Anti-corrosion connection plate without group holes

A connecting plate and group hole technology, applied in electrical components and other directions, can solve the problems of increasing the workload of screwing bolts, affecting the service life, and corrosion of the connecting plate, and achieving the effect of improving its own strength, delaying corrosion and reducing working force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The specific implementation manner of the present invention is described with reference to the accompanying drawings.

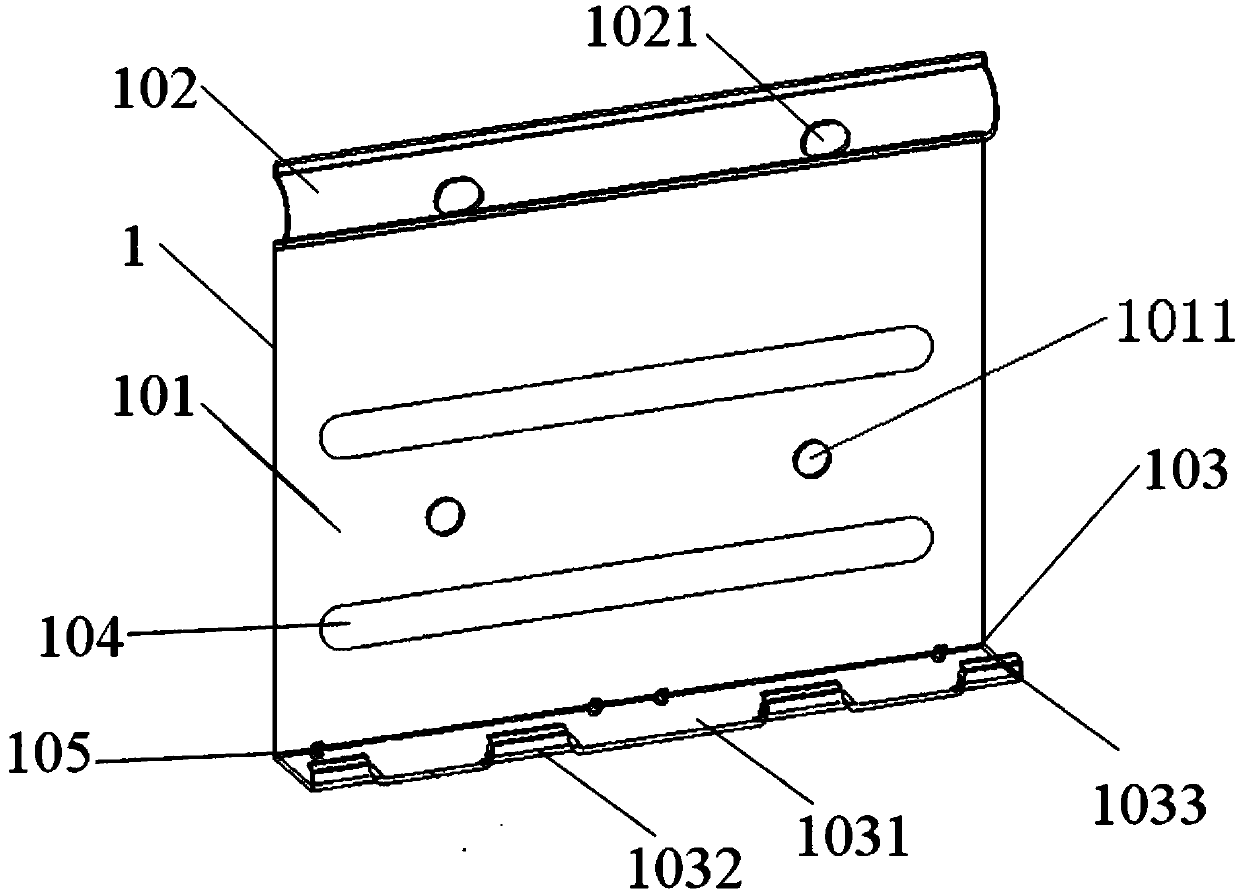

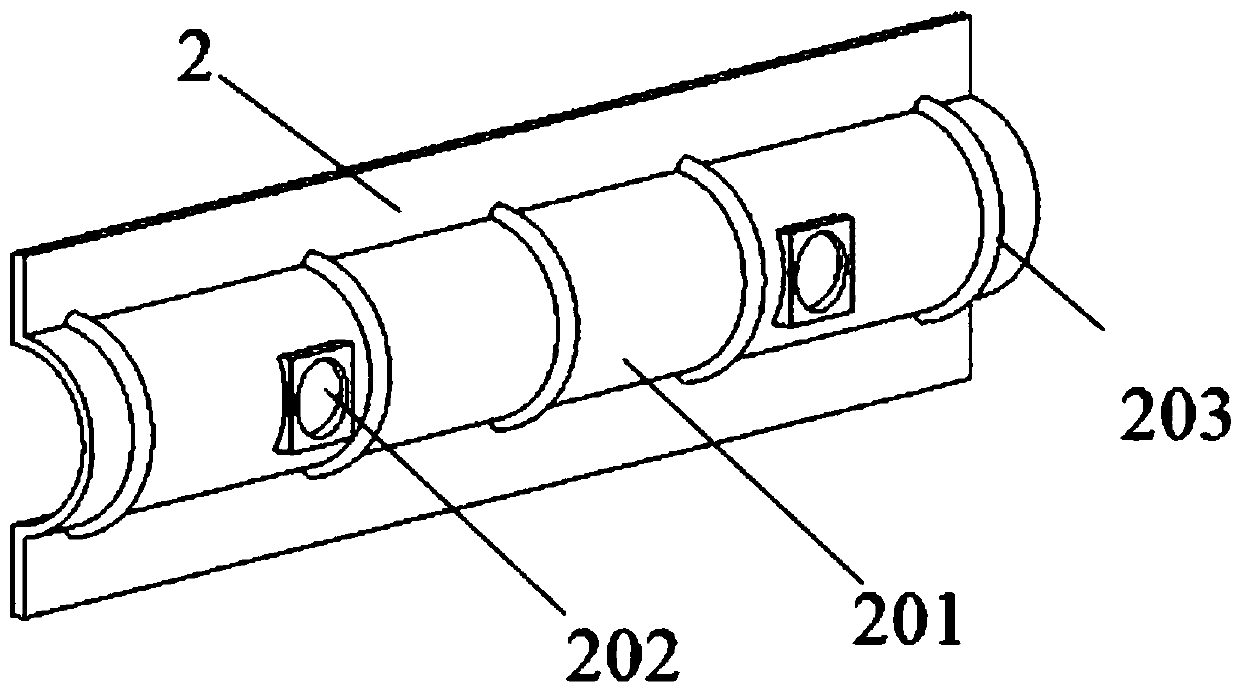

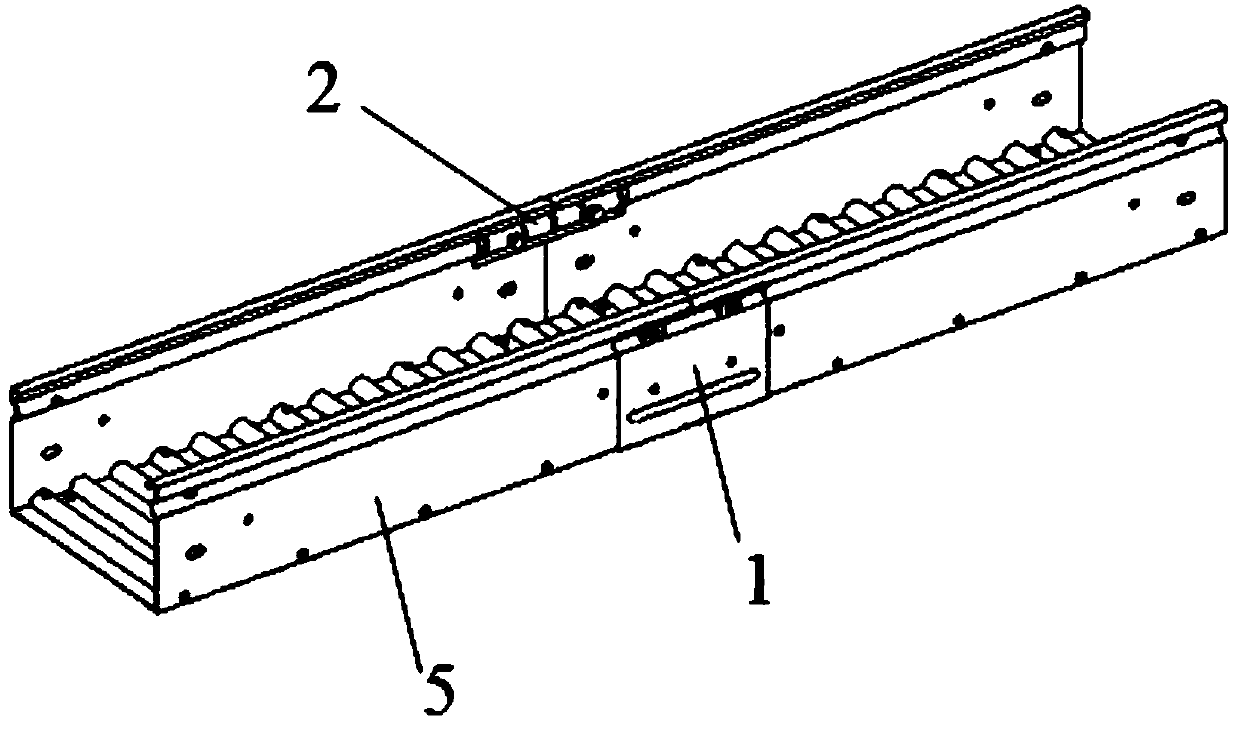

[0021] like Figure 1-4 As shown in the figure, the present invention includes an outer connecting sheet 1 and an inner connecting sheet 2, and the outer connecting sheet 1 is composed of side plates 101, R 1 The groove 102 and the bending portion 103 are connected into one body, and the side plate 101 is provided with several reinforcing ribs 104 ( figure 1 2 in), the R 1 A connection hole 1021 is provided on the groove 102, and an R 2 slot 201, the R 2 The slot 201 is provided with an inner connection hole 202 , and after the alignment of the connection hole 1021 and the inner connection hole 202 , the half-round nut 3 and the bolt 4 are used to realize the fixation with the bridge side plate 5 .

[0022] Specifically, the R 1 One end of the groove 102 is integrally connected with the upper end of the side plate 101 , and the other end extends t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com