Semi-active electric vortex laminated rubber support system

A laminated rubber bearing, semi-active technology, applied in the direction of building components, building structure, earthquake resistance, etc., can solve the problems of oil leakage of hydraulic viscous damper, affect design analysis, difficult to adjust, etc., to ensure safety and improve The effect of shock isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

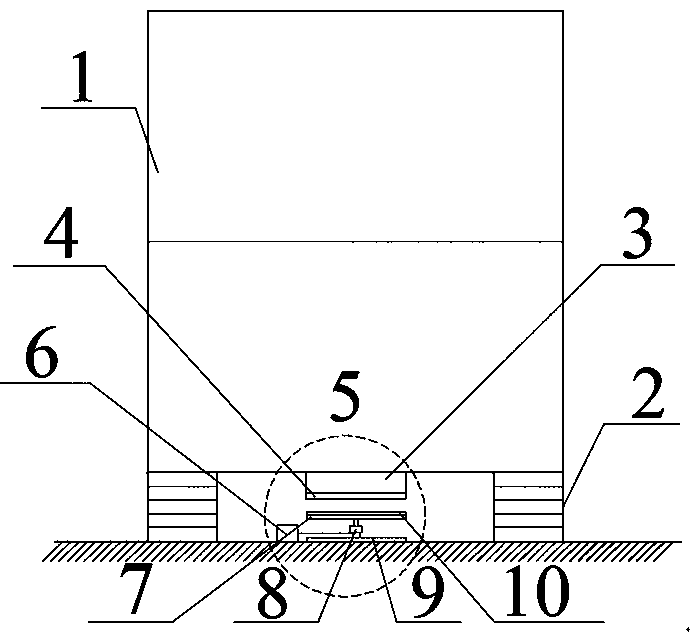

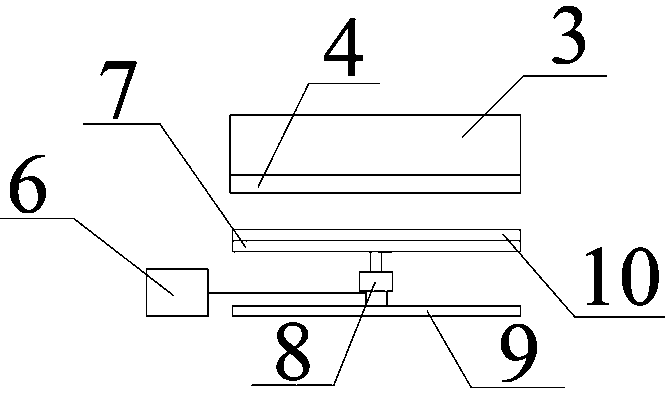

[0018] Example 1: If Figure 1 to Figure 2 As shown, a semi-active eddy current laminated rubber bearing system of the present invention is composed of a laminated rubber bearing 2 and a semi-active eddy current damping system 5, wherein:

[0019] The semi-active eddy current damping system 5 is composed of a fixed part 3 , a permanent magnet 4 , a data acquisition and analyzer 6 , a magnetic guide plate 7 , an actuator 8 , a bottom fixed plate 9 and a conductor plate 10 .

[0020] The fixing part 3 is fixedly installed on the bottom of the superstructure 1, and the permanent magnet 4 is fixed on the bottom of the fixing part 3 with bolts.

[0021] When an earthquake occurs, the permanent magnet 4 vibrates horizontally and cuts the magnetic induction line with the conductor plate 10. The seismic energy is consumed by the heating of the conductor plate 10. The function of the magnetic guide plate 7 is to enhance the magnetic field strength and increase energy consumption. Effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com