Safety device for prefilled syringes, comprising Anti-triggering mechanism

A technology for safety devices and syringes, applied in the direction of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of damaged syringes, increased production costs, and unavailability, and achieve the effect of rapid installation and safe safety devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

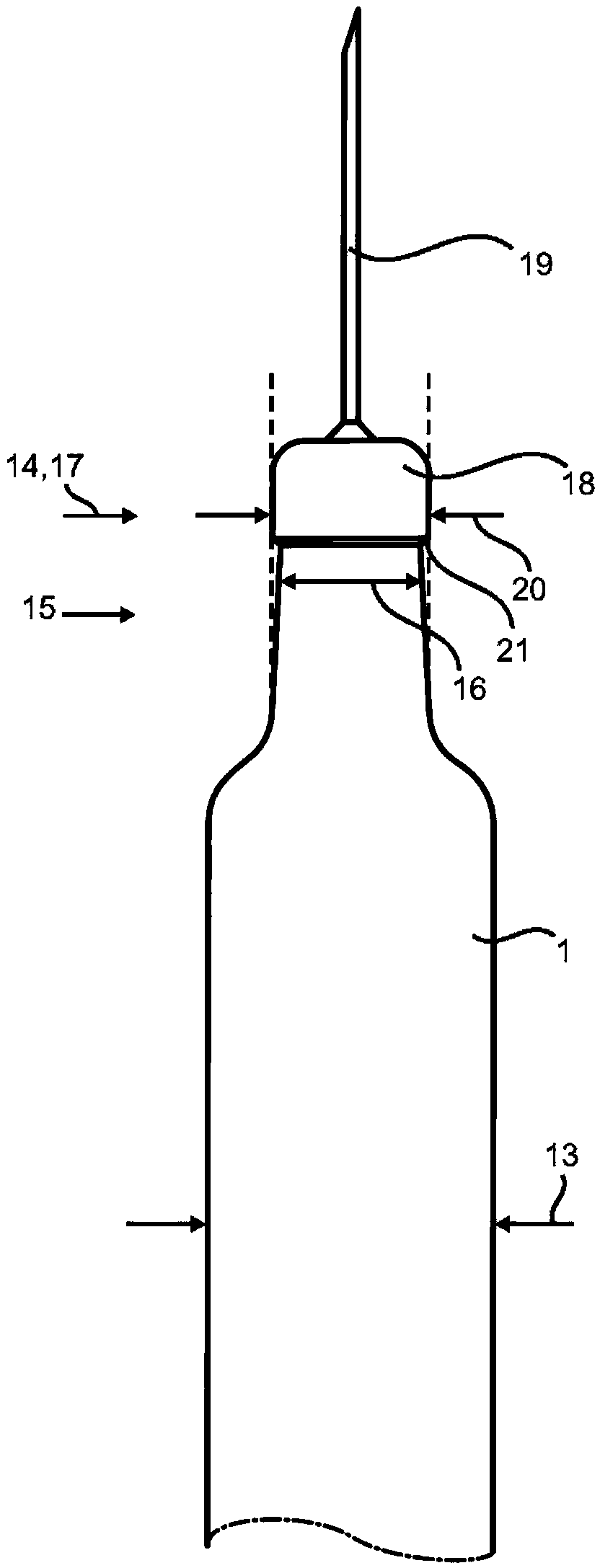

[0039] figure 1 A possible syringe body 1 forming the basis of the invention is shown. Commercially available syringe bodies 1 are substantially cylindrical like the syringe body 1 in this embodiment and have a predetermined or predeterminable diameter 13 . In this case, the syringe body 1 also comprises at its distal end 14 a narrower region 15 which is also substantially cylindrical. In this case, however, the narrower region 15 has a frustoconical shape, the frustoconical narrower region 15 having a diameter 16 at the cap (not shown), ie at the end 17 of the narrower region 15, The diameter 16 of the narrower region 15 is smaller than the diameter 13 of the syringe body 1 .

[0040] Furthermore, in this case a needle hub 18 with a piercing element 19 , in this case a needle 19 , is arranged at the distal end 17 of the narrower region 15 , said needle hub 18 having a larger diameter 20 than the narrower region 15 has a diameter 16 but is smaller than the diameter 13 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com