Hook digging rock arm small arm with material filling mechanism

A technology for digging rocks and materials with hooks, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of inconvenient adjustment of the rock arm of the hook, complicated structure of the connection between the forearm and the hook, and high maintenance costs. The effect of affecting work efficiency, simple structure and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

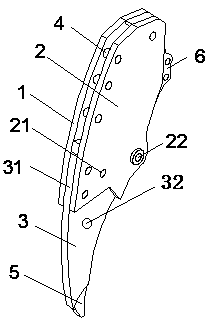

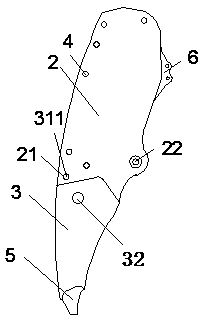

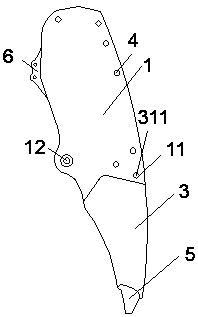

[0035] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 It shows a rock arm forearm with a material filling mechanism, including a left splint 1, a right splint 2 and a digging hook plate 3, the left splint 1 and the right splint 2 are arranged side by side, and the upper part of the digging hook plate 3 is clamped on the left Between the splint 1 and the right splint 2, the hook digging plate 3 is connected with the left splint 1 and the right splint 2 in a detachable manner. The hook digging plate 3 is a hollow structure, and the middle part of the hook digging plate 3 is provided with a filling port 32.

[0036] Existing digging hooks are usually connected to the forearm through the ear plate, so the connection structure is complicated, and both the ear plate and the digging hook are easily damaged. However, the digging hook and the forearm are made into an integrated structure. If the excavated part is damaged, it needs to be replaced a...

specific Embodiment 2

[0037] In this embodiment, on the basis of the specific embodiment 1, a supporting and positioning short post 4 is added, and the left splint 1 and the right splint 2 are connected by one or more supporting and positioning short posts 4 .

[0038] If there is a space between the left splint and the right splint, it is necessary to use the supporting positioning short column for fixing and positioning. Compared with processing with a support plate, the workload is smaller and the processing technology is simpler.

specific Embodiment 3

[0039] This embodiment is based on the specific embodiment 2 to further explain the location of the supporting and positioning stubs 4 . The supporting and positioning stubs 4 are arranged along the edges of the left splint 1 and the right splint 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com