Picking and stuffing injecting method of dough with stuffing

A dough and stuffing technology, applied in the fields of dough processing, baking, food science, etc., can solve the problems of being unsuitable for home or restaurant use, low degree of automation, reducing production efficiency, etc., to achieve large bearing capacity, improve work efficiency, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

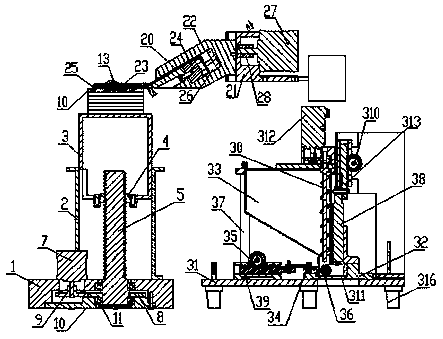

[0046] Such as Figures 1 to 7 Shown, a kind of picking up of filling dough, filling method, comprises the following steps:

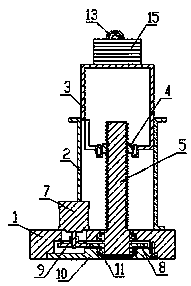

[0047] X1, laying stacked dough 10 on the upper surface of lifting table 3;

[0048] X2, the servo motor 7 drives the screw 5 inserted in the bearing 11 to rotate;

[0049] X3, the rotation of the lead screw 5 is transformed into the upward linear motion of the lifting table 3;

[0050] X4, the lifting platform 3 moving upward pushes the first dough 10 to the bottom of the needle plate 23;

[0051] X5, the servo motor 7 stops;

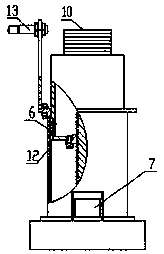

[0052] X6, the needle plate 23 is located above the dough 10, and the rotating shaft of the motor 27 rotates in the eccentric wheel 28, so that the fixed plate 22 connected to the eccentric wheel 28 moves vertically downward until the needle plate 23 movable on the fixed plate 22 moves When the upper surface of the first dough 10 is reached, the motor 27 stops;

[0053] X8, the telescopic device 24 on the fixed plate 22 pus...

Embodiment 2

[0067] Such as Figures 1 to 7 Shown, a kind of picking up of filling dough, filling method, comprises the following steps:

[0068] X1, laying stacked dough 10 on the upper surface of lifting table 3;

[0069] X2, the servo motor 7 drives the screw 5 inserted in the bearing 11 to rotate;

[0070] X3, the rotation of the lead screw 5 is transformed into the upward linear motion of the lifting table 3;

[0071] X4, the lifting platform 3 moving upward pushes the first dough 10 to the bottom of the needle plate 23;

[0072] X5, the servo motor 7 stops;

[0073] X6, the needle plate 23 is located above the dough 10, and the rotating shaft of the motor 27 rotates in the eccentric wheel 28, so that the fixed plate 22 connected to the eccentric wheel 28 moves vertically downward until the needle plate 23 movable on the fixed plate 22 moves When the upper surface of the first dough 10 is reached, the motor 27 stops;

[0074] X8, the telescopic device 24 on the fixed plate 22 pus...

Embodiment 3

[0092] Such as Figures 1 to 7 Shown, a kind of picking up of filling dough, filling method, comprises the following steps:

[0093] X1, laying stacked dough 10 on the upper surface of lifting table 3;

[0094] X2, the servo motor 7 drives the screw 5 inserted in the bearing 11 to rotate;

[0095] X3, the rotation of the lead screw 5 is transformed into the upward linear motion of the lifting table 3;

[0096] X4, the lifting platform 3 moving upward pushes the first dough 10 to the bottom of the needle plate 23;

[0097] X5, the servo motor 7 stops;

[0098] X6, the needle plate 23 is located above the dough 10, and the rotating shaft of the motor 27 rotates in the eccentric wheel 28, so that the fixed plate 22 connected to the eccentric wheel 28 moves vertically downward until the needle plate 23 movable on the fixed plate 22 moves When the upper surface of the first dough 10 is reached, the motor 27 stops;

[0099]X8, the telescopic device 24 on the fixed plate 22 push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com