Dust removal orifice building floor tiles

A technology for dust removal holes and floor tiles, which is applied in the field of building decoration materials, can solve problems such as inconvenience and hidden dangers, messiness, and hidden dangers, and achieve the effects of preventing the spread of dirt, protecting cleanliness, and quickly draining water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

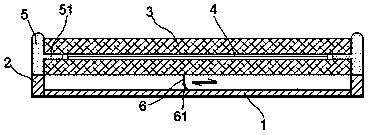

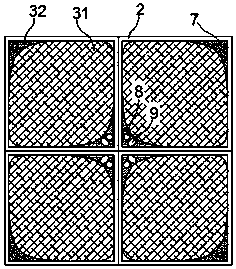

[0023] exist Figure 1 to Figure 3 In the shown embodiment, the dust-removing orifice building floor tile includes a base plate 1, a hollow surrounding edge 2 is fixedly arranged on the four sides of the base plate 1, and two layers of bearing plates 3 are arranged parallelly above the base plate 1, so that The bearing plate 3 includes a rhombus-shaped hard net plate 31, and the four corners of the hard net plate 31 are integrally provided with reinforcing angles 32; The upper edge of the surrounding edge 2 is flush; the space between the carrier plate 3 and the base plate 1 is suspended;

[0024] A cutting mesh 4 is arranged in the gap between the two layers of the carrying plate 3, and the cutting mesh 4 can freely translate along the surface of the carrying plate 3;

[0025] An annular regulating bag 5 is installed in the hollow area of the surrounding edge 2, and the regulating liquid is filled in the regulating bag 5; the upper ring edge of the regulating bag 5 is expo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com