Elevator safety clamp braking temperature rising measuring method

A measurement method and technology of safety gear, applied in elevators, transportation and packaging, etc., can solve the problems of changing the braking performance of safety gear, changing mechanical properties, and lack of effective means, so as to increase heat transfer efficiency, improve braking performance, increase The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

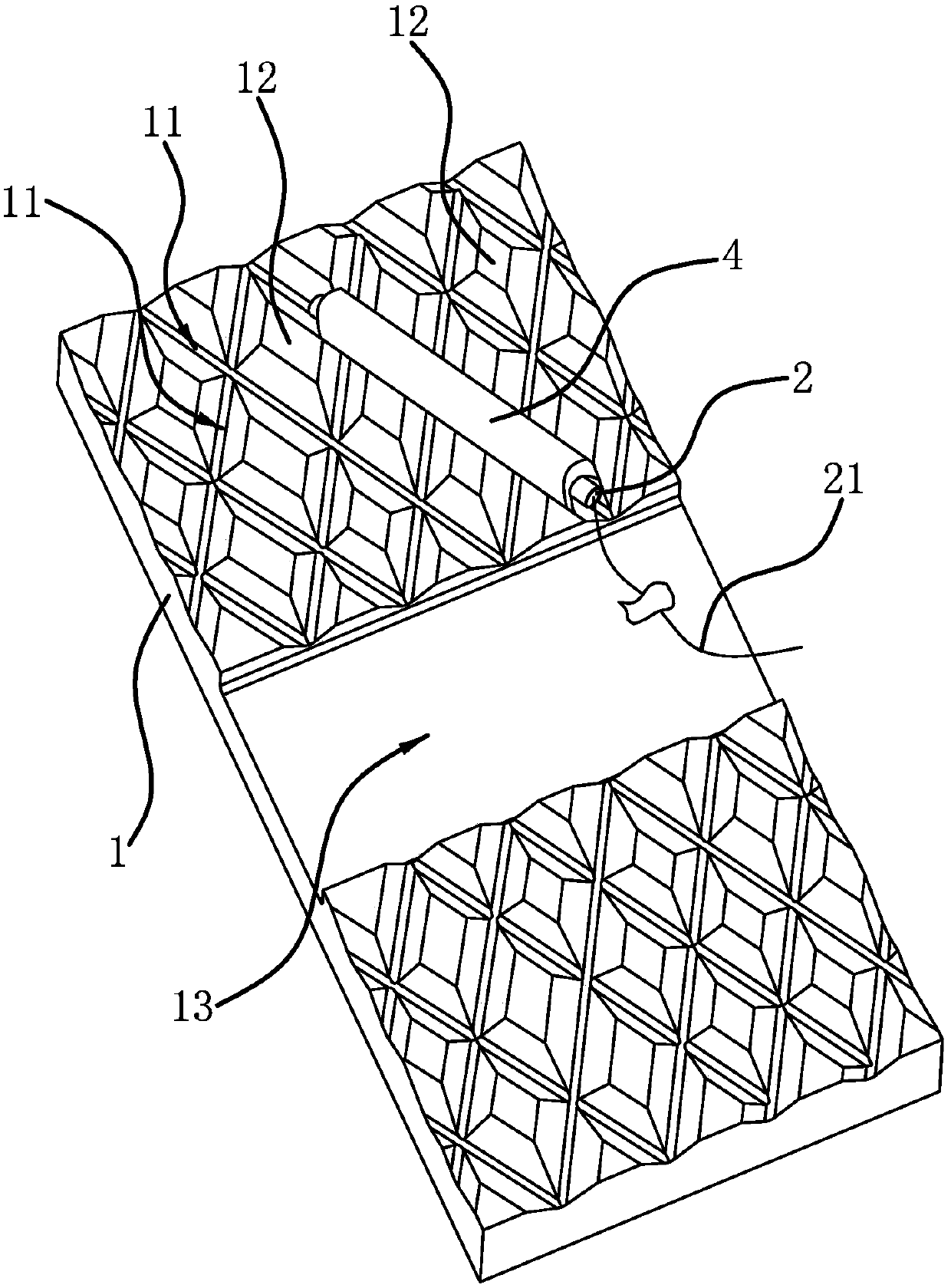

[0024] Such as figure 1 Shown, a kind of elevator safety gear braking temperature rise measuring method is characterized in that, comprises the following steps:

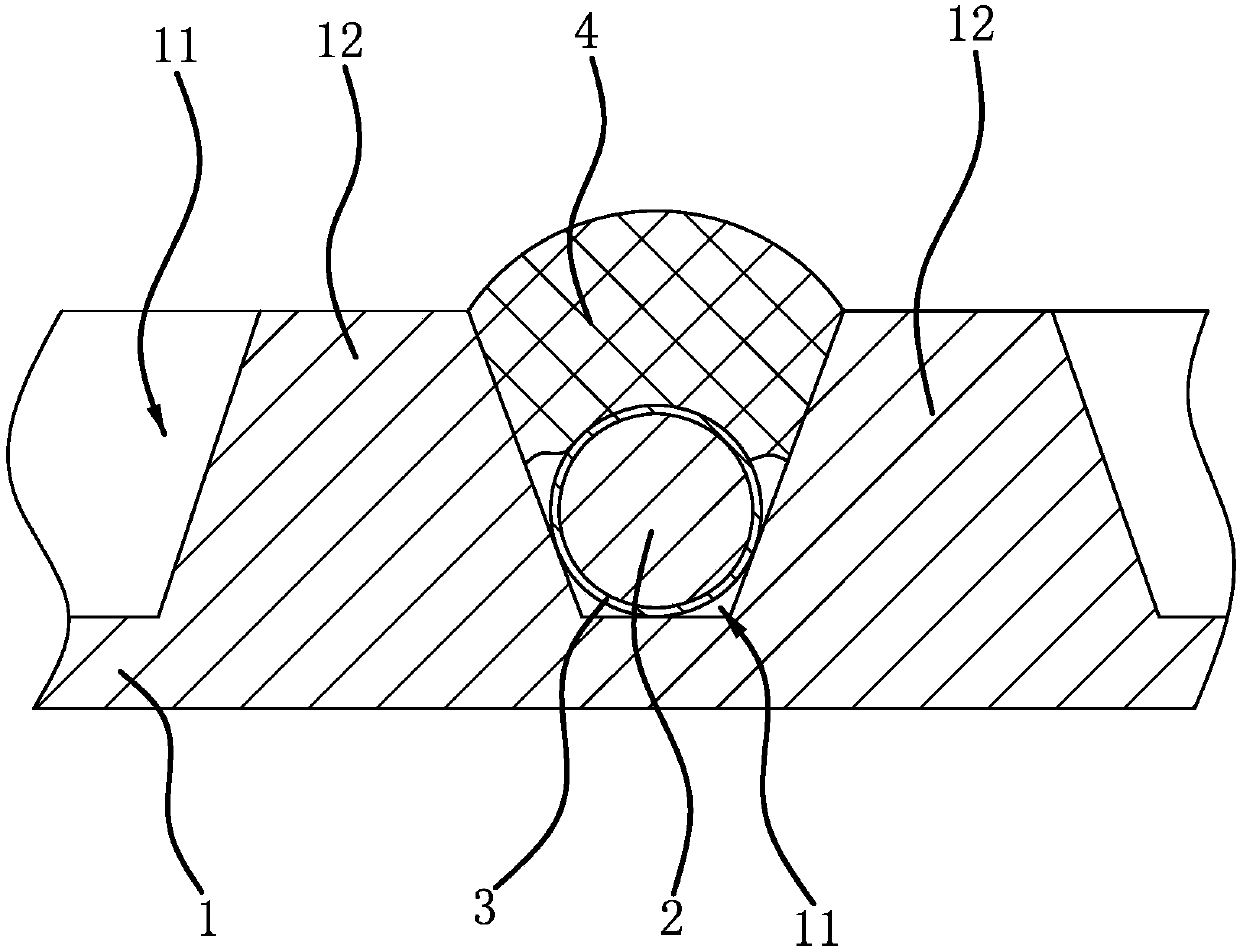

[0025] A. Preparation of safety gear: combined figure 2 As shown, a number of gathering grooves 11 are provided on the working surface of the rectangular block-shaped safety gear clamp block 1. The gathering grooves 11 are divided into two groups, and the gathering grooves 11 are all inclined relative to the length direction of the clamp block 1, and one group is inclined toward the clamp block 1. The left edge is inclined, and the other group is inclined to the right edge of the clamp block 1, and several gathering grooves 11 of each group are parallel to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com