Magnetically sensitive simulated star loam and its preparation method

A technology for simulating star and magneto-sensitivity, which is applied to the simulation device of space navigation conditions, space navigation equipment, transportation and packaging, etc., to achieve the effect of low cost and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

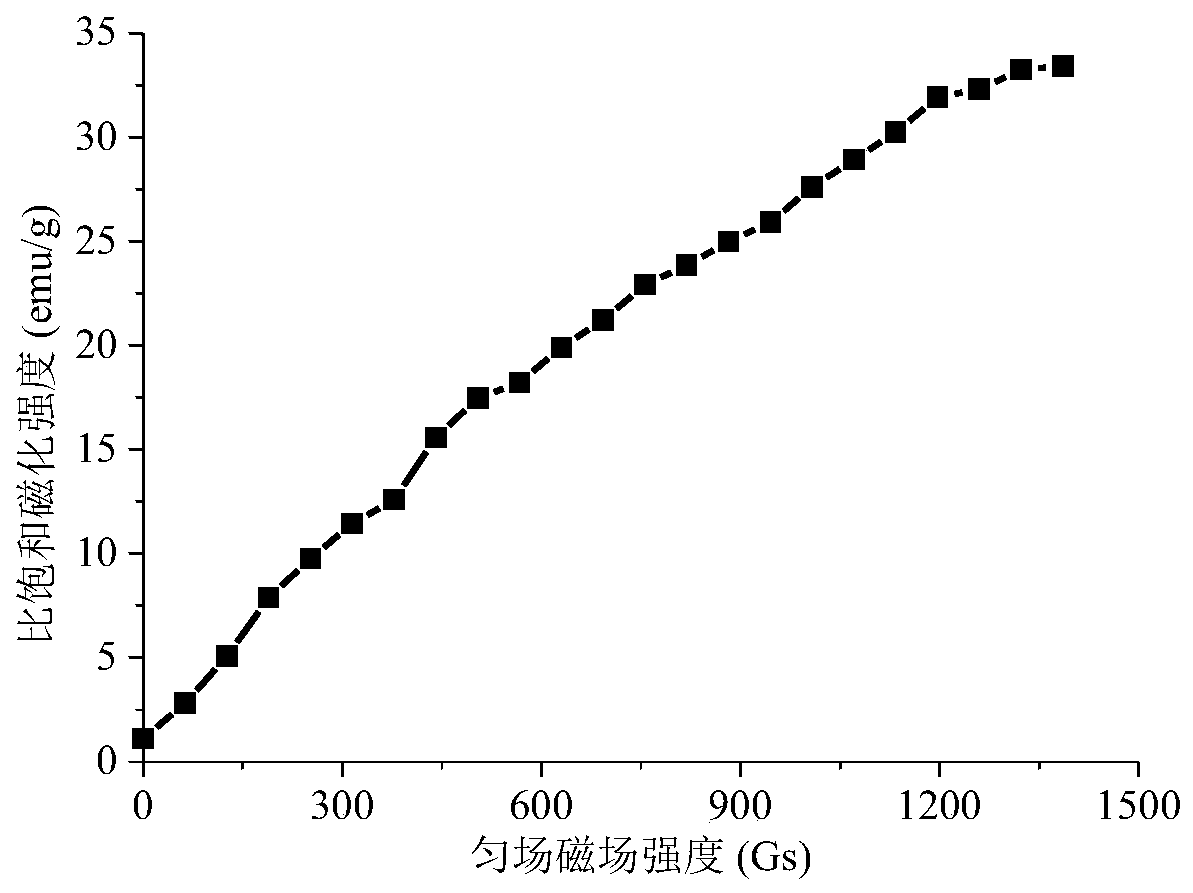

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

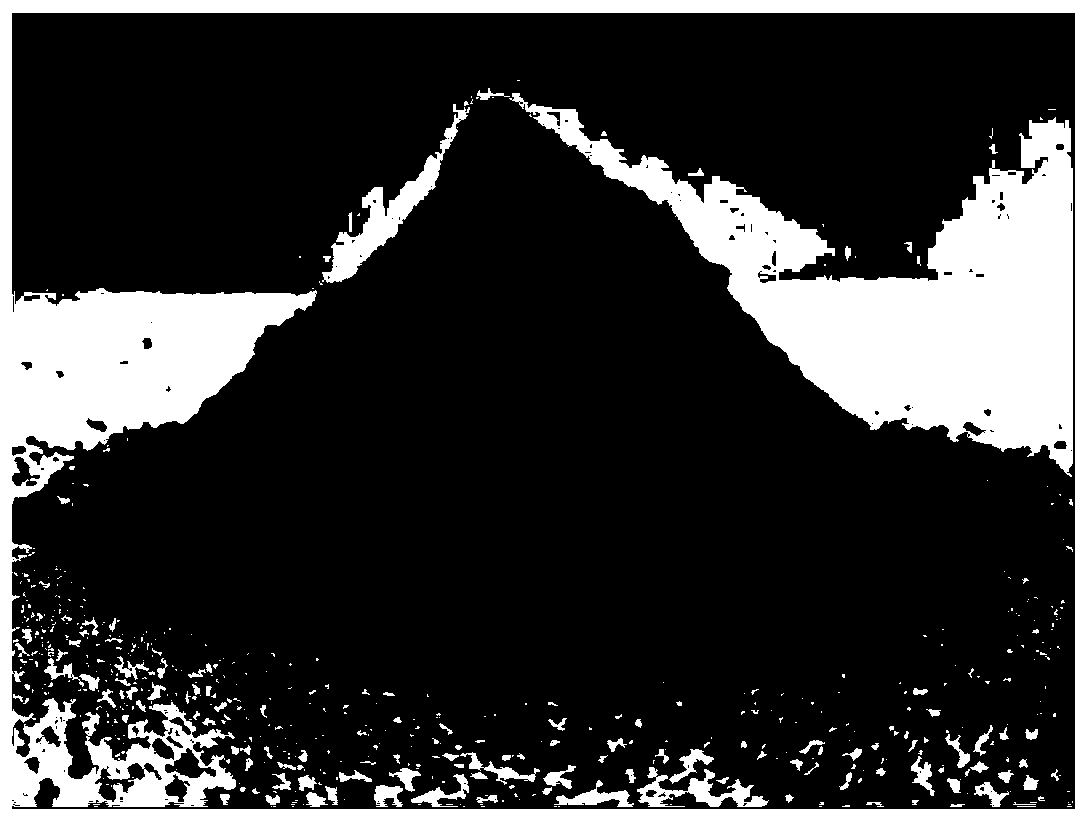

[0037] The preparation method of implementing the above-mentioned magnetic sensitivity simulation star loam is: in the preparation process, the mass ratio of deionized water and cement binder is controlled to be 5:2-5:3, and the mass ratio of cement binder and magnetic admixture is controlled to be 1: 1-1:3; the preparation process includes four stages of mixing, curing, hardening and granulation, and finally forms a magnetically sensitive simulated star loam that can simulate the particle size characteristics, loose particle characteristics and intergranular weak gravity characteristics of in-situ star loam soil ; The specific steps are:

[0038] 1) Take cement binder, magnetic admixture, additive and deionized water according to the mixing ratio;

[0039] 2) Add cement binder and magnetic admixture into the cleaned and dried container, and stir until the two are evenly mixed;

[0040] 3) Add additives to the mixture and continue stirring until uniform;

[0041] 4) Evenly d...

Embodiment 1

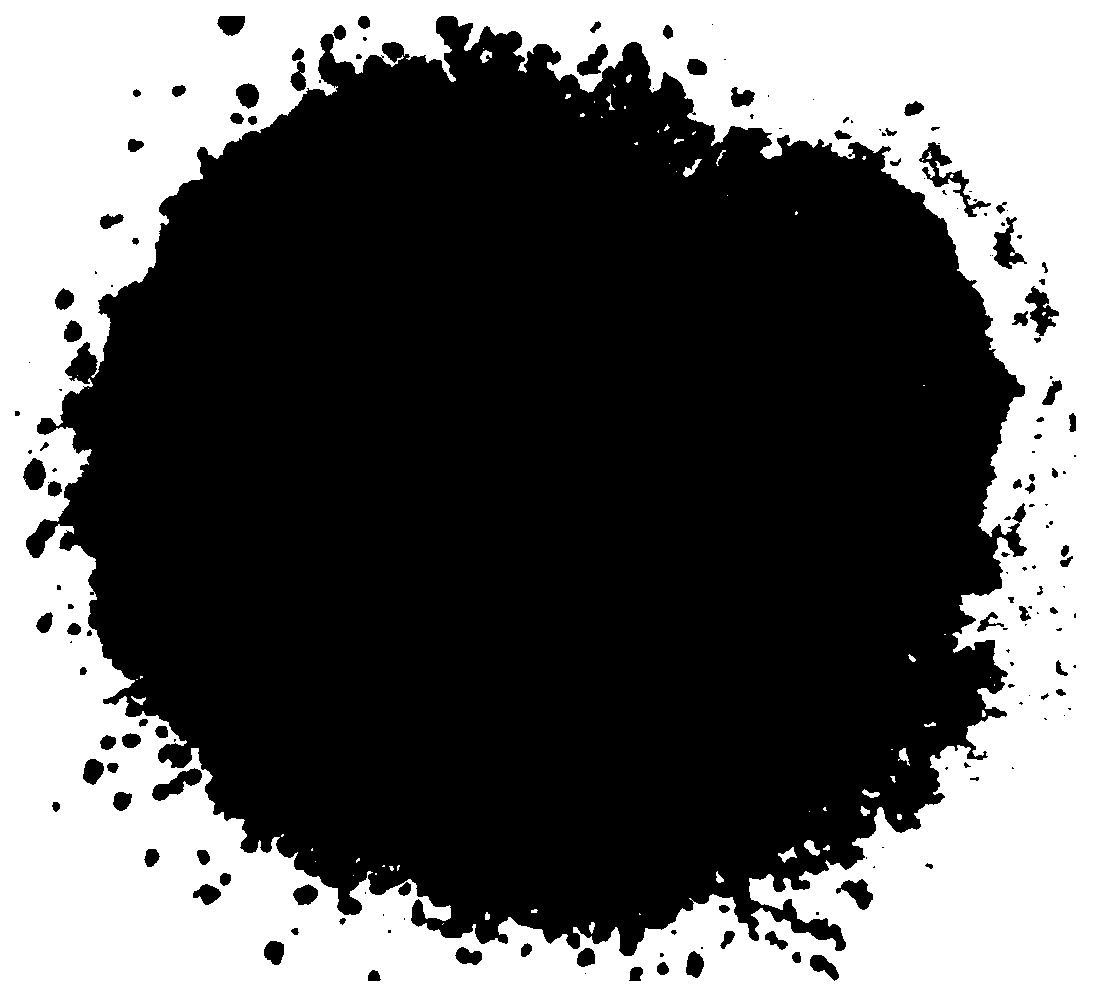

[0048] Example 1. Prepare magnetically sensitive simulated star loam with uniform distribution of particle size in the range of 0.25-0.50 mm.

[0049] 1) Take by weight 100 parts of cement binder, 300 parts of magnetic admixture, 5 parts of additives, and 50 parts of deionized water;

[0050] 2) Add 100 parts of cement binder and 300 parts of magnetic admixture into the cleaned and dried container, and stir until the two are evenly mixed;

[0051] 3) Add 5 parts of additives and continue stirring until uniform;

[0052]4) Add 50 parts of deionized water 5 times, 10 parts each time, stir the mixture until it is evenly added, then continue to add the next 10 parts of deionized water, stir until all 50 parts of deionized water are added, and continue stirring 20 minutes;

[0053] 5) Divide a total of 455 parts of the well-stirred mixture into 5 equal parts and pour them into the mold one by one. Pour 91 parts each time. After pouring, vibrate for 10 minutes. After all the air b...

Embodiment 2

[0066] Example 2. Prepare magnetically sensitive simulated star loam with a linearly decreasing distribution of particle diameters ranging from 1.00 to 2.00 mm.

[0067] 1) Weigh 100 parts of cement binder, 200 parts of magnetic admixture, 5 parts of additive, and 60 parts of deionized water according to the mass ratio;

[0068] 2) Add 100 parts of cement binder and 200 parts of magnetic admixture into the cleaned and dried container, and stir until the two are evenly mixed;

[0069] 3) Add 5 parts of additives and continue stirring until uniform;

[0070] 4) Add 60 parts of deionized water 5 times, 12 parts each time, stir the mixture until it is evenly added, then continue to add the next 10 parts of deionized water, stir until all 60 parts of deionized water are added, and continue stirring 20 minutes;

[0071] 5) Divide a total of 365 parts of the well-stirred mixture into 5 equal parts and pour them into the mold one by one, pouring 73 parts each time, vibrate for 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com