Transparent soil model test device for simulating tunnel excavation deformation and test method

A model test device and tunnel excavation technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that the deformation characteristics of the model cannot be directly observed, and achieve the effects of small size, reasonable system setting, and convenient test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A transparent soil model test device for simulating tunnel excavation deformation, which is characterized in:

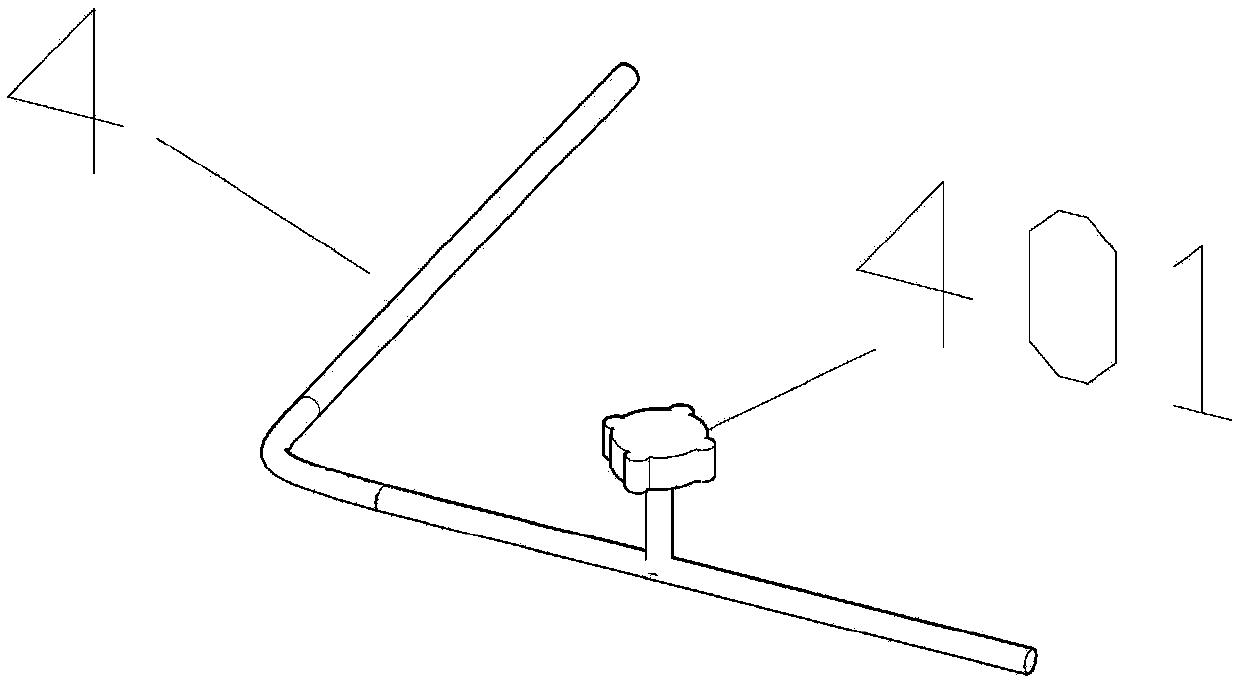

[0044] It mainly includes transparent model box 1, rubber thin-walled round pipe 3, drain pipe 4, industrial camera I5, industrial camera II50, laser transmitter I6, laser transmitter II60 and optical platform 7.

[0045] See figure 1 , The transparent model box 1 is made of plates, and the transparent model box is made of plexiglass. The upper end is open, and the four sides are defined as the front, rear, left, and right sides respectively [the definition It is for the convenience of description to express the positional relationship of the four faces]. The transparent model box 1 is made of organic glass. The left and right side panels and the bottom panel are glued together. The panels on both sides of the circular opening I101 and the circular opening II102 are bolted to the left and right panels and the bottom plate. The panels on both sides can be removed...

Embodiment 2

[0055] This embodiment discloses a test method based on the test device described in embodiment 1, which is characterized in that it includes the following steps:

[0056] 1) Make transparent model box 1, thin-walled rubber cylinder 3 and drain pipe 4 according to the designed size.

[0057] 2) Fill the thin-walled rubber cylinder 3 with water, and place it upside down so that the bottom surface of the opening 301 faces upward.

[0058] 3) Connect the thin-walled rubber cylinder 3 to the drain pipe 4, and do waterproof sealing treatment to the connection.

[0059] 4) Pass the thin-walled rubber cylinder 3 through the opening 101 of the transparent model box 1 and place it in the box body, and do a waterproof sealing treatment on the interface.

[0060] 5) Prepare transparent soil 2 in the transparent model box 1 to the design height. After preparation, let it stand for 24 hours. In the embodiment, the preparation method of the transparent soil 2 is: pour the prepared mixture of white ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com