Star polygonal winding with m-phase power sources for asynchronous motor

A technology of asynchronous motors and star polygons, applied to asynchronous induction motors, the shape/style/structure of winding conductors, electrical components, etc., can solve problems such as inability to study, damage to the normal operation of power systems and electrical equipment, and achieve reduction Noise, reduction of ferromagnetic saturation, and reduction of harmonic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

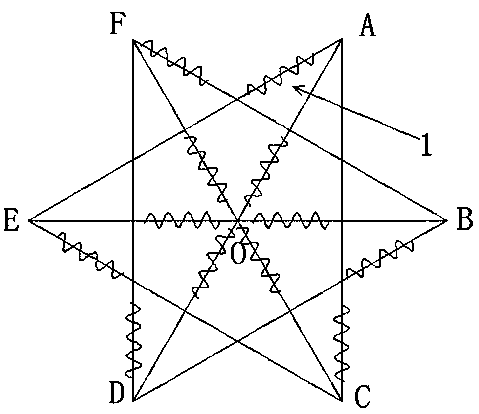

[0019] Specific implementation: combination figure 1 To illustrate this embodiment, a power supply of this embodiment is an m-phase asynchronous motor star polygon winding 1, the number of phases is A, B, C, D, E, F, and the star hexagon winding 1 has half the number of asynchronous motors The winding 1 in the slot is connected into a hexagon according to the number of phases of the power supply, and the winding 1 in the other half of the slot is connected in a star shape to form a mixed connection winding.

[0020] This embodiment is a twenty-four-phase system from the inside of the motor, and a six-phase system from the outside of the motor. The winding of this connection method greatly reduces the harmonic components, and not only reduces the noise, vibration, stray loss, and harmonics. Torque can also save effective materials, which has practical engineering application significance. This motor can inject third harmonic current at the same time when the fundamental current is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com