Glass substrate wiring structure, glass substrate and display device

A glass substrate and wiring structure technology, which is applied in the field of liquid crystal display, can solve the problems that the wiring resistance cannot be improved, the wiring space is limited, and the charging effect of the glass substrate cannot be improved, so as to achieve the effect of improving the charging effect and reducing the wiring resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

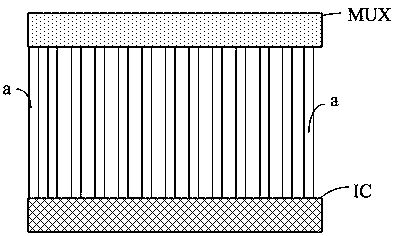

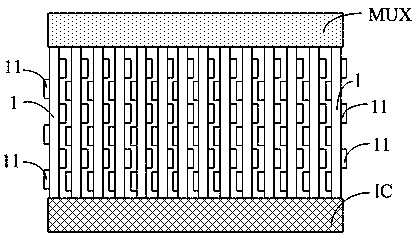

[0021] Such as figure 2 As shown, in Embodiment 1 of the present invention, a wiring structure of a glass substrate is provided, used between the demultiplexer MUX and the integrated circuit IC, including a plurality of connection lines 1, and the two ends of each connection line 1 are connected to MUX and IC, and a preset distance is reserved between any two adjacent connecting lines 1; where,

[0022] At least one connecting wire 1 is provided with one or more conductive protruding teeth 11, and each protruding tooth 11 on any connecting wire 1 is connected with its adjacent connecting wire 1 or each protruding tooth on the adjacent connecting wire 1 There is also a certain distance reserved between 11.

[0023] It can be understood that the convex tooth 11 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com