A Spatial Geometry Calibration Method for Eddy Current Displacement Sensor Array

A displacement sensor and geometric calibration technology, which is applied in the detection field, can solve the problems of no universality, no spatial geometric position calibration, and few methods for spatial geometric calibration of eddy current displacement sensor arrays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

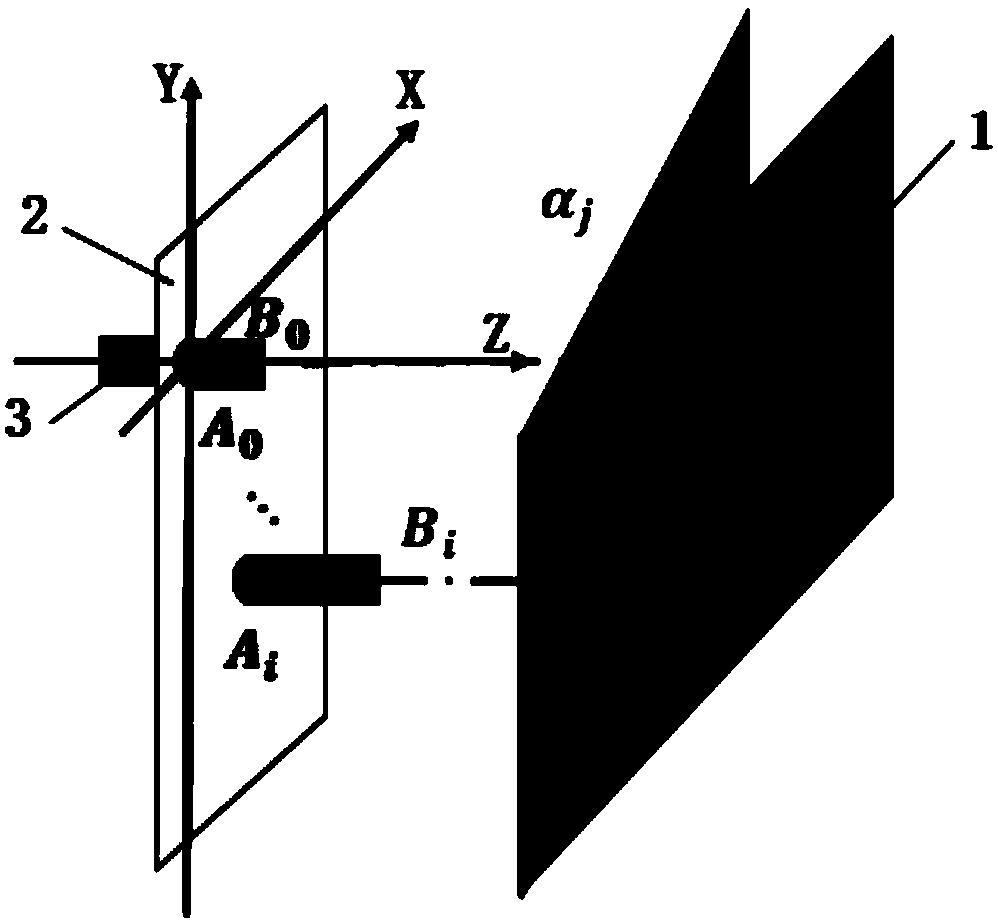

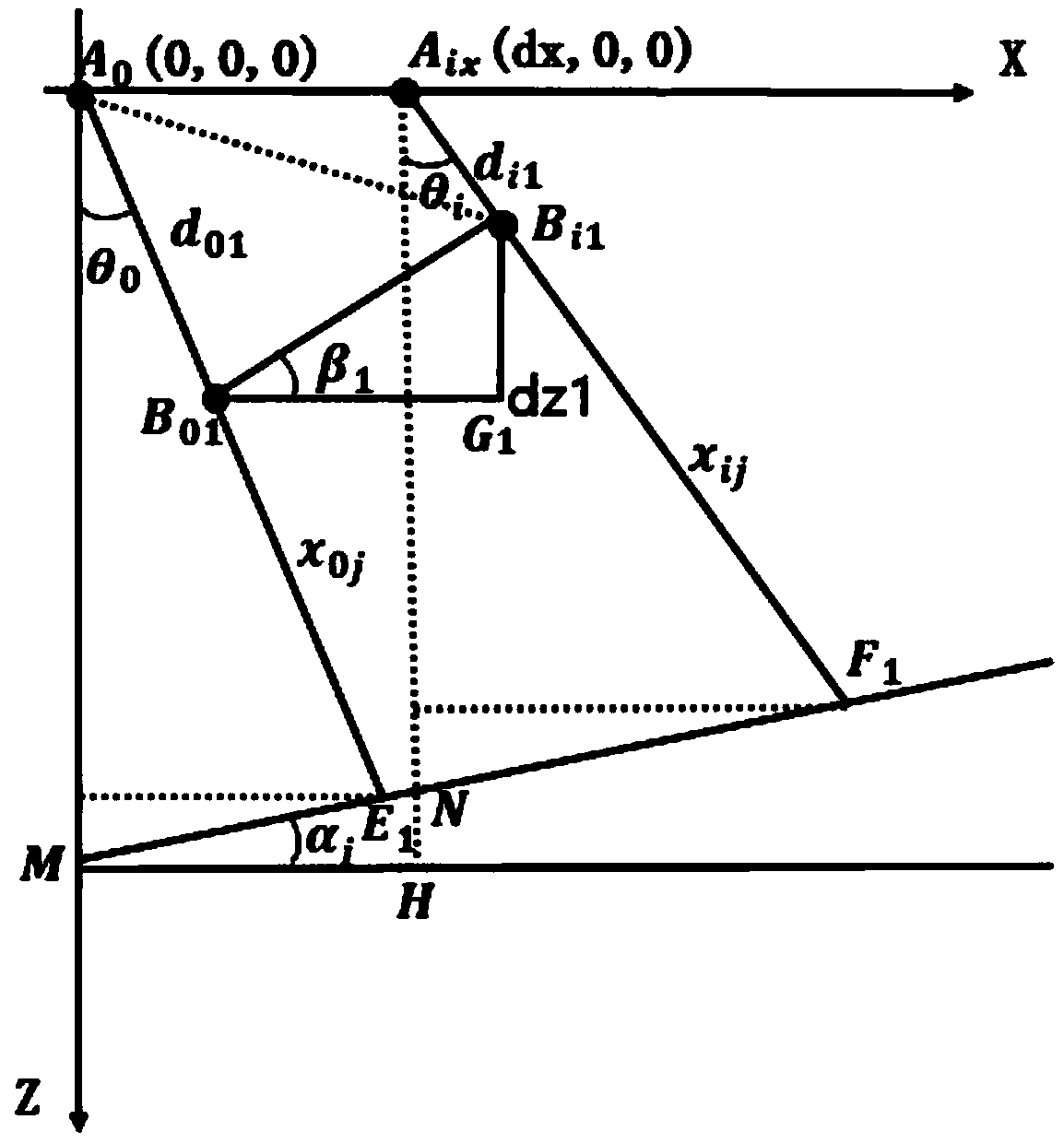

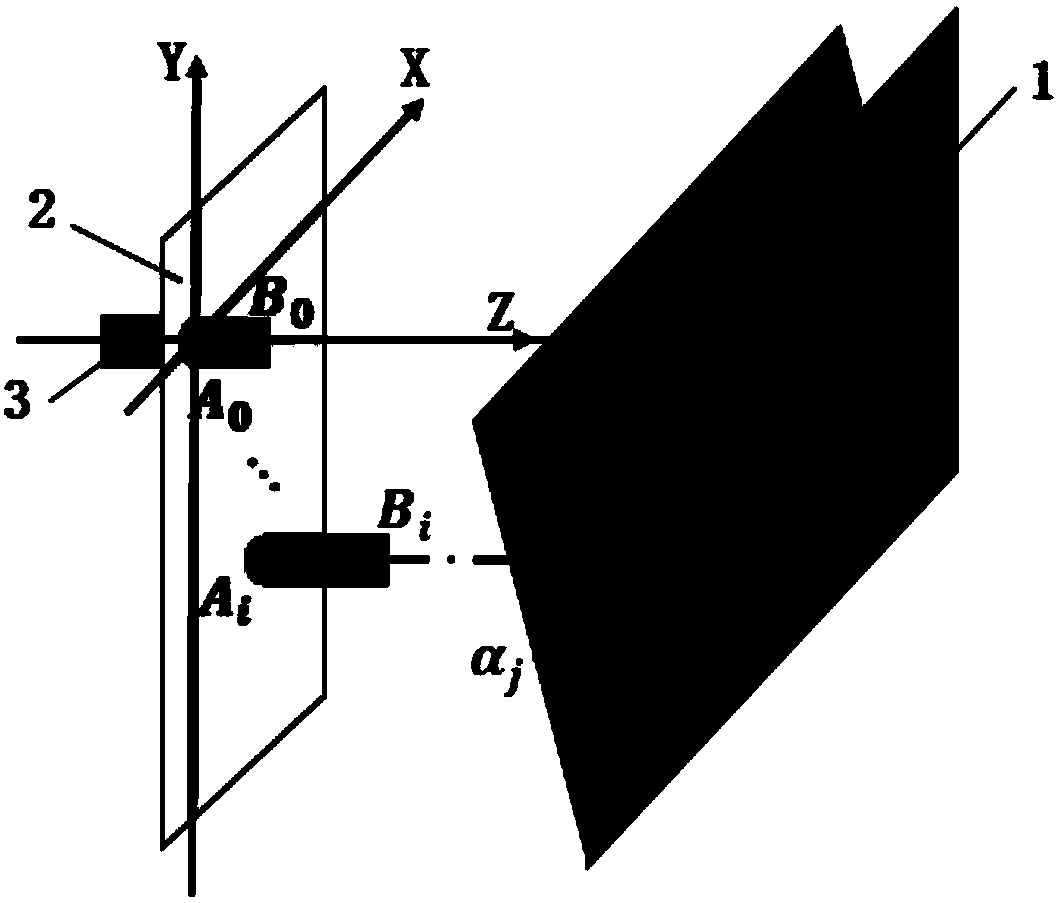

[0035] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0036] Figure 5 The overall flowchart for the spatial geometry calibration of the eddy current displacement sensor array. The whole calibration process includes two steps: the space geometry calibration of the XOZ projection surface of the eddy current displacement sensor array and the space geometry calibration of the YOZ projection surface of the eddy current displacement sensor array. The first step is that the probe is aligned with the plane calibration plate, and the plane calibration plate is controlled to rotate multiple times along a horizontal edge, and the rotation angle and the degree of the eddy current displacement sensor are read each time, and the two-axis directions of any two probes in the eddy current displacement sensor array are compared. To achieve spatial geometry calibration, the second step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com