Corrugated wire automatic roll changing and edge sealing equipment and its application method

A corrugated line, automatic technology, used in paper/cardboard containers, packaging, container manufacturing machinery, etc., can solve the problems of potential safety hazards, affecting the production progress, and lack of close contact between the end faces, and achieves a simple and reliable structure that eliminates potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0048] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

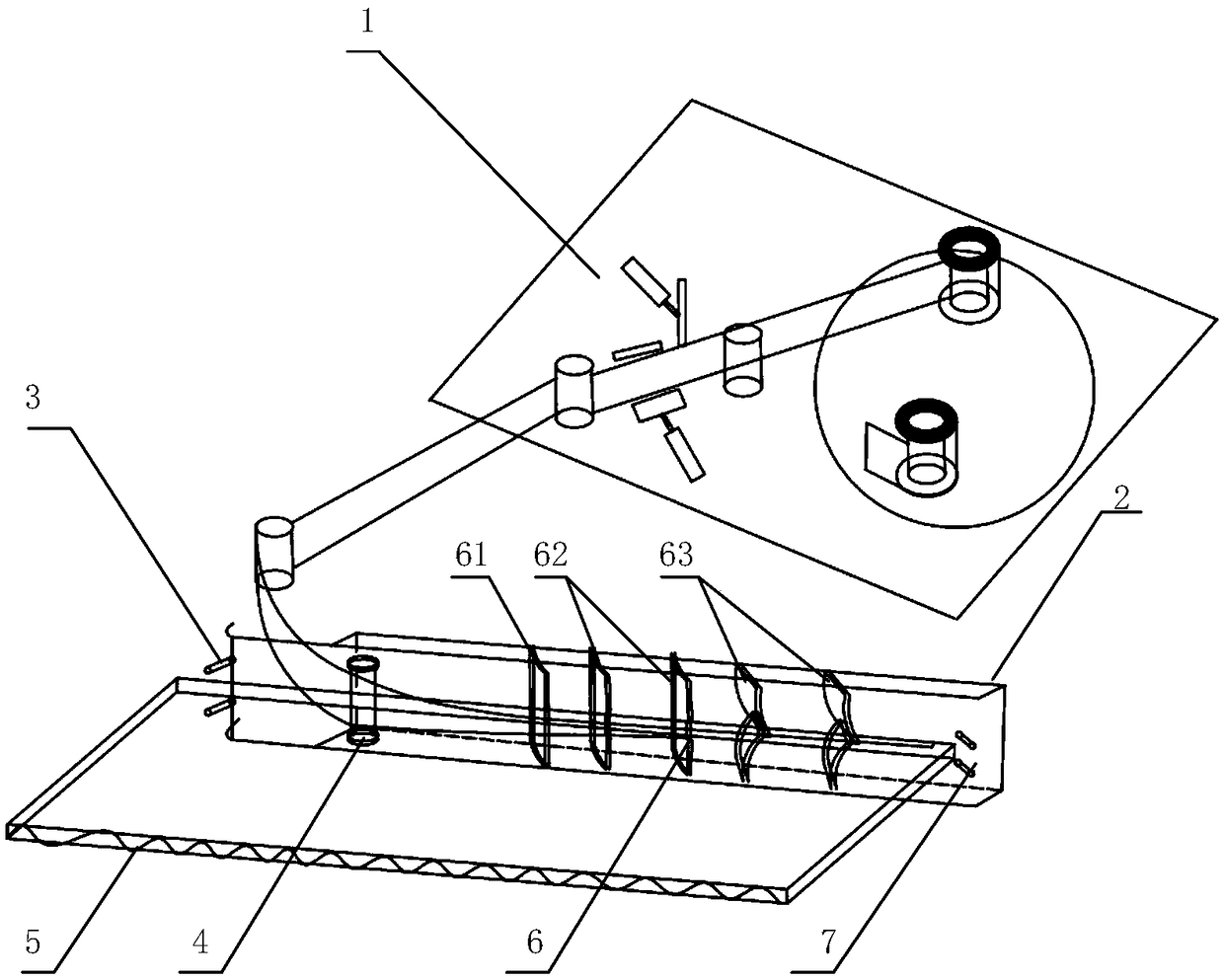

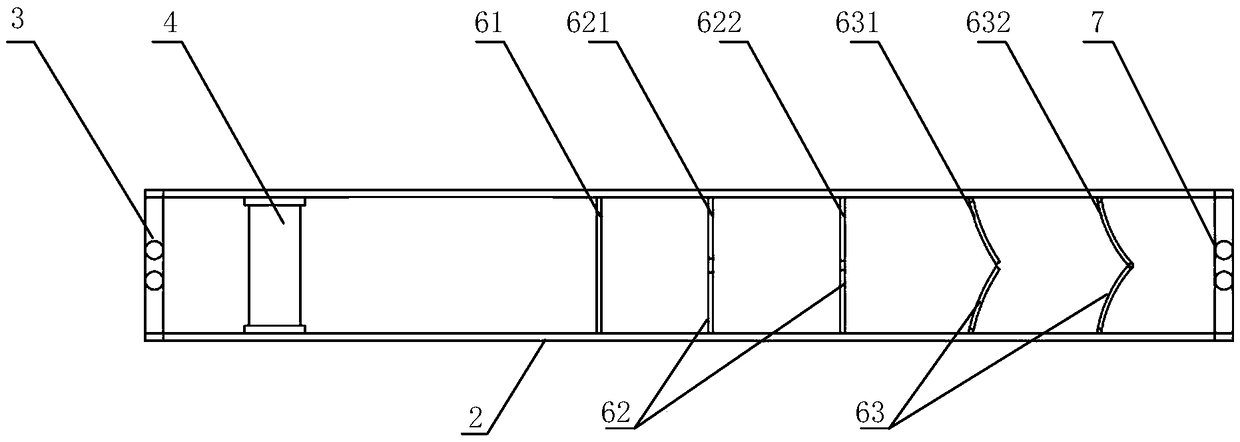

[0049] Figure 1~2 , shows an implementation form according to the present invention, which includes a tape unwinding and changing device 1 and a support 2, and the support 2 is sequentially provided with a first limiting device 3 and a tape guide wheel along the advancing direction of the corrugated cardboard production line 4. Tape turning and pasting device 6 and second limiting device 7;

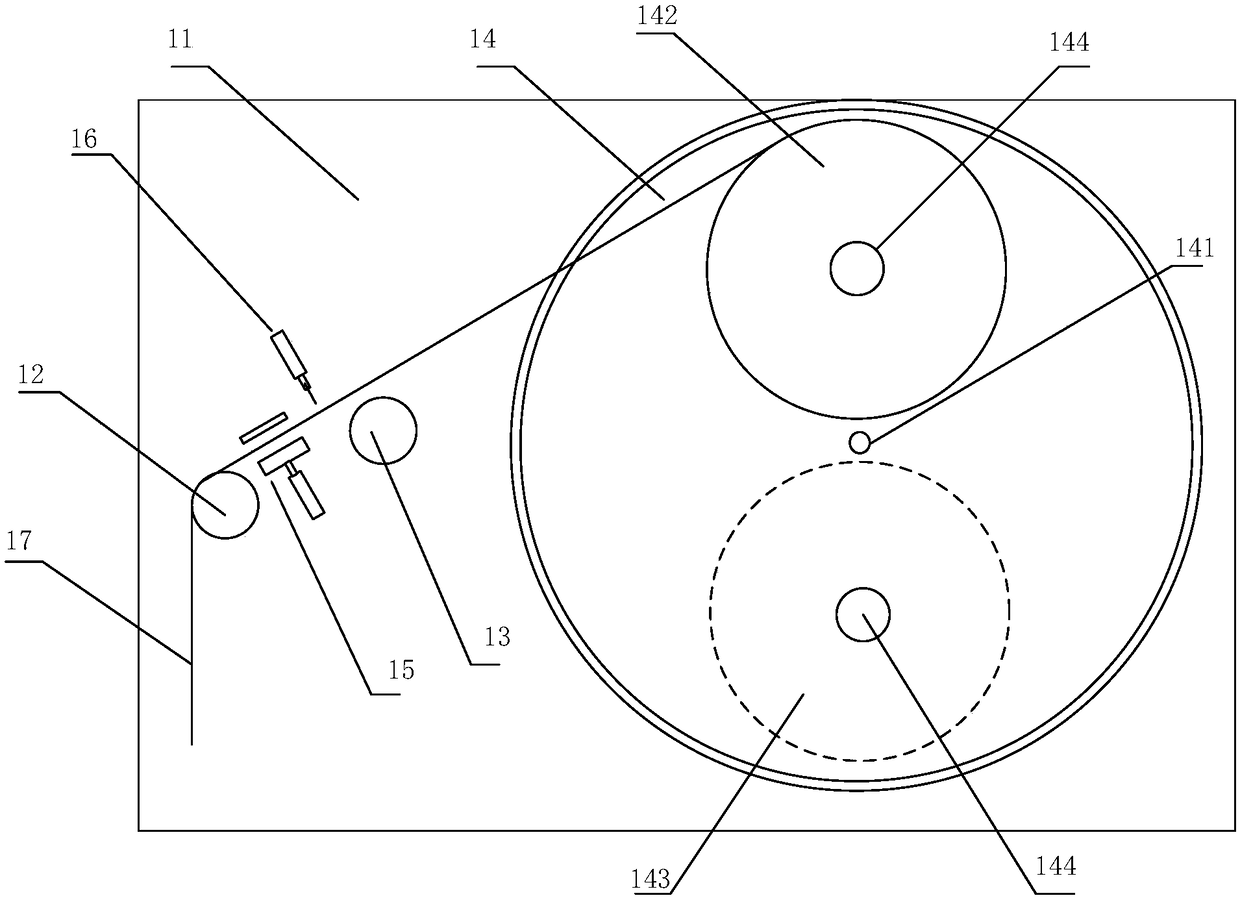

[0050] like Figure 3-4 As shown, the adhesive tape unwinding and rewinding device 1 includes a base 11 on which a first guide wheel 12, a second guide wheel 13 and a roll changing turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com