Reverse thrust test device for engine thrust reverser life performance detection

A life performance and test device technology, which is applied in the field of aero-engines, can solve the problems that there is no aero-engine clamshell thrust reverser strength and fatigue life test device, thrust reverser strength or fatigue life test, etc., to avoid loading space Insufficient, simple structure, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

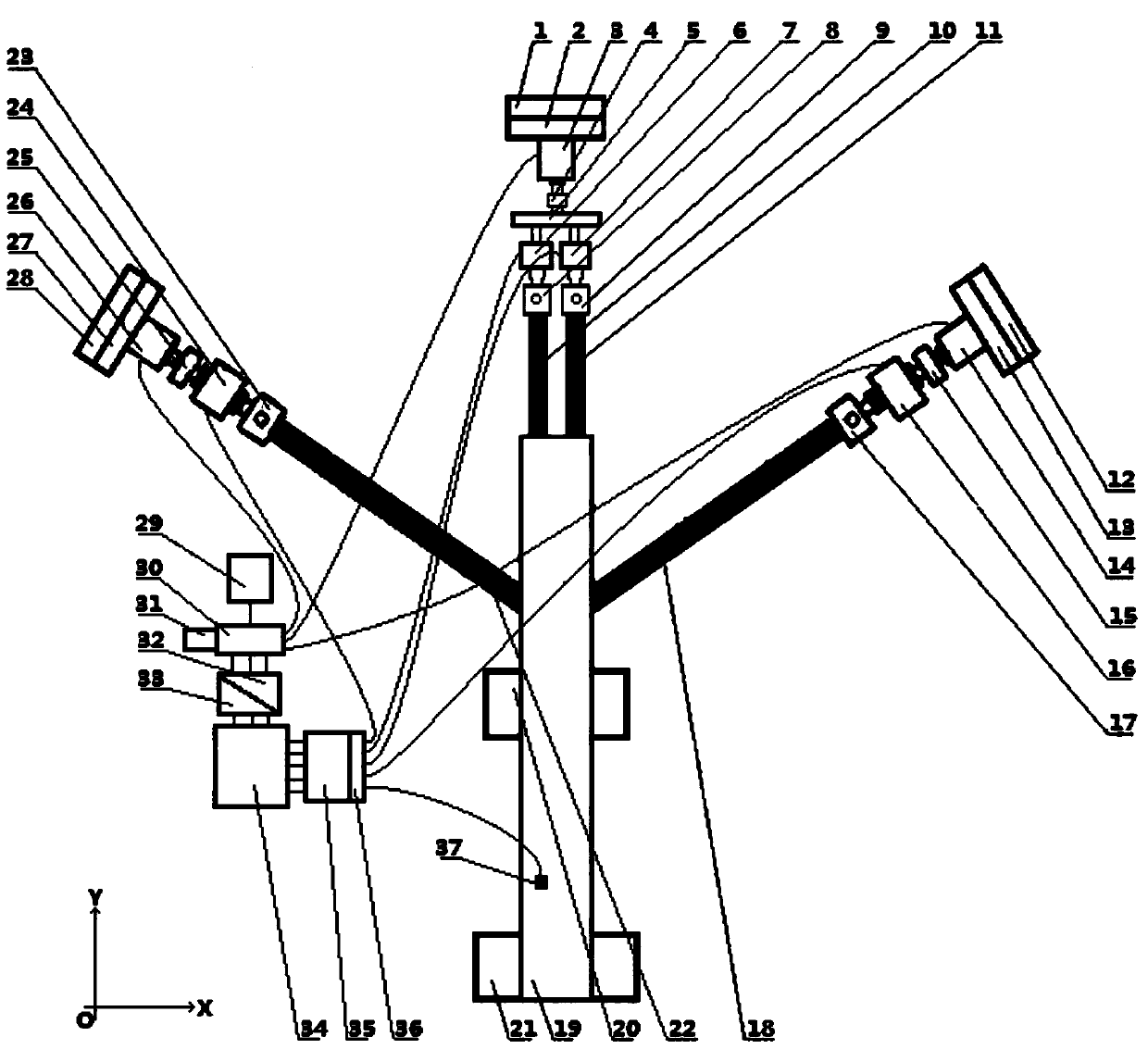

[0035] This embodiment adopts the thrust reverser test device designed by the present invention for the performance detection of the aeroengine thrust reverser to assess and detect the fatigue life of the engine clamshell thrust reverser. The test is carried out in the strength laboratory of the Product Design Center of 420 Factory The design of the entire thrust reverser test device is based on the maximum reverse thrust state of the engine thrust reverser, that is, the parameters of this test are all calculated according to this state, and the following test operation steps are also carried out according to this state.

[0036] In this embodiment, the test tooling and instrumentation used must meet the test requirements. Test tooling, including rear oil cylinder mounting seat 1, rear oil cylinder mounting plate 2, rear adapter 4, adapter plate 5, rear right joint 8, rear left joint 9, front right oil cylinder mounting seat 12, front right oil cylinder mounting plate 13, Fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com