3D glass forming die structure

A glass forming and 3D technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of insufficient precision control, large product eccentricity, and high product defective rate, so as to improve smoothness, Effect of improving heating efficiency and reducing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

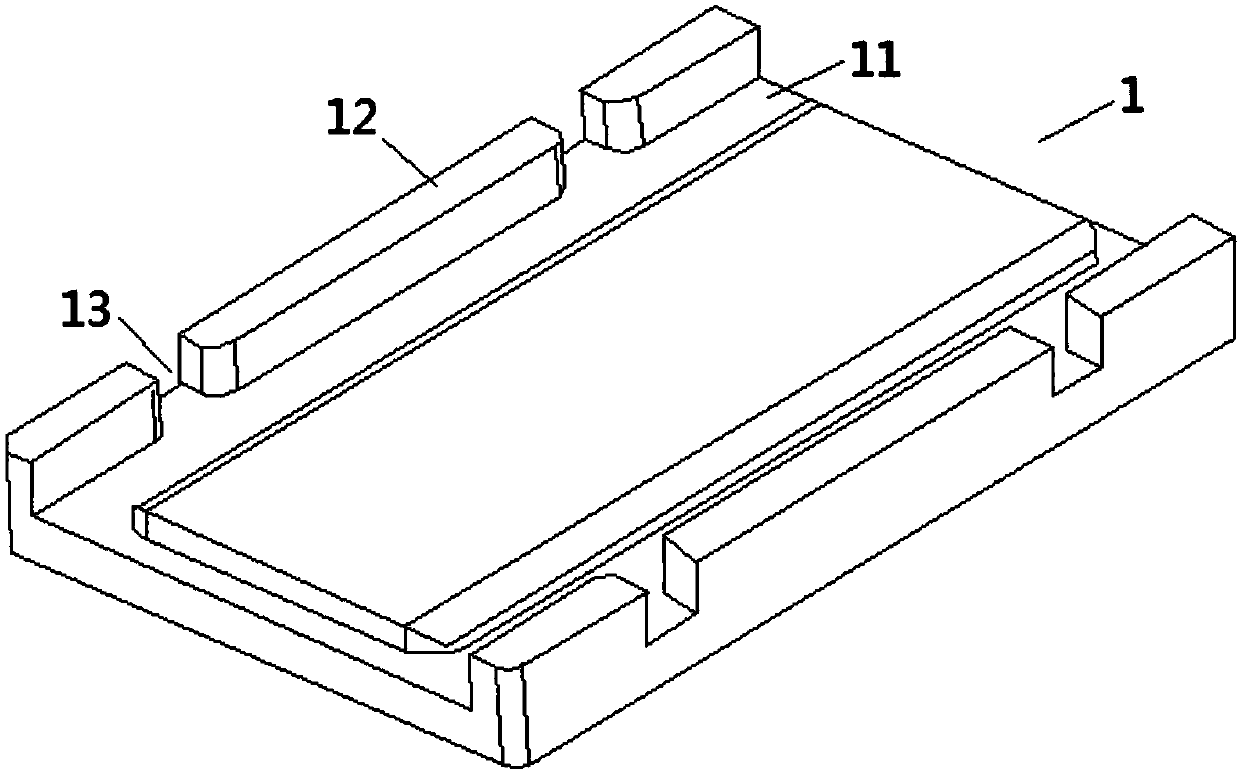

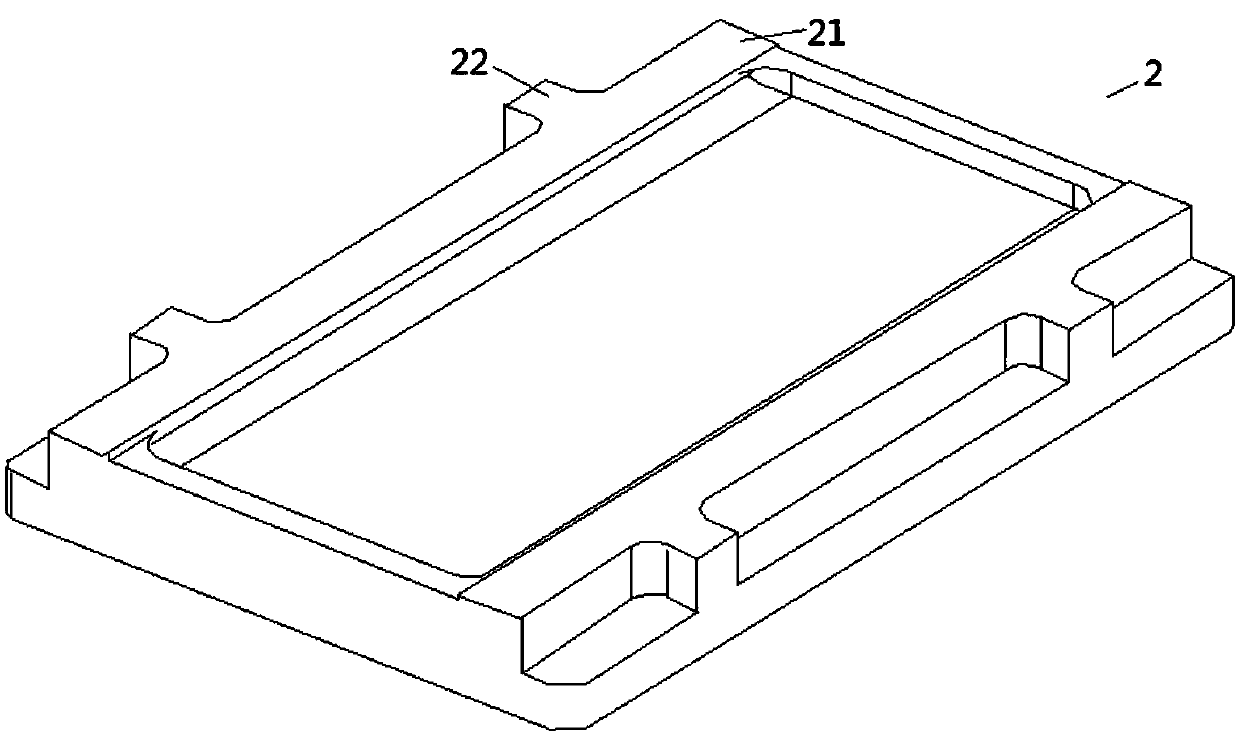

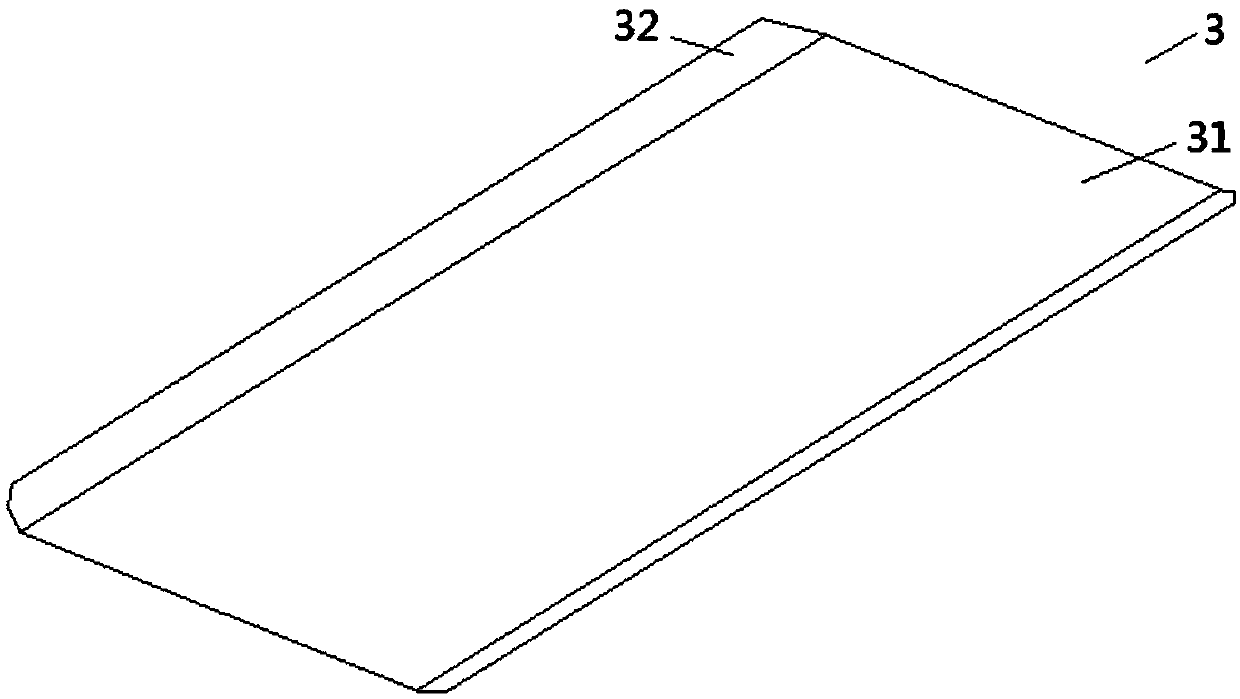

[0039] Such as Figure 1-4 As shown, the 3D glass forming mold structure includes a convex mold 1 and a concave mold 2 arranged up and down, the 3D glass 3 is sandwiched between the convex mold 1 and the concave mold 2, and the convex mold 1 is provided with two The sides of the 3D glass 3 are parallel to the grooves 11 located on both sides of the 3D glass 3, and the concave mold 2 is provided with corners 21 corresponding to the two grooves 11, and the 3D glass 3 includes The main body part 31 and the curved surface parts 32 arranged on both sides of the main body part.

[0040] Two locking edges 12 parallel to the groove 11 are arranged on both sides of the punch 1, and more than one lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com