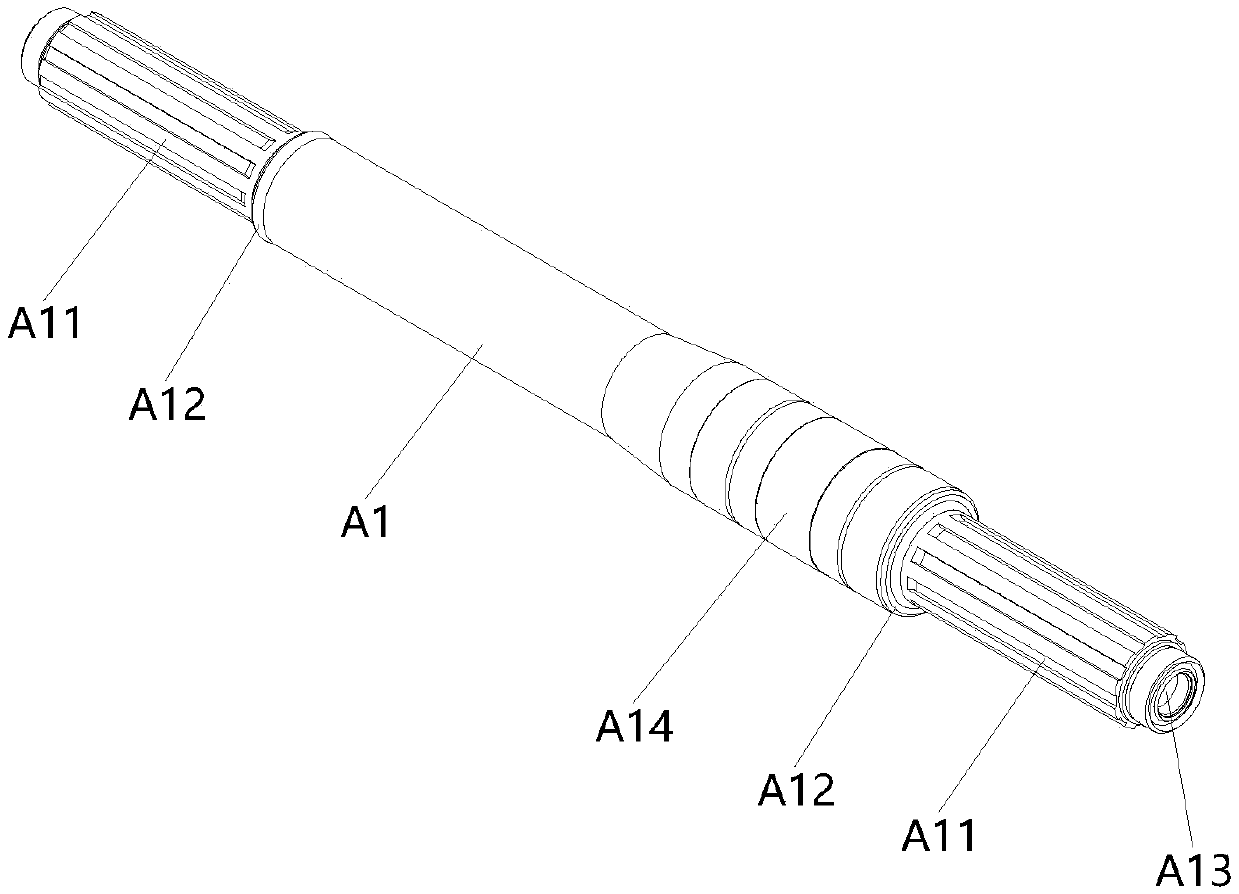

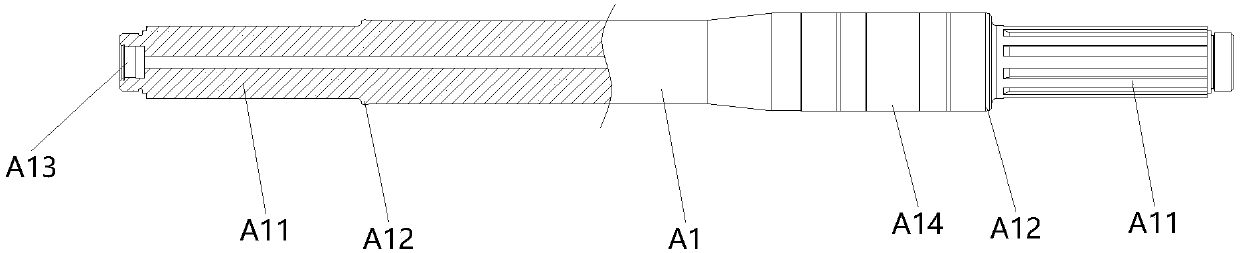

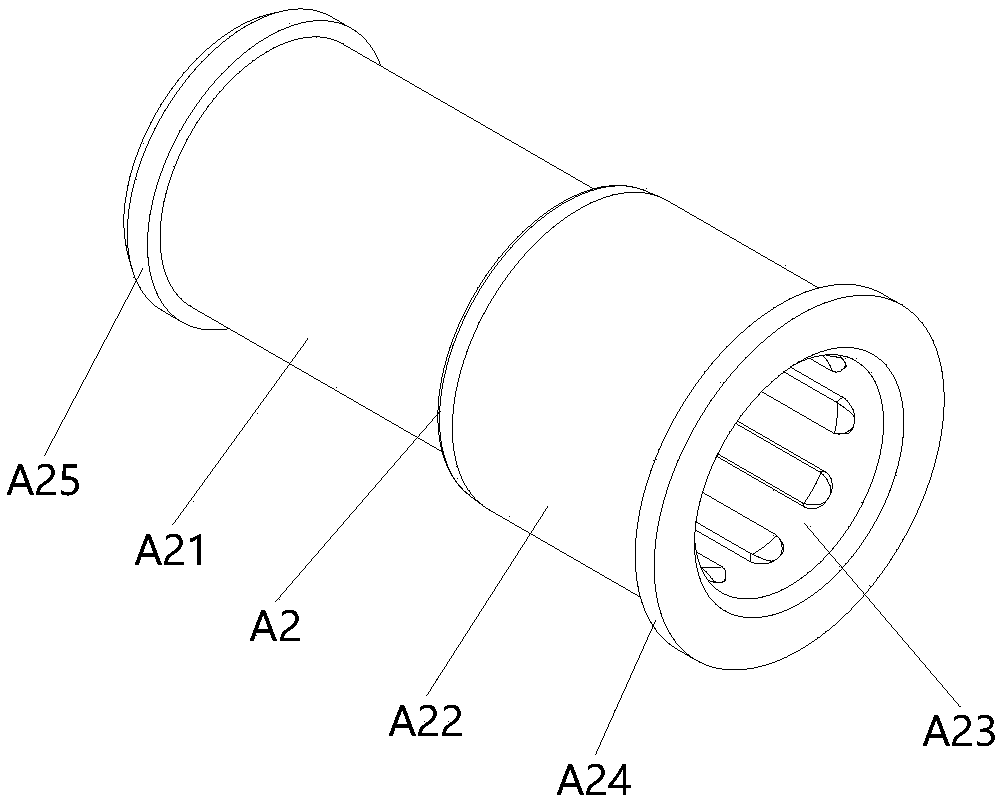

[0030] An axle assembly applied to variable gauge bogies, such as Figure 5 As shown, it includes the axle A1 and the integrated bearing and wheel mounting seat A2; the position from the wheel seat to the end of the axle A1 is the mobile pair connection part A11; the integrated bearing and wheel mounting seat A2 includes the bearing mounting seat A21 connected with each other and the wheel The mounting seat A22 also includes a moving pair joint part A23; the moving pair joint part A23 and the moving pair connecting part A11 form an axial moving pair.

[0031] The integrated mounting seat A2 of the bearing and wheel is a cylindrical body, and the hollow part of the cylindrical body is the joint part A23 of the moving pair, and the joint part A23 of the moving pair is sleeved on the connecting part A11 of the moving pair; The outside of the cylindrical body is the bearing mounting seat A21 and the wheel mounting seat A22. The moving pair joint part A23 is a cylindrical hollow p...

Embodiment 2

[0085] An axle assembly applied to a variable-gauge bogie. Compared with Embodiment 1, the moving pair joint part A23 of this embodiment is a prism-shaped hollow part; the moving pair connecting part A11 is a prism, and the prism The side edge of the body is the same as the axial direction of the main body of the axle A1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com